Table of content

Introduction

The Cement & Building Materials Industry Landscape

Why Demand Forecasting Is Mission-Critical in Cement Manufacturing

Key Demand Forecasting Challenges in Cement & Building Materials

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

Case Study: Cement Manufacturer Improves Forecast Accuracy with Salesforce

The Future of Demand Forecasting in Cement & Building Materials

Conclusion

1.Introduction

Cement and building materials manufacturing sits at the core of global infrastructure development. Roads, bridges, housing, commercial real estate, and industrial facilities all depend on reliable cement, concrete, aggregates, and allied materials.

However, forecasting demand in this industry is uniquely complex.

Consumption is driven by:

- Infrastructure budgets

- Real estate cycles

- Government policy

- Regional construction activity

According to McKinsey (2024), cement manufacturers face demand forecast deviations of 20–30%, leading to idle capacity, logistics bottlenecks, or missed high-margin opportunities during peak construction seasons.

Salesforce Manufacturing Cloud enables cement and building materials manufacturers to improve forecast accuracy by aligning sales agreements, distributor demand, production capacity, and AI-driven insights into a single planning framework.

The Cement & Building Materials Industry Landscape

- Core Products: Cement, ready-mix concrete, aggregates, clinker, blocks

- Customers: Infrastructure developers, contractors, governments, real estate firms

- Sales Model: Distributor-led + project-based direct sales

- Production Model: Continuous, high-capacity plants with limited flexibility

👉 Even small forecasting errors can result in massive cost and logistics inefficiencies.

Why Demand Forecasting Is Mission-Critical in Cement Manufacturing

- Plant Utilization Optimization → Kilns and grinding units must run near optimal load

- Logistics Planning → Cement is bulky and expensive to transport

- Regional Supply Balancing → Demand varies sharply by geography

- Margin Protection → Energy and freight costs dominate margins

- Infrastructure Commitments → Large projects require assured supply

Key Demand Forecasting Challenges in Cement & Building Materials

1. Infrastructure-Driven Demand Volatility

- Public infrastructure spending fluctuates with budgets and approvals

- Delays or accelerations disrupt demand projections

2. Regional & Project-Based Consumption Patterns

- Urban and rural markets behave very differently

- Mega-projects skew regional demand

3. Distributor-Heavy Sales Models

- OEMs rely on thousands of distributors

- Limited real-time visibility into true market demand

4. Capacity Constraints & Clinker Planning

- Kilns and clinker production cannot be adjusted instantly

- Poor forecasts lead to excess inventory or shortages

5. Limited Sales–Operations Synchronization

- Sales forecasts live in CRM or spreadsheets

- Production planning happens in ERP

- No shared ownership of forecast accuracy

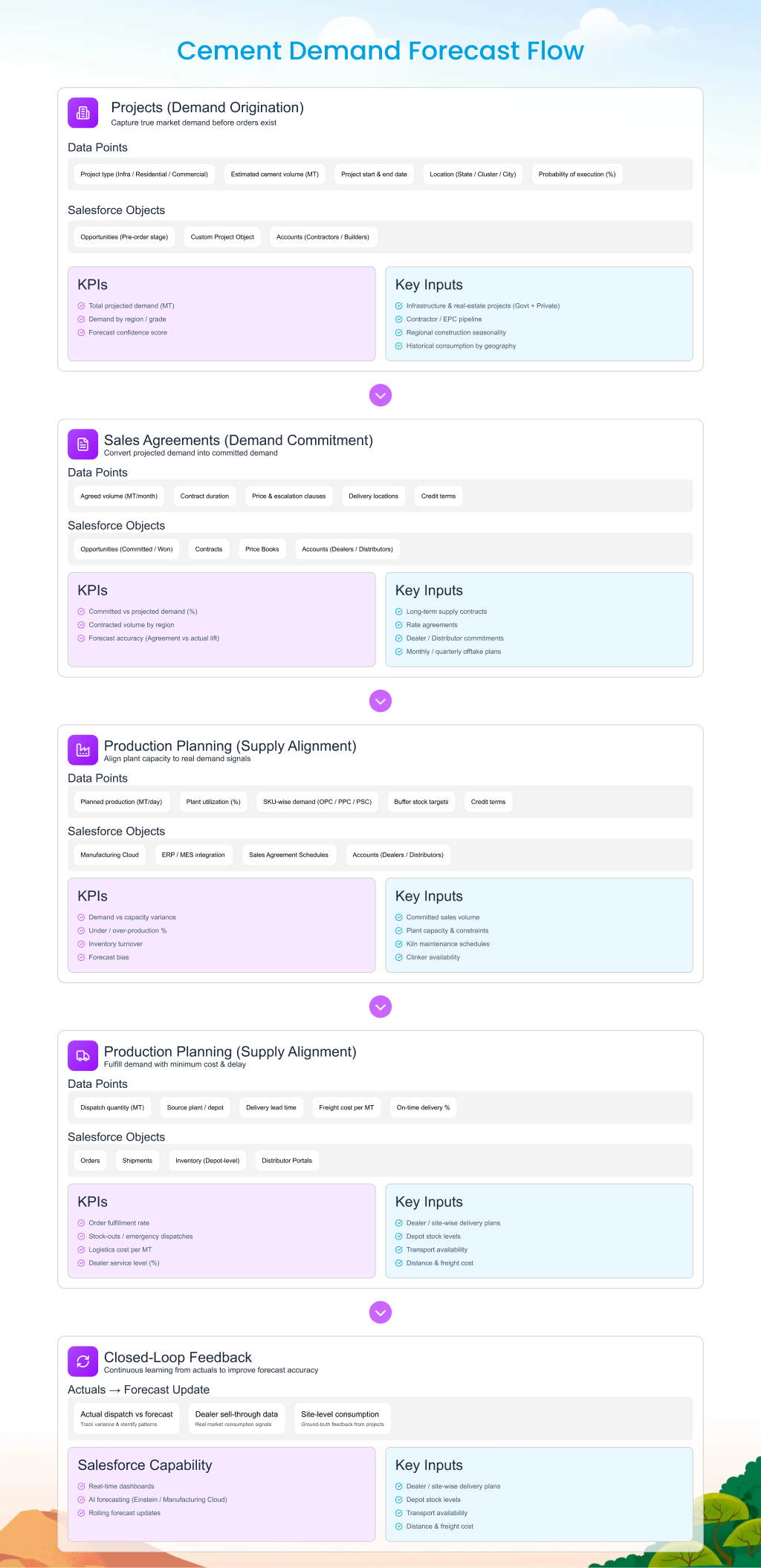

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

1. Project- & Account-Based Forecasting

- Forecasts demand by:

- Infrastructure project

- Key contractor or developer

- Region and product type

- Improves forecast accountability and precision

2. Sales Agreement–Driven Demand Commitments

- Converts long-term project contracts into committed demand signals

- Prevents overreliance on speculative forecasts

3. Distributor Demand Visibility & Collaboration

- Distributors update demand forecasts through Experience Cloud portals

- Near real-time consumption signals improve planning accuracy

4. ERP & Production Planning Integration

- Aligns Salesforce forecasts with ERP production schedules

- Enables better clinker planning and dispatch optimization

5. AI-Powered Demand Sensing & Risk Alerts

- Einstein AI analyzes:

- Historical consumption

- Infrastructure pipeline data

- Seasonal construction trends

- Flags forecast risks early

Case Study: Cement Manufacturer Improves Forecast Accuracy with Salesforce

A regional cement manufacturer supplying large infrastructure and housing projects faced:

- 28% forecast deviation

- Overstocking in low-demand zones

- Frequent emergency dispatches

After Salesforce Manufacturing Cloud implementation:

- Forecast accuracy improved by 27%

- Logistics costs reduced by 15%

- Plant utilization stabilized across quarters

The Future of Demand Forecasting in Cement & Building Materials

- AI-Driven Project Demand Modeling

- Digital Twin Plants for capacity simulation

- IoT-Enabled Dispatch Forecasting

- Carbon-Aware Production Planning aligned with ESG goals

Conclusion

Accurate demand forecasting is the foundation of profitability in cement and building materials manufacturing. Salesforce Manufacturing Cloud enables:

- Project-driven demand planning

- Distributor-aligned market visibility

- ERP-integrated production forecasting

- AI-powered early risk detection

With Salesforce, cement manufacturers move from reactive planning to predictable, cost-efficient execution.

🏗️ Ready to improve demand forecasting in cement manufacturing?

👉 Book a Manufacturing Cloud Strategy Session with Perigeon