Table of content

Introduction

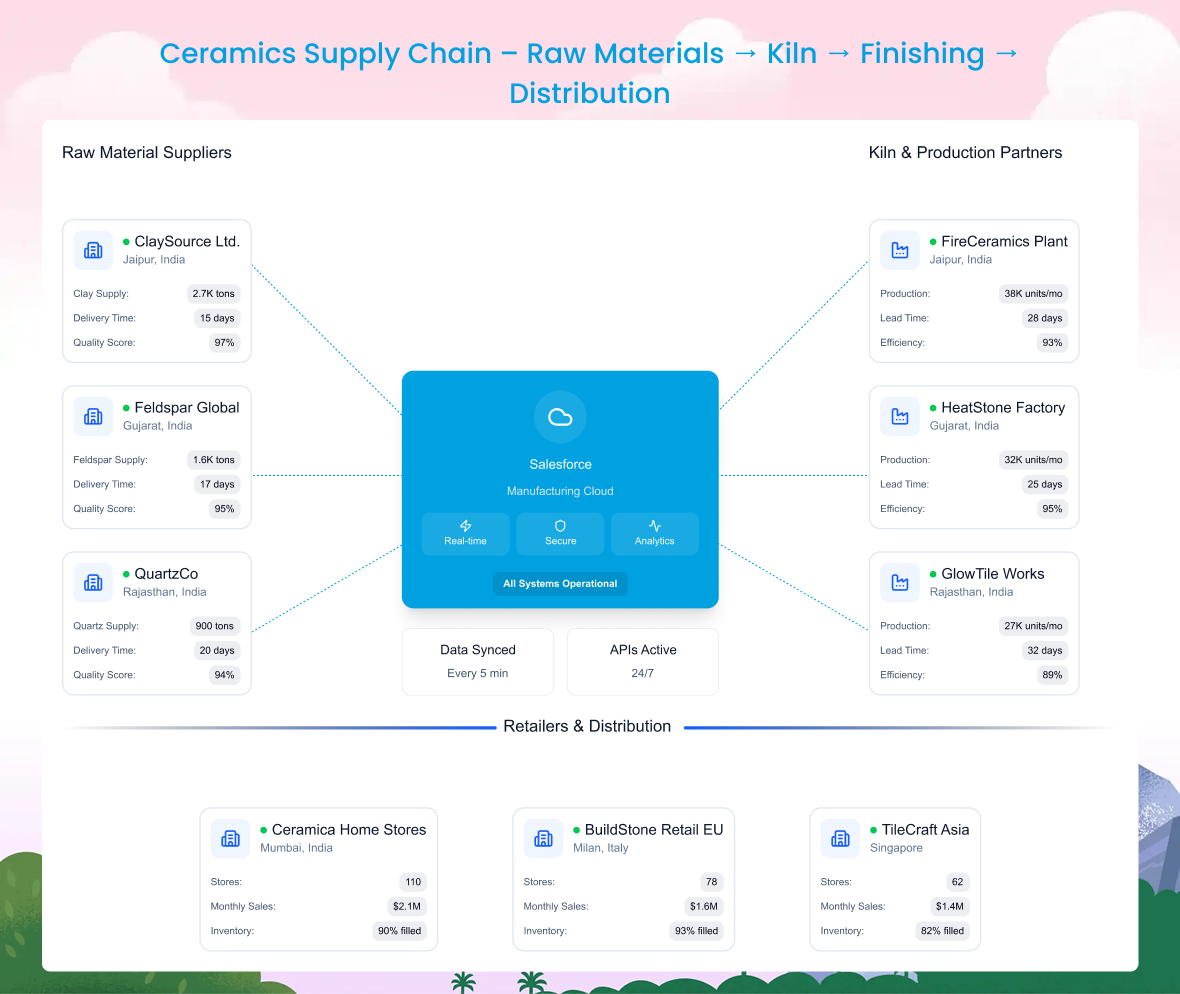

Ceramics Manufacturing Supply Chain Landscape

Why Supply Chain Complexity Is Higher in Ceramics

Key Supply Chain Challenges in Ceramics Manufacturing

How Salesforce Manufacturing Cloud Strengthens Ceramics Supply Chains

Case Study: Ceramics Manufacturer Builds a Resilient Supply Chain

The Future of Ceramics Supply Chains

Conclusion

1.Introduction

Ceramics manufacturing — spanning tiles, sanitaryware, technical ceramics, and advanced industrial components — depends on deep, multi-tier supply chains. From clay and feldspar to glazes, pigments, and packaging materials, supply reliability directly affects kiln schedules and delivery commitments.

According to PwC (2024), nearly 45% of ceramics manufacturers experience production delays due to supply chain disruptions, often caused by poor coordination between sales, procurement, and logistics.

Salesforce Manufacturing Cloud enables ceramics manufacturers to manage this complexity by connecting sales forecasts, supplier planning, distributor collaboration, and AI-driven risk insights in a single platform.

Ceramics Manufacturing Supply Chain Landscape

- Raw Materials: Clay, silica, feldspar, additives

- Production: Shaping → Drying → Firing (kilns) → Finishing

- Distribution: Regional distributors, exporters, project-based sales

- End Markets: Construction, infrastructure, industrial applications

? Any mismatch between demand and supply leads to kiln inefficiencies and delivery failures.

Why Supply Chain Complexity Is Higher in Ceramics

- Kilns run in fixed cycles — disruptions are costly

- Products vary widely by size, design, and finish

- Export-heavy markets require precise logistics planning

- Energy and fuel availability directly impact production schedules

Key Supply Chain Challenges in Ceramics Manufacturing

1. Multi-Stage Raw Material Sourcing

- Raw materials come from multiple regions

- Quality variation affects batch consistency

2. Energy-Intensive Kiln Operations

- Fuel shortages or energy price spikes disrupt firing schedules

3. Product Variety & Customization

- Thousands of SKUs increase planning complexity

4. Global Distributor & Export Dependencies

- Long lead times and port delays affect delivery timelines

5. Limited End-to-End Visibility

- Procurement, sales, and logistics operate in silos

How Salesforce Manufacturing Cloud Strengthens Ceramics Supply Chains

1. Unified Demand & Supply Visibility

- Links customer demand directly with procurement and production plans

- Creates a single source of truth across teams

2. Sales Agreement–Driven Material Planning

- Converts confirmed sales agreements into material demand signals

- Reduces speculative procurement

3. Supplier & Distributor Collaboration Portals

- Suppliers receive forecast visibility

- Distributors share real-time demand updates

4. ERP, MES & Logistics Integration

- Synchronizes Salesforce with ERP and shop-floor systems

- Aligns kiln schedules with inbound material availability

5. AI-Powered Risk & Disruption Prediction

- Einstein AI predicts:

- Supplier delays

- Logistics bottlenecks

- Energy-related production risks

Case Study: Ceramics Manufacturer Builds a Resilient Supply Chain

A tiles manufacturer exporting to 12 countries faced:

- Frequent raw material shortages

- Missed export delivery deadlines

After Salesforce Manufacturing Cloud:

- Supply disruptions reduced by 30%

- Inventory planning accuracy improved by 22%

- Distributor confidence increased significantly

The Future of Ceramics Supply Chains

- Digital Twin Kilns → Simulating supply-demand alignment

- AI Supplier Risk Scoring → Predicting failures before they occur

- Blockchain Traceability → Raw material provenance assurance

- Energy-Aware Planning → Sustainability-linked production optimization

Conclusion

Ceramics manufacturers need resilient, transparent supply chains to compete globally. Salesforce Manufacturing Cloud delivers:

- End-to-end demand & supply visibility

- Supplier and distributor collaboration

- ERP-aligned production planning

- AI-driven risk mitigation

With Salesforce, ceramics manufacturers transform fragile supply chains into strategic assets.

? Ready to strengthen your ceramics supply chain?

? Book a Manufacturing Cloud Strategy Session with Perigeon