Table of content

Introduction

The Unique Challenges of Perishable Supply Chains in Dairy Manufacturing

Why Visibility & Speed Matter in Dairy Supply Chains

Common Gaps in Traditional Dairy Logistics Systems

How Salesforce Manufacturing Cloud Empowers Perishable Supply Chains

Case Example: Reducing Spoilage with Salesforce Data Intelligence

KPIs to Measure Success in Perishable Supply Chains

The Future of Data-Driven Cold Chain Management

Why Partner with Perigeon Software for Salesforce Implementation

Conclusion

? Introduction

In dairy manufacturing, freshness isn’t a luxury — it’s a promise. From milk collection centers to processing plants, to cold storage and retail delivery, every minute matters. Even minor inefficiencies or visibility gaps can result in spoilage, compliance violations, and revenue loss.

According to Deloitte’s 2024 Global Dairy Outlook, nearly 18% of perishable dairy products are lost annually due to logistics inefficiencies and inadequate cold chain monitoring.

This is where Salesforce Manufacturing Cloud transforms operations — connecting the dots across supply, production, distribution, and retail networks in real time.

By leveraging AI, IoT integration, and predictive insights, Salesforce enables dairy manufacturers to maintain freshness, improve traceability, and reduce spoilage — all within a single intelligent platform.

? The Unique Challenges of Perishable Supply Chains in Dairy Manufacturing

Dairy manufacturing supply chains operate in a high-risk, time-sensitive environment. The key challenges include:

- ? Limited Shelf Life: Most dairy products (milk, curd, yogurt, cheese) require delivery within 24–72 hours.

- ?️ Temperature Sensitivity: Even a 2°C variation can compromise product quality.

- ? Complex Logistics: Multi-tier distribution (farm → plant → distributor → retailer).

- ? Compliance Pressures: Food safety and traceability standards demand precise monitoring.

- ? Lack of Real-Time Data: Most dairy operations still rely on batch reports or manual updates.

These challenges make real-time monitoring and proactive forecasting critical to maintaining efficiency and profitability.

⚙️ Why Visibility & Speed Matter in Dairy Supply Chains

In perishable product logistics, delays or blind spots can have cascading effects.

Impact of Poor Visibility:

- Increased spoilage due to temperature breaches

- Missed retail deliveries or product recalls

- Reduced consumer trust due to inconsistent quality

- Higher operational costs from emergency shipments

By enabling 360° visibility — from procurement to delivery — Salesforce empowers dairy companies to ensure fresh, safe, and timely delivery across every supply chain node.

⚠️ Common Gaps in Traditional Dairy Logistics Systems

Most dairy manufacturers struggle with:

- Disconnected Systems: ERP, transport management, and warehouse systems don’t communicate.

- Manual Temperature Tracking: Relying on physical logs instead of digital IoT sensors.

- Poor Distributor Coordination: Limited insight into downstream stock or delivery schedules.

- Reactive Problem-Solving: Issues are detected after spoilage occurs, not before.

Without integrated forecasting and real-time collaboration, operations remain reactive and opaque.

? How Salesforce Manufacturing Cloud Empowers Perishable Supply Chains

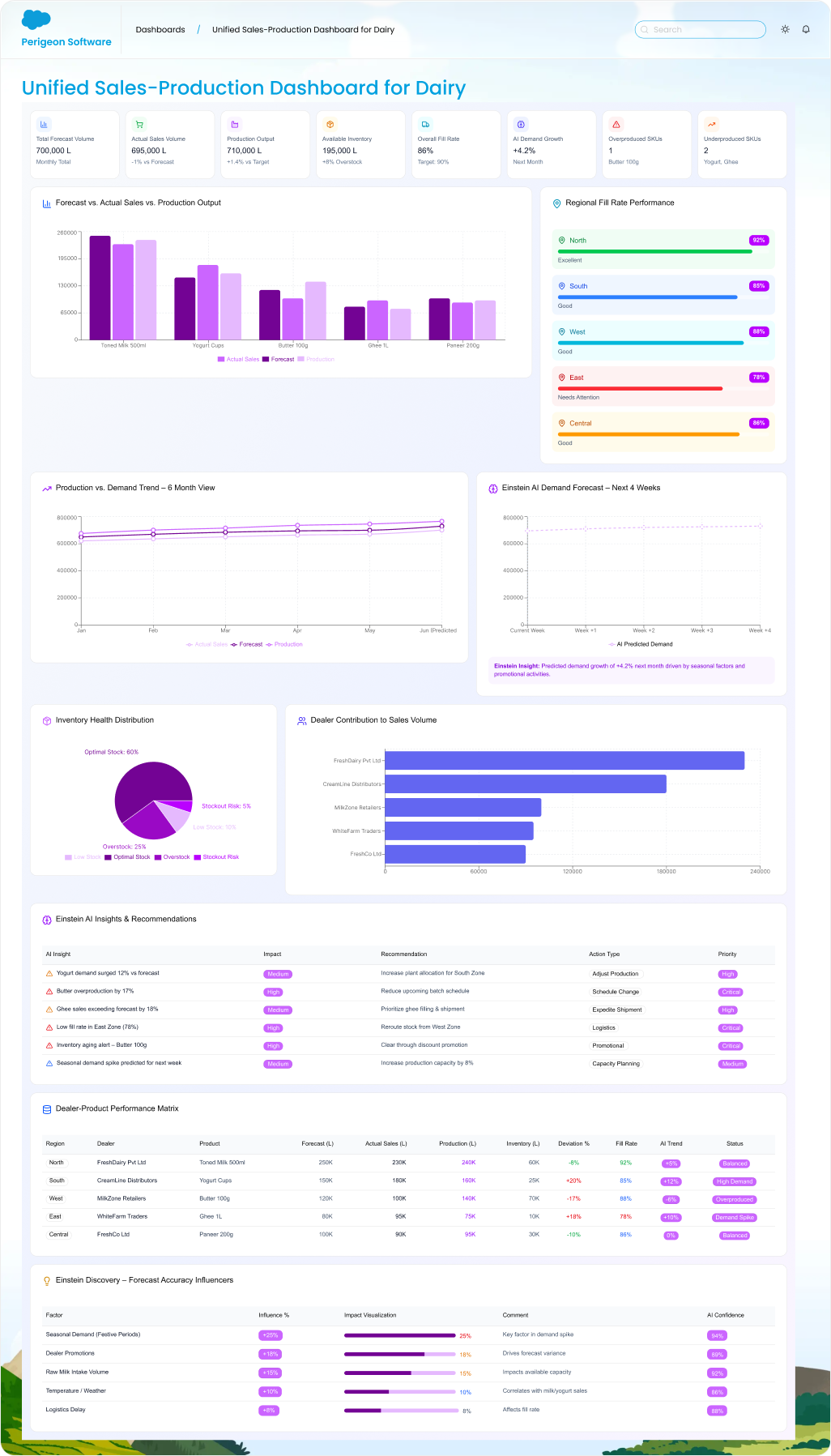

1️⃣ Unified Demand & Supply Data

Salesforce Manufacturing Cloud brings together:

- Real-time order visibility across B2B customers, distributors, and retail partners

- Dynamic production planning based on live sales data

- Automated alignment between milk procurement, processing, and distribution

…into a single unified platform.

Dairy companies gain:

- Sales agreements

- Production schedules

- Distribution commitments

2️⃣ Real-Time Temperature & Logistics Visibility

With IoT and logistics data integrated into Salesforce, manufacturers can track:

- Transport routes in real time

- Temperature logs from refrigerated trucks

- Delivery delays or deviations

AI alerts notify planners the moment a temperature deviation or delay occurs — helping prevent spoilage before it happens.

Stat: Companies that implemented Salesforce-integrated IoT monitoring reported 30% fewer cold chain violations (Source: Perigeon analysis, 2025).

3️⃣ AI Forecasting for Perishable Inventory

Salesforce Einstein AI predicts demand and spoilage risk by analyzing:

- Historical consumption trends

- Weather patterns and festival spikes

- Production line performance data

For example, if consumption for fresh yogurt peaks every weekend in urban markets, Einstein can auto-adjust forecasts to optimize milk processing schedules and dispatch planning.

4️⃣ Dealer, Retailer & Transport Collaboration

Manufacturing Cloud + Experience Cloud portals allow all stakeholders — from dairy distributors to retailers and logistics partners — to work off the same live data:

- Distributors update regional demand forecasts

- Retailers confirm stock levels and freshness

- Transporters share route and temperature updates

This ecosystem ensures the entire perishable network functions as one connected supply chain, reducing friction and improving accountability.

5️⃣ ERP & IoT Integration for End-to-End Traceability

Salesforce integrates seamlessly with ERP systems like SAP, Oracle, and Infor, along with IoT sensors and transport management systems. This integration delivers:

- Complete farm-to-retail traceability

- Automated compliance reporting

- Real-time monitoring of milk collection routes and cooling stations

With APIs and MuleSoft integration, data flows continuously — no manual intervention needed.

? Case Example: Reducing Spoilage with Salesforce Data Intelligence

Scenario (Illustrative):

A global dairy brand operating across five processing plants faced a 12% annual product loss due to cold chain gaps.

After deploying Salesforce Manufacturing Cloud integrated with IoT

temperature sensors:

- Cold chain compliance improved by 40%

- Spoilage reduced by 18% in six months

- Real-time alerts helped recover $1.2M in annual losses

- Forecast accuracy increased from 68% to 90%

The company also leveraged Salesforce dashboards to coordinate faster delivery routes and gain insight into distributor-level demand.

? KPIs to Measure Success in Perishable Supply Chains

The next generation of F&B distribution networks will be digitally connected, AI-empowered, and analytics-driven.

- Spoilage Reduction (%)

- On-Time Delivery Rate (%)

- Cold Chain Compliance (%)

- Inventory Turnover Ratio

- Forecast Accuracy (%)

- Distributor Order Fill Rate (%)

- Transportation Efficiency (Lead Time)

? The Future of Data-Driven Cold Chain Management

The next era of dairy logistics will be defined by predictive, sensor-driven supply chains.

Technologies like AI forecasting, blockchain traceability, and connected IoT ecosystems are converging — and Salesforce sits at the center.

Future-ready dairy manufacturers will:

- Integrate IoT sensors directly into Salesforce workflows

- Use AI to predict spoilage risk before it occurs

- Enable blockchain-backed farm-to-consumer transparency

With Salesforce Manufacturing Cloud, data is no longer reactive — it’s predictive and proactive.

? Why Partner with Perigeon Software

As a trusted Salesforce Consulting Partner, Perigeon Software helps dairy and food manufacturers:

- Implement Salesforce Manufacturing Cloud for perishable operations

- Integrate ERP, IoT, and logistics systems for unified data visibility

- Configure AI-based dashboards to monitor temperature, transport, and supply chain KPIs

- Build actionable insights that reduce spoilage and improve margins

With industry-specific Salesforce expertise, Perigeon delivers solutions that make dairy supply chains fresher, smarter, and more profitable.

Conclusion

In the dairy industry, time is literally money — and freshness defines brand trust.

By leveraging Salesforce Manufacturing Cloud, dairy manufacturers can transform their perishable supply chains from fragmented and reactive to connected, intelligent, and predictive.

Real-time visibility, AI forecasting, and IoT integration ensure that every liter of milk and every batch of yogurt reaches consumers at peak quality — efficiently and profitably.

Perigeon Software is your partner in achieving that transformation.