Table of content

Introduction

The Alignment Challenge in Aluminum Manufacturing

Why Sales Agreements Matter for Production Planning

How Manufacturing Cloud Connects Sales & Production

Key Features for Aluminum Manufacturers

Benefits of Alignment Across Operations

Real-World Use Cases

Conclusion

Want to align your aluminum manufacturing operations for maximum efficiency?

1.Introduction

Aluminum manufacturing is a complex industry driven by fluctuating demand, variable production schedules, and long-term customer agreements. Customers—from automotive manufacturers to aerospace and packaging—depend on consistent supply, predictable pricing, and reliable delivery.

To deliver on these expectations, manufacturers must ensure that sales agreements, demand forecasts, and production planning are always aligned.

Salesforce Manufacturing Cloud bridges this critical gap by connecting front-office sales operations with back-office production teams, providing a unified view of demand, commitments, capacity, and inventory.

2. The Alignment Challenge in Aluminum Manufacturing

Aluminum manufacturers face unique challenges due to:

🔄 Long production cycles

Rolling, extrusion, and casting require advance scheduling and capacity planning.

⚙️ High energy consumption

Production planning impacts cost efficiency directly

📉 Volatile pricing & demand

Market fluctuations can disrupt planned production.

📑 Long-term contracts

Automotive and industrial customers commit to multi-month or multi-year agreements.

Without alignment between sales agreements and production, manufacturers face risks such as:

- Overproduction

- Underutilized capacity

- Missed delivery deadlines

- Contract penalties

- Margin leakage

3. Why Sales Agreements Matter for Production Planning

Sales agreements define:

- Volume commitments

- Price stability

- Delivery schedules

- Product quality/grade specifications

These details directly influence:

✔ Production volume

✔ Machine scheduling

✔ Raw material procurement

✔ Staffing and shift planning

✔ Energy usage planning

✔ Inventory strategies

However, many manufacturers track agreements manually—leading to misalignment and operational inefficiencies.

4. How Salesforce Manufacturing Cloud Connects Sales & Production

Manufacturing Cloud provides a single source of truth where:

- Sales

- Production

- Operations

- Finance

- Distributors

…all work from the same real-time data.

✔ Sales Agreement Workspace

Digitalized agreements store every detail including:

- Contracted quantities

- Pricing

- Terms

- Amendments

- Performance snapshots

This allows production teams to view actual commitments instantly.

✔ Integrated Forecasting & Demand Planning

Manufacturing Cloud combines:

- Sales forecasts

- Customer forecasts

- Historical data

- Distributor inputs

to provide a confident demand outlook.

Production teams rely on these numbers to schedule casting, rolling, extrusion, and finishing operations.

✔ Real-Time Changes Sync Across Teams

If sales updates an agreement due to:

- Customer requirement change

- Market shift

- Amended quantities

Production sees these changes immediately, preventing overproduction or shortages.

✔ Capacity Planning Alignment

Manufacturing Cloud connects with planning systems (ERP/MES) to:

- Evaluate available capacity

- Adjust work orders

- Optimize furnace and machine utilization

This ensures commitments can be met without overloading operations.

✔ Inventory & Material Requirement Alignment

Manufacturers gain visibility into:

- Raw material needs

- Alloy compositions

- Scrap recycling cycles

- Batch planning

Forecasts and agreements directly feed procurement and inventory planning.

5. Key Features for Aluminum Manufacturers

1. Sales Agreements Management

Digitized, real-time version of all customer commitments.

2. Account-Based Forecasting

Separate forecasts for alloy types, grades, and shapes (billets, sheets, coils, extrusions).

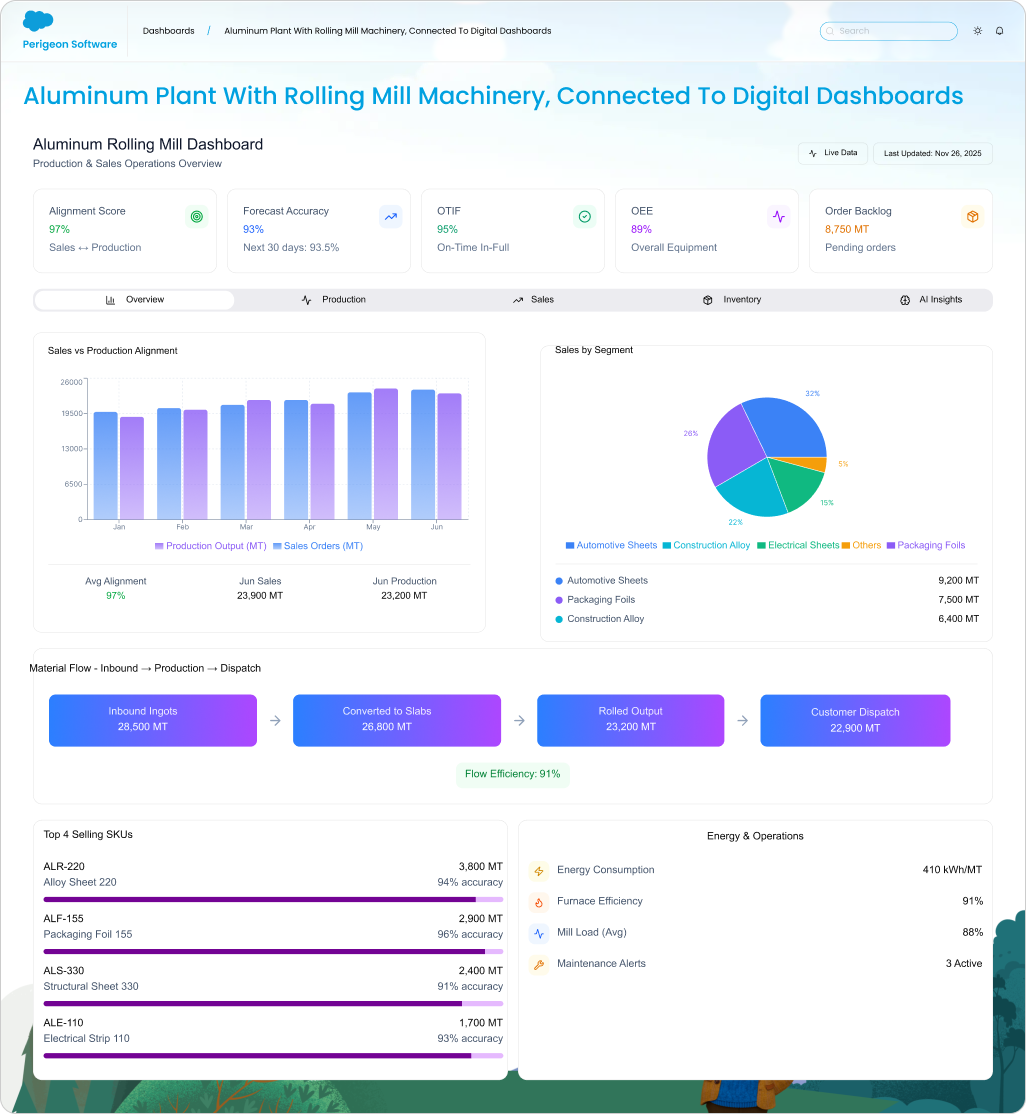

3. Performance Tracking Dashboards

Monitor contracted vs. actual production and supply.

4. Price & Volume Adjustments

Automated updates to accommodate fluctuations in LME and energy costs.

5. ERP/MES Integration

Seamless sync with SAP, Oracle, or any legacy systems.

6. Collaboration Tools

Sales and operations teams collaborate in real time.

6. Benefits of Alignment Across Operations

Aluminum manufacturers see major benefits:

📈 Improved Forecast Accuracy (25–35%)

Better demand planning leads to efficient production cycles.

🏭 Optimized Production Scheduling

Avoid bottlenecks and downtime with real-time data.

📦 Higher On-Time Delivery Rates

Meet customer commitments with confidence.

💰 Reduced Margin Leakage

Prevent errors caused by outdated agreement data.

🔄 Lower Inventory Costs

Produce based on accurate demand—not assumptions.

🤝 Stronger Customer Relationships

Customers receive consistent supply and transparent communication.

7. Real-World Use Cases

Use Case 1: Automotive Industry Supply

A large aluminum producer syncs long-term commitments with production to ensure steady output for automotive OEMs.

Use Case 2: Beverage Can Sheet Production

Sales agreements dictate monthly sheet demand; automated forecasting improves rolling mill planning.

Use Case 3: Extrusion Profile Manufacturing

Real-time alignment reduces waste and optimizes scrap recycling cycles.

8. Conclusion

Aligning sales agreements with production is no longer optional for aluminum manufacturers—it’s essential for efficiency, cost control, and customer satisfaction. Salesforce Manufacturing Cloud creates a unified operational ecosystem where sales commitments, forecasts, and production capacity work in harmony.

With real-time visibility and intelligent forecasting, aluminum manufacturers unlock smoother operations and more predictable revenue.

Want to align your aluminum manufacturing operations for maximum efficiency?

Perigeon Software specializes in implementing Salesforce Manufacturing Cloud for metals producers.

📩 Contact us today to get started.