Table of content

Introduction

Why Production Alignment Is Critical in Specialty Chemicals

The Challenges of Disconnected Production Planning

How Salesforce Manufacturing Cloud Creates End-to-End Visibility

Key Capabilities That Drive Production Alignment

Real-World Use Case: Aligning Production with Customer Commitments

Business Impact of Better Production Alignment

Why Partner with Perigeon Software

Conclusion

? Introduction

In the specialty chemicals industry, precision in production is everything.

Every batch, every formulation, and every raw material sourcing decision must align with actual customer demand — or it risks overproduction, waste, and lost revenue.

Yet many manufacturers struggle to align their production plans with real-time market changes, sales agreements, and distributor forecasts.

Salesforce Manufacturing Cloud bridges this gap by connecting data across sales, operations, and supply chain teams — creating a single source of truth that enables proactive, accurate production alignment.

“When production aligns with demand, manufacturers gain control, reduce waste, and deliver with precision.”

⚗️ Why Production Alignment Is Critical in Specialty Chemicals

Unlike commodity chemicals, specialty chemical manufacturing deals with customized, small-batch production for specific applications — coatings, adhesives, additives, or composites.

Key factors that make alignment essential:

- High formulation variability (each customer has unique product requirements)

- Long production lead times

- Complex raw material dependencies

- Strict quality and safety regulations

Without accurate production planning, manufacturers risk:

- Stockouts of critical components

- Overproduction of niche formulations

- Compliance issues from last-minute scheduling

- Reduced profitability due to inefficiencies

When these contracts are managed manually or across multiple systems, errors, missed renewals, and disputes are inevitable.

⚠️ The Challenges of Disconnected Production Planning

Traditional planning systems often operate in silos:

- Sales forecasts are made in spreadsheets

- Operations rely on outdated ERP data

- Production teams plan based on incomplete demand visibility

This leads to:

- Inconsistent Forecasts – Sales projections don’t match actual orders.

- Delayed Adjustments – Market changes aren’t reflected in production schedules quickly.

- Lack of Accountability – No shared visibility across teams.

- Inefficient Inventory Management – Excess raw materials or finished goods.

The result? Misalignment between what’s sold, what’s planned, and what’s produced.

⚙️ How Salesforce Manufacturing Cloud Creates End-to-End Visibility

Salesforce Manufacturing Cloud provides a unified data model that links sales, account forecasts, and production requirements.

It ensures every department — from sales to operations — works from the same set of real-time data.

With its powerful analytics and integration capabilities, manufacturers can:

- Track sales agreements and their impact on production

- Adjust production plans instantly based on updated forecasts

- Align demand planning with distributor and partner inputs

- Gain visibility into material availability and capacity constraints

? Key Capabilities That Drive Production Alignment

1️⃣ Unified Sales and Operations Planning (S&OP)

Manufacturing Cloud brings sales and operations data together into a unified workspace.

This allows teams to coordinate better, ensuring that sales commitments translate directly into production schedules.

Benefits:

- Shared visibility across departments

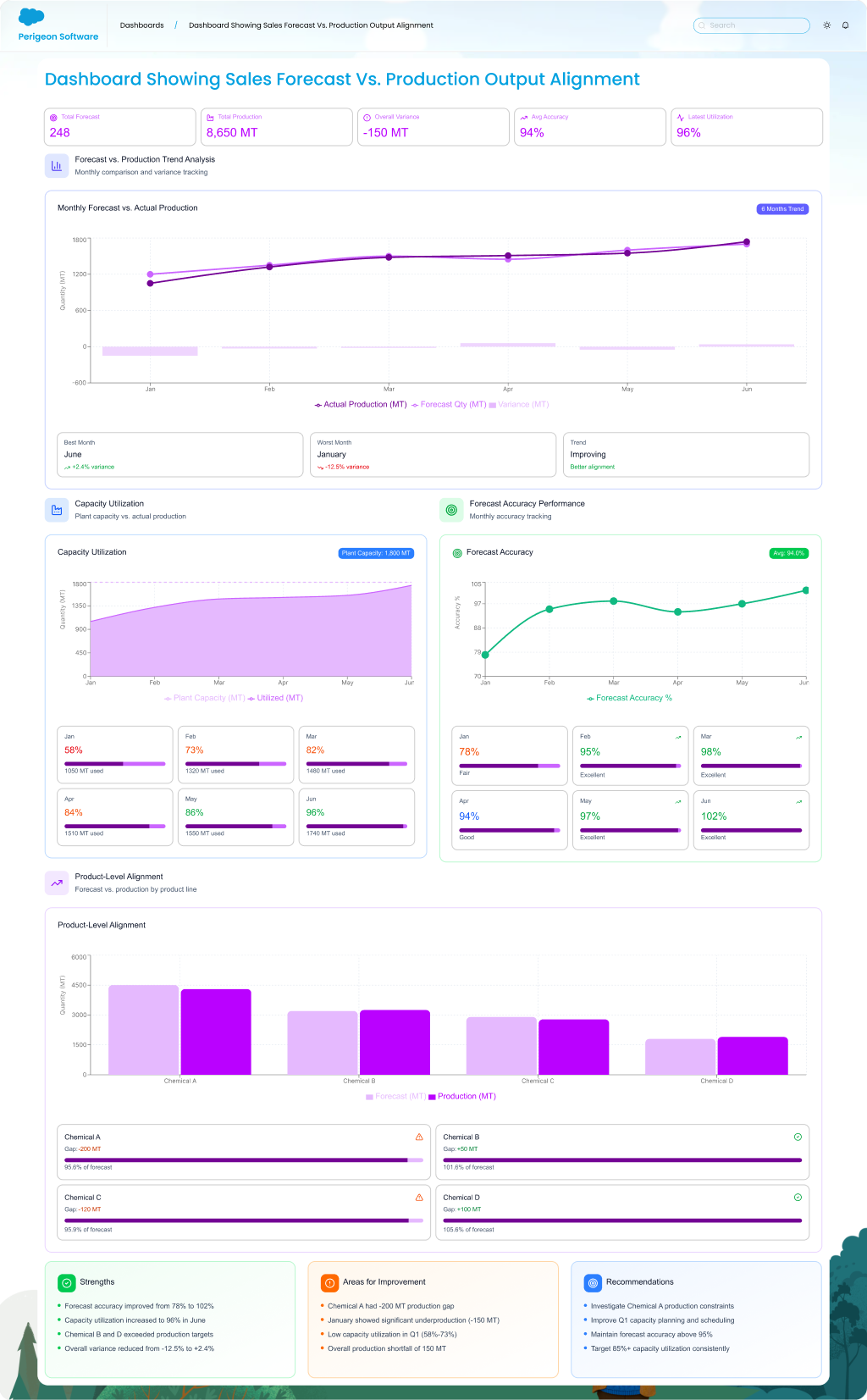

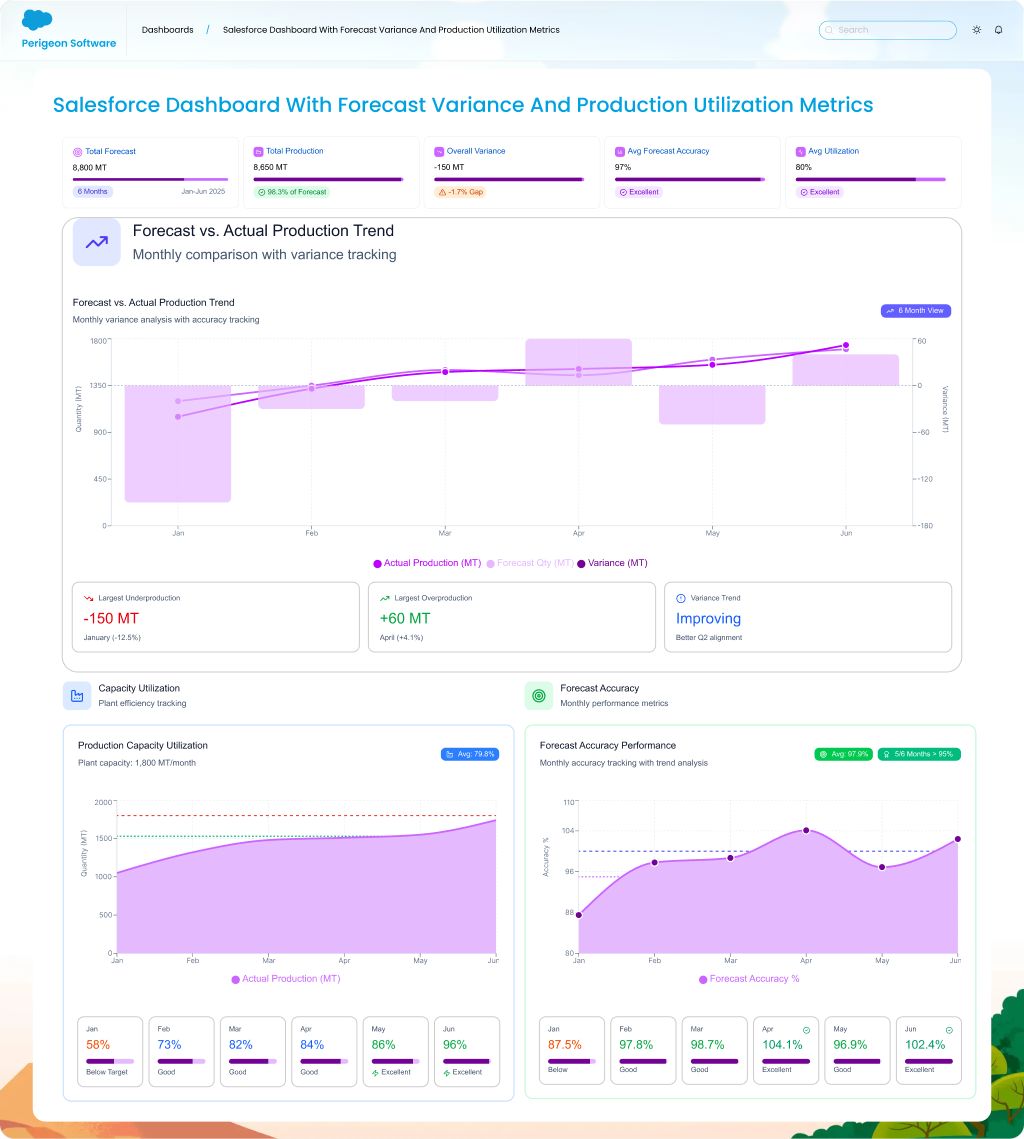

- Integrated dashboards showing demand, capacity, and fulfillment

- Improved responsiveness to market shifts

2️⃣ Real-Time Forecast Adjustments

Salesforce connects forecasts directly to production metrics. When sales teams update projections or customers modify orders, production plans automatically adjust.

Outcome:

- Real-time synchronization of production demand

- Reduced forecast variance

- Improved production efficiency and on-time delivery

3️⃣ Contract and Demand Linkage

In specialty chemicals, production often ties to contract-based commitments and volume agreements.

Manufacturing Cloud links these contracts directly to forecasts — ensuring production reflects both current demand and contractual obligations.

Key Capabilities:

- Automated demand updates based on contract changes

- Real-time alerting for upcoming volume thresholds

- Integration with Salesforce CPQ for pricing and volume impact

4️⃣ Collaboration Across Supply Chain Partners

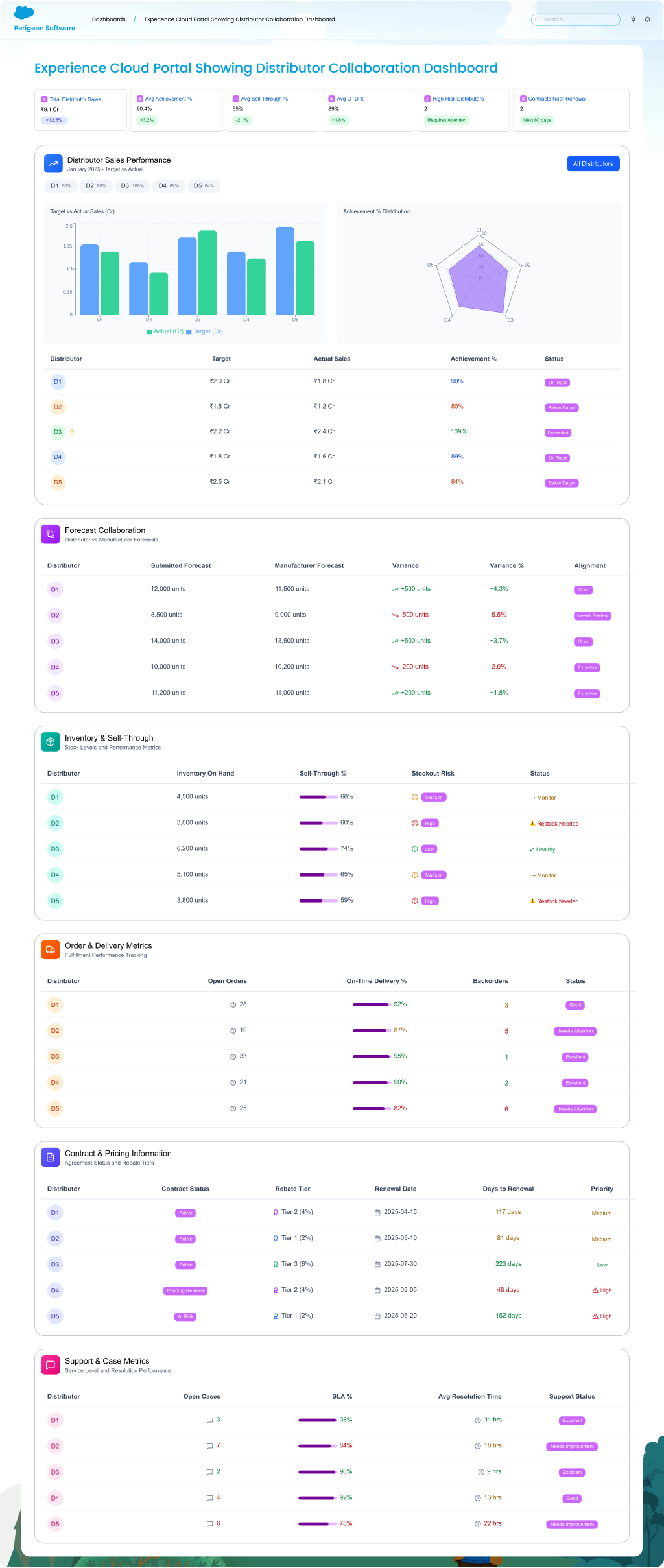

Through Salesforce Experience Cloud, manufacturers can share forecast data, production schedules, and order updates with distributors and suppliers securely.

This promotes:

- Better material planning with suppliers

- Real-time order tracking for distributors

- Reduced supply chain bottlenecks

? Real-World Use Case: Aligning Production with Customer Commitments

Scenario:

A specialty chemical manufacturer producing customized resins struggled to align its production plans with fast-changing customer demand from the automotive sector.

Challenges:

- Overproduction during demand slumps

- Underutilized production capacity

- Miscommunication between sales and production teams

Perigeon Software Solution:

- Implemented Salesforce Manufacturing Cloud with real-time forecasting

- Integrated sales agreements and ERP production data

- Built dashboards for forecast-to-production variance tracking

Results:

- Production forecast accuracy improved by 35%

- Inventory holding costs reduced by 22%

- Improved on-time delivery by 18%

? Business Impact of Better Production Alignment

By implementing Salesforce Manufacturing Cloud, specialty chemical manufacturers can achieve:

- 35% higher production forecast accuracy

- 22% reduction in waste and inventory costs

- 20% faster response to demand changes

- Complete visibility into forecast-to-actual variance

- Greater customer satisfaction through reliable fulfillment

These benefits translate directly to profitability, sustainability, and stronger long-term partnerships.

? Why Partner with Perigeon Software

Perigeon Software is a Salesforce Manufacturing Cloud consulting partner with deep experience in specialty and industrial manufacturing.

We help clients:

- Integrate sales forecasts and production data

- Configure Manufacturing Cloud for real-time S&OP alignment

- Enable seamless ERP and supply chain connectivity

- Provide training and support for cross-team adoption

Our goal is simple — to make your Salesforce environment the foundation for operational alignment and profitability.

? Conclusion

In a world where demand changes daily and production precision defines success, manufacturers can no longer rely on disconnected data.

Salesforce Manufacturing Cloud empowers specialty chemical manufacturers to unify forecasting, sales agreements, and production — achieving unprecedented visibility and alignment.

Partnering with Perigeon Software ensures this transformation is implemented seamlessly, driving operational excellence and long-term growth.