Table of content

Introduction

Why Forecast Accuracy Matters in Aluminum Manufacturing

Key Challenges Aluminum Producers Face in Forecasting

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

Features That Enable Aluminum Producers to Predict Demand

Real-World Business Impact

Why Now Is the Right Time for Digital Transformation

Conclusion

Looking to improve forecasting accuracy in your aluminum manufacturing operations?

1.Introduction

Aluminum manufacturing is a highly cyclical and demand-sensitive industry. From automotive and aerospace to construction and packaging, customer demand fluctuates rapidly — and even small forecasting errors can lead to major operational challenges.

Salesforce Manufacturing Cloud equips aluminum producers with the real-time data, predictive intelligence, and contract visibility needed to make forecasting more accurate and reliable.

This blog explores how the platform transforms the forecasting process for aluminum manufacturers and helps them stay competitive in volatile markets.

2. Why Forecast Accuracy Matters in Aluminum Manufacturing

Accurate forecasting is critical because aluminum production involves:

- High energy consumption

- Complex smelting and casting processes

- Long lead times

- Price-sensitive global markets

- Volatile raw materials (alumina, bauxite)

Even minor forecasting inaccuracies can lead to:

- Excess inventory and carrying costs

- Production slowdowns or machine idle time

- Higher scrap rates

- Supply chain delays

- Lost customer commitments

Forecast accuracy isn’t just a metric — it directly affects profitability, sustainability, and operational efficiency.

3. Key Challenges Aluminum Producers Face in Forecasting

1️⃣ Market Price Volatility

Aluminum prices frequently change based on global commodity markets.

2️⃣ Variation in Customer Ordering Patterns

OEMs and distributors often revise orders due to supply chain fluctuations.

3️⃣ Lack of Real-Time Data Visibility

Many aluminum manufacturers still rely on spreadsheets or outdated systems.

4️⃣ Large, Long-Term Contracts

Customer agreements include volume commitments that must be tracked continuously.

5️⃣ Multi-Stage Production Complexity

Demand forecasting must account for smelting, casting, extrusion, rolling, or finishing.

These challenges make manual forecasting inaccurate and inefficient.

4. How Salesforce Manufacturing Cloud Improves Forecast Accuracy

Salesforce Manufacturing Cloud centralizes sales, contractual, and operational data on a single platform — ensuring that demand forecasts are always current, collaborative, and data-driven.

Here’s how it transforms forecasting:

✔ Unified Sales Agreements & Demand Data

Manufacturing Cloud consolidates all customer agreements, including:

- Long-term contracts

- Volume commitments

- Pricing changes

- Delivery schedules

This ensures forecasts are based on real customer obligations, not assumptions.

✔ Real-Time Forecast Adjustments

As customers adjust orders — monthly, quarterly, or annually — forecast values update instantly.

Teams gain visibility into:

- Expected volumes

- Revised demand

- Current commitments

- Year-to-date consumption

No more outdated spreadsheets or misaligned planning.

✔ Account-Based Forecasting for Aluminum Customers

Aluminum producers often serve large OEMs or distributors.

Manufacturing Cloud enables forecasting by:

- Customer

- Product category (extrusions, coils, billets)

- Region

- Contract type

This improves forecasting accuracy at the micro-level.

✔ Integration With ERP & MES Systems

Manufacturing Cloud integrates seamlessly with:

- SAP

- Oracle

- Infor

- MES systems

This ensures real-time updates from the shop floor directly influence future forecasts.

✔ Predictive & AI-Driven Demand Insights

Salesforce Einstein AI analyzes:

- Historical demand

- Market conditions

- Seasonal patterns

- Customer behavior

and generates predictive demand forecasts — essential for high-volume production environments.

5. Features That Enable Aluminum Producers to Predict Demand

1. Sales Agreement Workspace

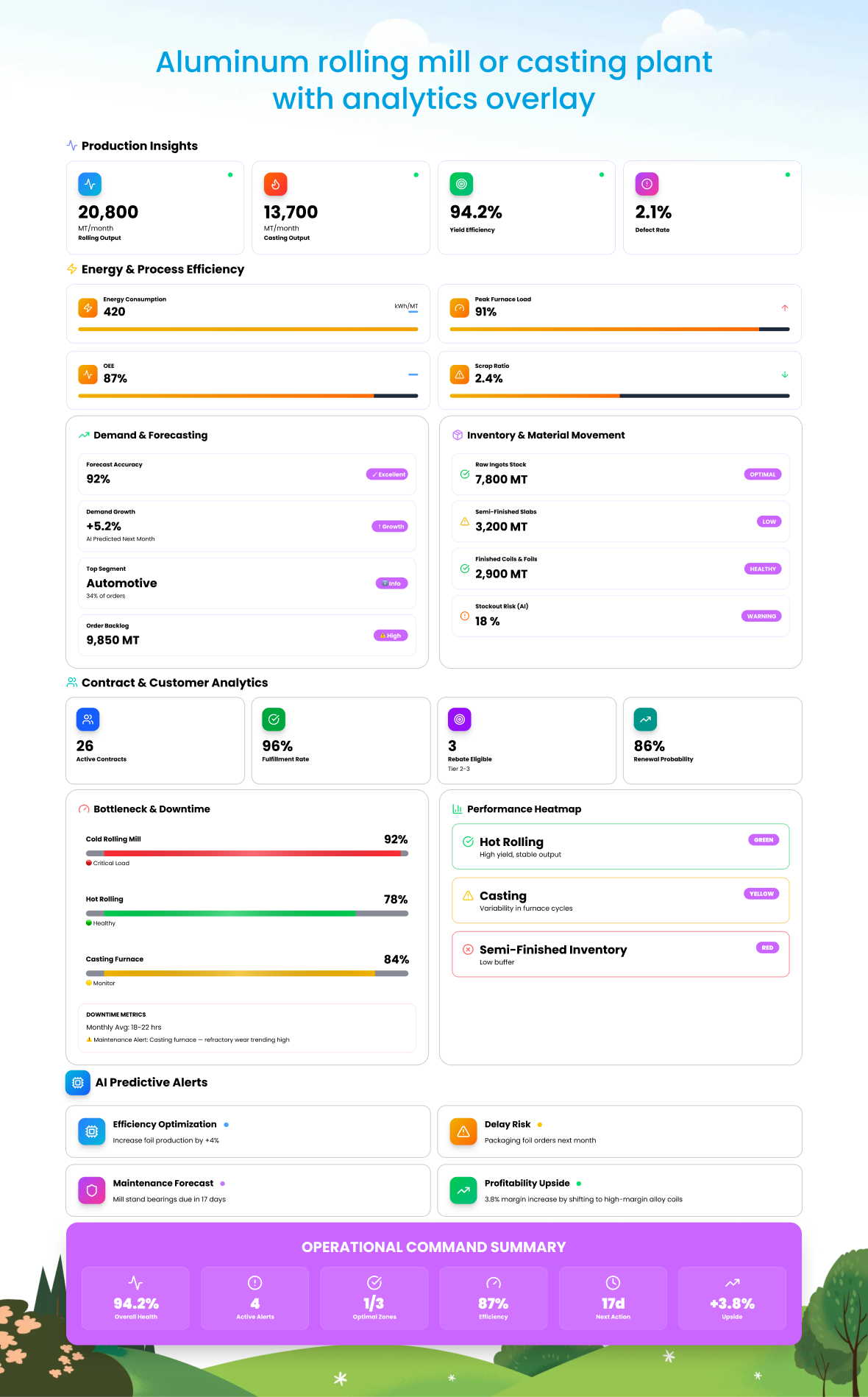

A single dashboard showing contract performance, forecasted quantities, and real-time updates.

2. Forecast Adjustment Engine

Automatically updates demand based on customer changes.

3. Collaborative Planning Tools

Sales, production, supply chain, and finance collaborate on forecasts in real time.

4. Rebate & Pricing Management

Helps match pricing models to market volatility.

5. Inventory & Capacity Insights

Ensures forecasts reflect actual plant capacity and inventory levels.

Together, these features provide a fully connected forecasting ecosystem.

6. Real-World Business Impact

Aluminum producers using Manufacturing Cloud report:

? 30–40% reduction in forecast deviation

Better alignment between actual vs expected demand.

? Improved capacity utilization

Plants can schedule production more accurately.

? Fewer production delays or changeovers

Because forecasts reflect real contract commitments.

? Stronger margin control

With better understanding of demand, pricing, and cost-to-serve.

? Increased collaboration across departments

Everyone works from the same real-time forecast.

7. Why Now Is the Right Time for Digital Transformation

The aluminum industry is experiencing:

- Increased global competition

- Supply chain volatility

- High energy costs

- Demand fluctuations

Digital forecasting tools like Salesforce Manufacturing Cloud help producers stay resilient, competitive, and efficient.

8. Conclusion

Demand forecasting is one of the most critical capabilities in aluminum manufacturing — and one of the most challenging. Salesforce Manufacturing Cloud provides a powerful solution by centralizing data, improving transparency, and enabling real-time adjustments that reflect market and customer changes.

With Manufacturing Cloud, aluminum producers can operate with greater predictability, stronger margins, and more confident decision-making.

Looking to improve forecasting accuracy in your aluminum manufacturing operations?

Perigeon Software specializes in Salesforce Manufacturing Cloud implementation tailored for metals and non-ferrous industries.

? Contact us today to get started.