Table of content

Introduction

Understanding the Complexity of Chemical Sales Agreements

Key Challenges in Chemical Contract Management

Why Salesforce Manufacturing Cloud Is the Right Fit

How Manufacturing Cloud Transforms Sales Agreement Management

Case Example: Streamlining Sales Agreements for a Global Chemical Producer

Tangible Business Outcomes

Future of Contract Digitization in the Chemical Industry

Why Partner with Perigeon Software

Conclusion

? Introduction

Chemical manufacturing operates in one of the most dynamic and complex business environments.

Between volatile raw material costs, changing regulatory frameworks, and multi-year contracts with industrial clients, managing sales agreements can feel like navigating a maze.

Most manufacturers still rely on manual spreadsheets, disconnected CRMs, or outdated ERPs, which limit visibility and cause revenue leakages.

That’s where Salesforce Manufacturing Cloud comes in — enabling chemical manufacturers to manage contracts, pricing, and customer relationships on a unified, transparent, and intelligent platform.

“In chemical manufacturing, a well-managed sales agreement isn’t just a document — it’s a strategic lever for profitability and customer trust.”

? Understanding the Complexity of Chemical Sales Agreements

Unlike short-cycle consumer goods, chemical industry contracts are often:

- Long-term (1–5 years or more)

- Dependent on commodity market fluctuations

- Priced based on volume, region, or customer tier

- Subject to quality and regulatory compliance clauses

A single manufacturer might manage hundreds of active agreements, each with unique pricing formulas, delivery commitments, and rebate structures.

Without automation, this leads to inefficiency, misaligned forecasts, and missed revenue recognition.

⚠️ Key Challenges in Chemical Contract Management

Chemical manufacturers face several persistent challenges in managing sales agreements effectively:

- Manual Data Handling – Agreements are tracked in static files, creating version control issues.

- Inconsistent Pricing – Price escalations based on raw material indices or FX rates are difficult to manage manually.

- Limited Visibility – Lack of real-time insights into agreement performance or fulfillment rates.

- Revenue Leakage – Delays in updating contract terms lead to pricing mismatches or missed rebates.

- Disconnected Systems – CRM, ERP, and finance systems often operate in silos.

These challenges don’t just waste time — they can lead to financial inaccuracies and reputational risks.

⚙️ Why Salesforce Manufacturing Cloud Is the Right Fit

Salesforce Manufacturing Cloud was purpose-built to handle the complexity of B2B sales agreements found in industrial sectors like chemicals and materials.

It offers a unified view of::

- Sales agreements and order volumes

- Actual vs. planned performance metrics

- Pricing structures, rebates, and renewal timelines

By bridging sales and operations data, it ensures every contract is accurate, traceable, and strategically aligned with production planning and revenue goals.

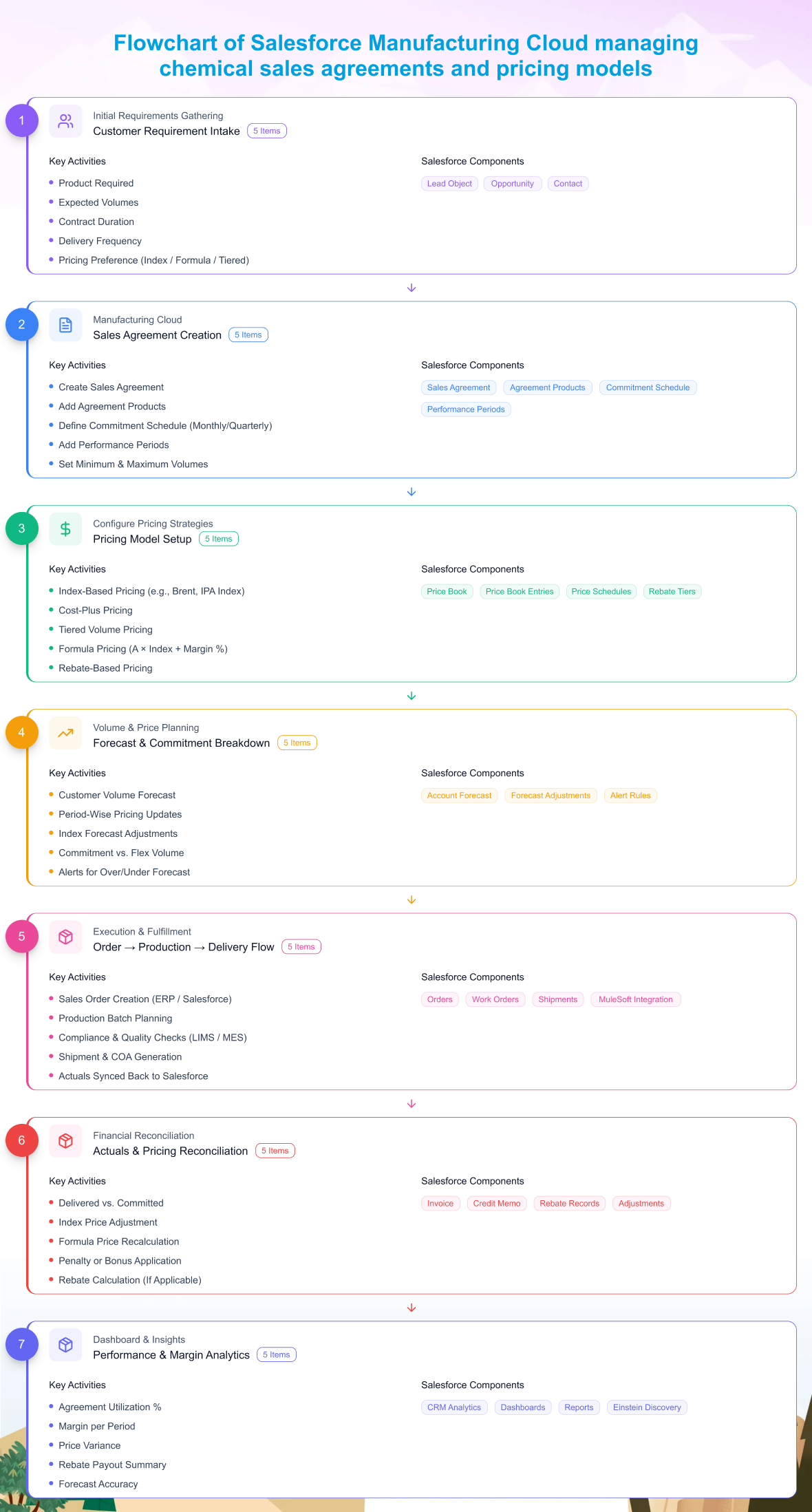

? How Manufacturing Cloud Transforms Sales Agreement Management

1️⃣ Unified Agreement Lifecycle

Manufacturing Cloud centralizes every sales agreement within a single digital repository.

Manufacturers can:

- Store agreement templates, pricing structures, and compliance terms

- Track amendments and renewals

- Automatically generate customer-specific agreements

Each update instantly syncs across sales, finance, and operations — ensuring everyone works from the same version of truth.

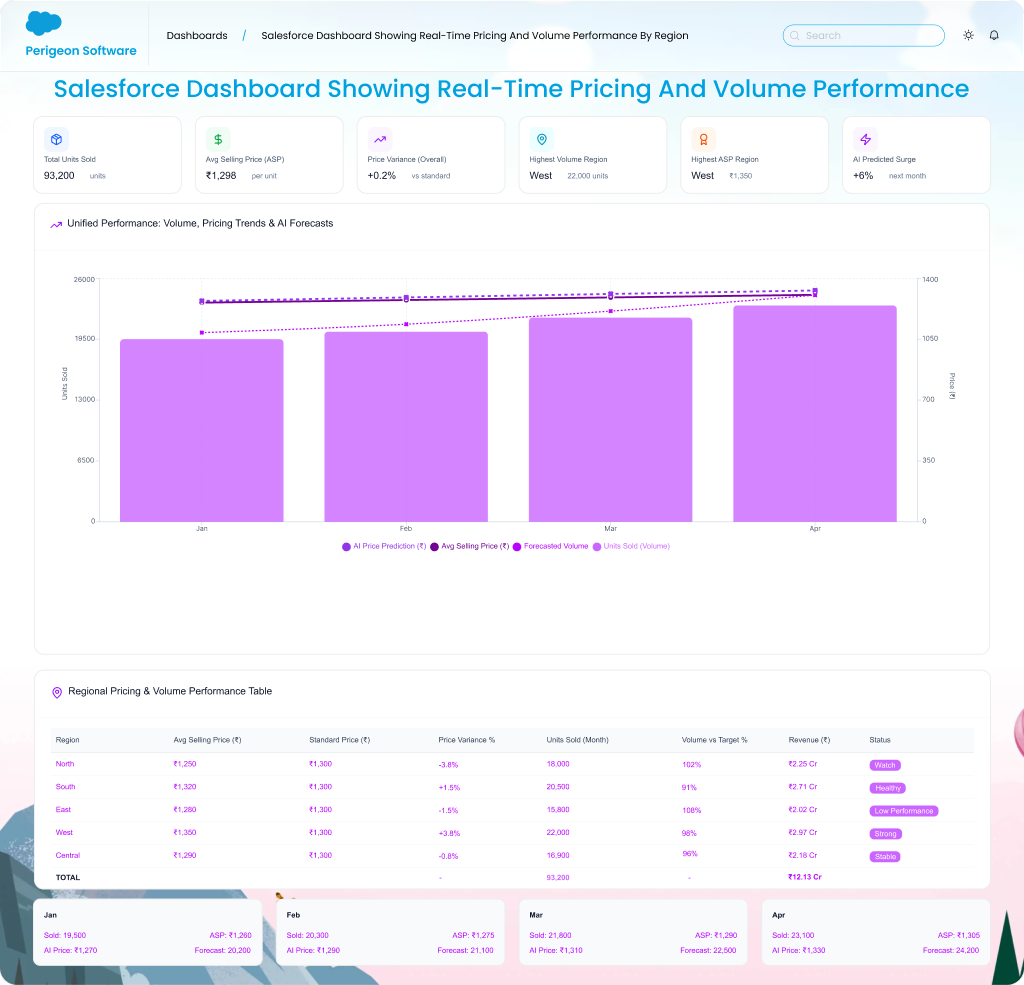

2️⃣ Real-Time Pricing & Volume Tracking

Dynamic pricing in chemicals depends on raw material indexes, transportation costs, and customer categories.

With Salesforce, pricing rules can be automated and linked to:

- Market indices (e.g., crude oil, natural gas, resin costs)

- Regional delivery expenses

- Contractual escalation clauses

This ensures accurate invoicing and transparency — reducing pricing disputes with customers and distributors.

3️⃣ Automated Renewals & Adjustments

Manufacturing Cloud automates the renewal process by alerting teams when agreements approach expiry or volume thresholds.

- Renewal reminders and approval workflows ensure timely renegotiations.

- Price updates based on market shifts can be auto-applied using predefined rules.

- Volume commitments can be tracked and adjusted dynamically.

This proactive management keeps contracts profitable and compliant.

4️⃣ Integrated Demand Forecasting

Sales agreements in Manufacturing Cloud directly feed into Salesforce Einstein Analytics, which analyzes consumption trends and predicts future demand.

For example:

- If a customer’s usage pattern increases, planners can adjust production forecasts.

- Sales teams can proactively propose new volume tiers or product bundles.

This integration bridges sales and operations — aligning forecasts with actual agreement performance.

5️⃣ Transparent Performance Analytics

Manufacturers can use customizable dashboards to track:

- Actual vs. committed volumes

- Profitability per contract

- Renewal rates and pricing variances

- Customer satisfaction metrics

With visibility across all agreements, leadership can make data-driven decisions and identify underperforming contracts early.

? Case Example: Streamlining Sales Agreements for a Global Chemical Producer

Scenario:

A multinational chemical manufacturer managing 300+ customer contracts struggled with inconsistent pricing and slow renewals.

Challenges:

- Manual tracking in spreadsheets

- Price discrepancies due to fluctuating feedstock costs

- Delayed reporting for finance and operations

Solution Implemented by Perigeon Software:

- Salesforce Manufacturing Cloud deployment integrated with ERP and CPQ systems

- Automated pricing logic tied to market indices

- Digital dashboards for agreement lifecycle management

Results:

- 40% faster contract renewal cycles

- 30% reduction in pricing errors

- 25% improvement in revenue predictability

- Full audit trail compliance across all agreements

? Tangible Business Outcomes

Organizations that digitize sales agreement management with Manufacturing Cloud typically achieve:

- 35–40% faster contract-to-cash cycles

- 20–25% reduction in manual data entry errors

- 15–20% improvement in forecast accuracy

- Complete visibility into contract performance across customers

The result? Higher profitability, stronger compliance, and trusted customer relationships.

? The Future of Contract Digitization in the Chemical Industry

The chemical industry is shifting toward data-driven, AI-assisted contract management.

Future trends include:

- Predictive contract performance analytics

- AI-based negotiation assistance for renewals

- Smart contracts using blockchain for transparency and traceability

- Integration with ESG metrics for sustainable manufacturing commitments

Salesforce’s open and scalable platform ensures manufacturers can evolve seamlessly into these next-generation capabilities.

? Why Partner with Perigeon Software

As a trusted Salesforce Consulting Partner, Perigeon Software specializes in transforming chemical and materials manufacturers with:

- Salesforce Manufacturing Cloud implementation

- Custom sales agreement workflows & approval hierarchies

- ERP & pricing engine integrations

- Compliance reporting and analytics dashboards

- Ongoing optimization through AI and automation

We help chemical enterprises digitize their sales processes and achieve full visibility — from contract creation to execution.

? Conclusion

Managing sales agreements effectively is the foundation of success in chemical manufacturing.

With Salesforce Manufacturing Cloud, companies can automate, track, and optimize every agreement — ensuring compliance, accuracy, and profitability.

Partnering with Perigeon Software means transforming your contract management from reactive to predictive — gaining control, visibility, and a strategic edge in a competitive industry.