Table of content

Introduction

The Forecasting Challenge in Industrial Plastics Manufacturing

Why Traditional Forecasting Models Fall Short

Salesforce Manufacturing Cloud: The Foundation of Smarter Forecasting

How Salesforce Transforms Forecasting Accuracy in Plastics

Real-World Example: Improving Forecast Accuracy for a Polymer Manufacturer

Key Business Outcomes of Better Forecasting

Why Partner with Perigeon Software

Conclusion

? Introduction

In the world of industrial plastics manufacturing, precision and predictability are vital.

Manufacturers supplying polymers, films, or injection-molded components must balance fluctuating raw material costs, volatile customer demand, and tight production schedules — all while maintaining profitability.

Yet, demand forecasting often remains fragmented. Sales teams work on spreadsheets, production relies on outdated ERP data, and distributors operate in silos.

Enter Salesforce Manufacturing Cloud — a unified platform that enables manufacturers to integrate sales data, customer commitments, and operational forecasts into a single source of truth.

With Salesforce, plastics manufacturers can streamline demand forecasting, respond faster to market changes, and optimize production planning with precision.

? The Forecasting Challenge in Industrial Plastics Manufacturing

Industrial plastics manufacturers operate in an ecosystem where small changes can create massive impact.

Key factors complicating forecasting include:

- Volatile raw material prices (resins, polymers, additives)

- Unpredictable OEM demand in sectors like automotive or electronics

- Lengthy lead times between order and production

- Complex contract agreements tied to volume commitments

A misaligned forecast can cause:

- Overstock of expensive raw materials

- Underproduction during peak demand

- Missed contractual obligations and revenue losses

According to PwC Manufacturing Insights (2024), 61% of plastics producers report “limited visibility between sales and production forecasts” as their top operational bottleneck.

⚠️ Why Traditional Forecasting Models Fall Short

Despite massive digital investments, many plastics manufacturers still rely on:

- Spreadsheets and disconnected CRMs

- Static forecasts updated quarterly

- Separate systems for sales, production, and supply chain

These limitations lead to:

- Siloed visibility — teams can’t see real-time forecast updates.

- Reactive adjustments — demand changes are caught too late.

- Manual errors — data inconsistencies lead to wrong projections.

- Inaccurate customer-level forecasting — no linkage between account agreements and actual consumption.

To stay competitive, manufacturers need real-time, data-driven forecasting that integrates with their full operational workflow.

⚙️ Salesforce Manufacturing Cloud: The Foundation of Smarter Forecasting

Salesforce Manufacturing Cloud unites customer data, sales agreements, and operational insights into one unified forecasting engine.

It provides real-time collaboration between sales, operations, and supply chain teams — ensuring forecasts are continuously updated as markets shift.

Key Advantage:

Instead of relying on static spreadsheets, teams can visualize, adjust, and automate forecasts based on live sales data, order status, and historical trends.

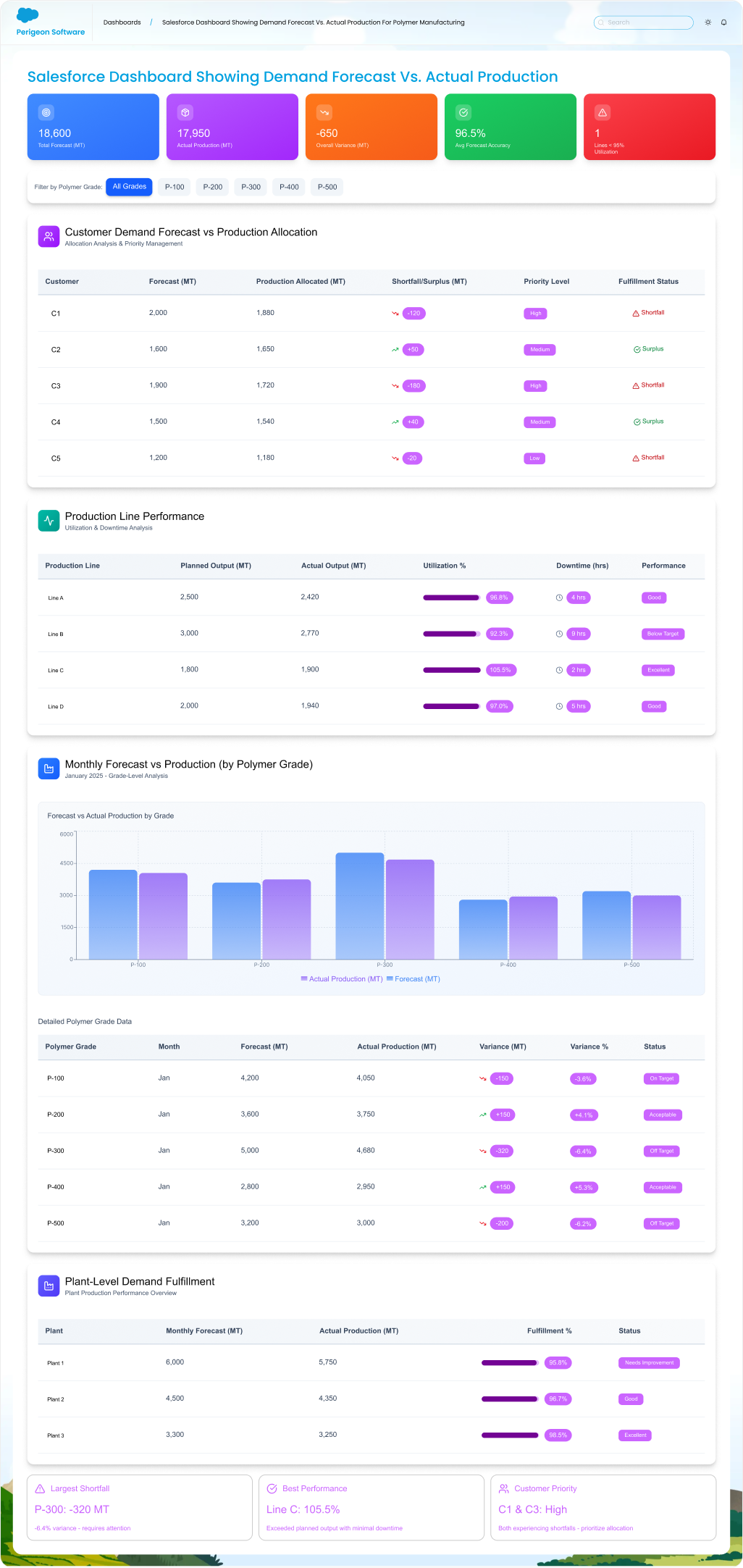

? How Salesforce Transforms Forecasting Accuracy in Plastics

1️⃣ Unified Sales & Operations Data

Manufacturing Cloud consolidates data from CRM, ERP, and production systems to offer a complete picture of customer demand.

Sales, operations, and finance teams all access the same, real-time view of:

- Account-specific commitments

- Volume-based agreements

- Forecast-to-actual variance

Outcome: Forecasts are synchronized with production and inventory planning, reducing waste and improving delivery accuracy.

Result: Faster decision-making and improved customer trust.

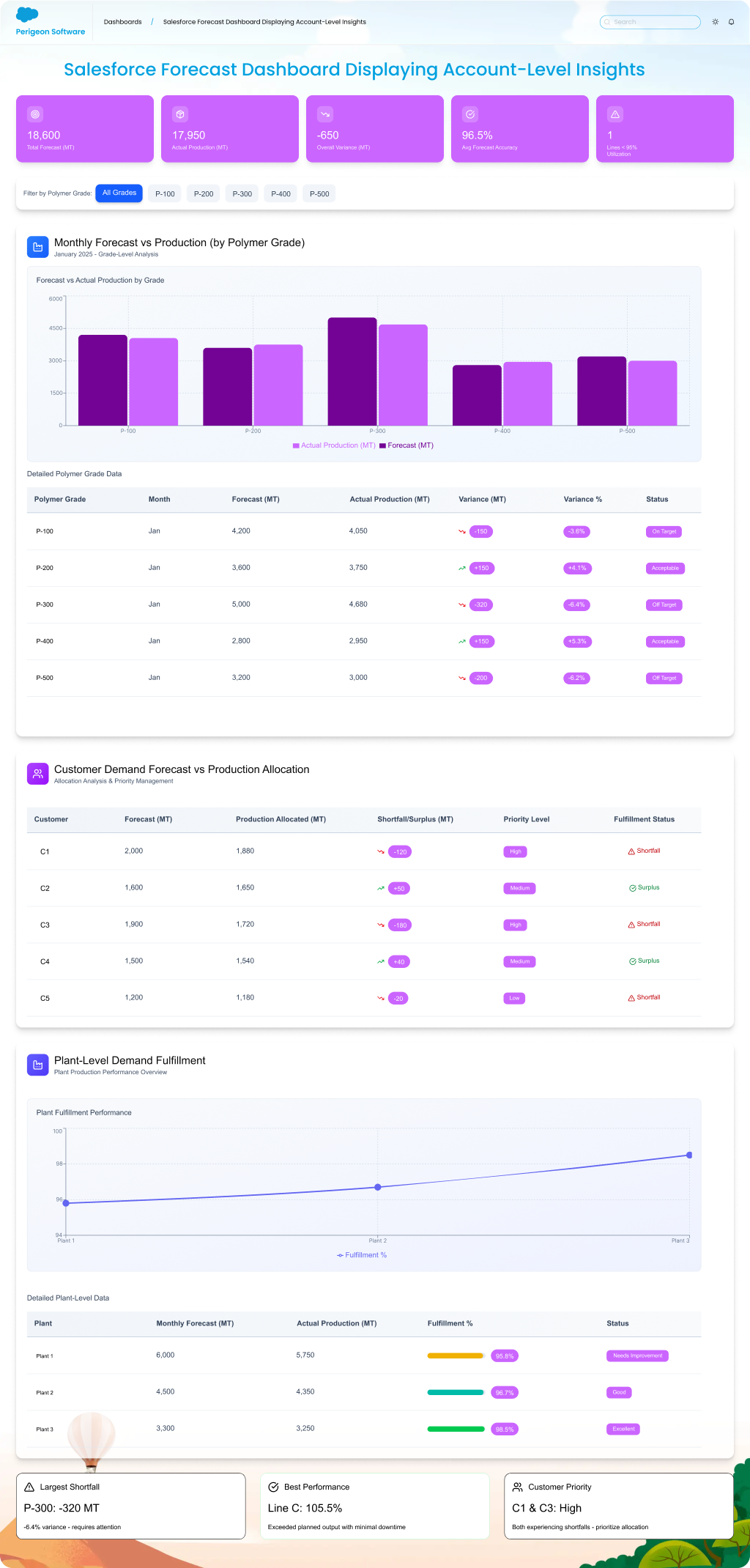

2️⃣ Account-Based Forecasting

In industrial plastics, long-term contracts with OEMs and distributors often include variable pricing and flexible volumes.

Manufacturing Cloud enables account-based forecasting, linking each forecast directly to its sales agreement.

Benefits:

- Forecast accuracy per customer or contract

- Easy adjustments for demand fluctuations

- Real-time performance monitoring vs. commitments

This approach replaces “one-size-fits-all” forecasting with precision forecasting per account — a game-changer for high-value clients.

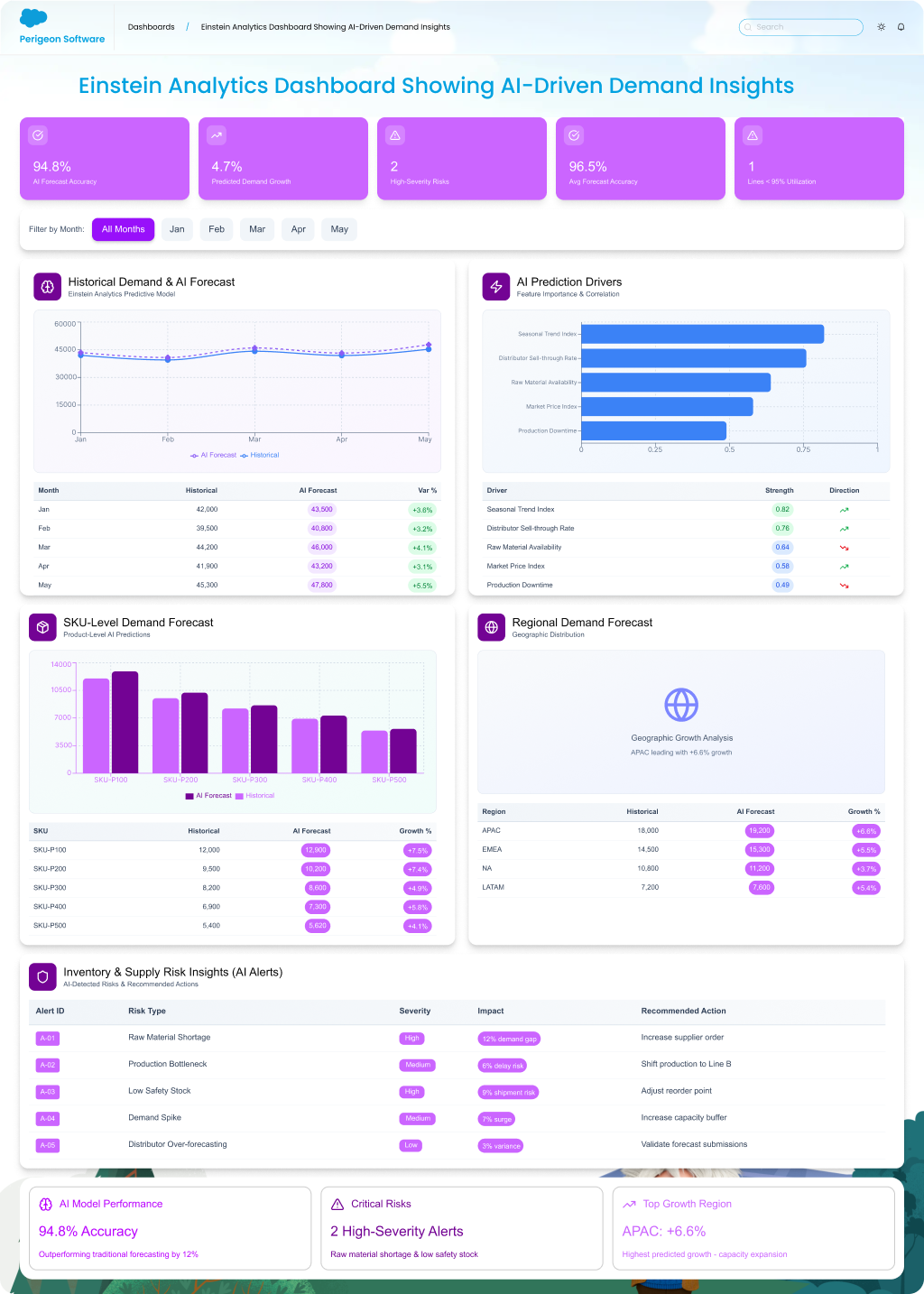

3️⃣ AI-Powered Demand Insights

With Salesforce Einstein AI, manufacturers can predict demand shifts by analyzing historical sales, seasonal patterns, and market signals.

For example, the system might detect an uptick in demand for high-strength polymers based on industry trends or historical data.

Outcomes:

- Predictive demand sensing

- Improved raw material planning

- Proactive adjustments to production scheduling

4️⃣ Collaboration Across Distributors & OEMs

Salesforce Experience Cloud allows secure, shared forecasting environments for distributors and OEM partners.

Manufacturers can:

- Collect real-time distributor forecasts

- Share updated production schedules

- Align planning cycles with major customers

Benefits:Improved coordination across the supply chain, leading to faster responses and fewer last-minute changes.

? Real-World Example: Improving Forecast Accuracy for a Polymer Manufacturer

Challenge:

A mid-sized polymer manufacturer supplying the automotive and construction sectors struggled with poor forecast visibility. Sales forecasts were often misaligned with production, leading to overstock and missed opportunities.

Solution (with Perigeon Software):

- Implemented Salesforce Manufacturing Cloud with integrated ERP data.

- Configured account-based forecasting for key OEM customers.

- Deployed Einstein Analytics for predictive demand sensing.

Results:

? Key Business Outcomes of Better Forecasting

- Higher Forecast Accuracy (up to 40%) – Real-time adjustments improve planning precision.

- Reduced Inventory Costs (20–25%) – Aligning forecasts with demand eliminates excess stock.

- Improved On-Time Delivery (15–20%) – Accurate forecasts optimize production scheduling.

- Faster Response to Market Changes – Predictive insights drive agile decision-making.

- Stronger Customer Relationships – Account-level transparency enhances trust with OEMs.

According to Salesforce Manufacturing Cloud customers, forecasting accuracy improvements can lead to 8–12% EBITDA growth annually through reduced waste and better resource allocation.

? Why Partner with Perigeon Software

Perigeon Software specializes in implementing Salesforce Manufacturing Cloud for industrial manufacturers — helping clients unlock predictive forecasting and operational visibility.

Our services include:

- Manufacturing Cloud implementation & customization

- ERP and CRM data integration

- AI-driven forecasting dashboards

- Partner collaboration portals (via Experience Cloud)

- Forecast accuracy analytics & reporting

We help transform forecasting from a reactive process into a strategic growth capability.

? Conclusion

For industrial plastics manufacturers, the future belongs to those who can predict accurately and respond instantly.

With Salesforce Manufacturing Cloud, forecasting becomes data-driven, collaborative, and adaptive — enabling smarter production planning, optimized resource allocation, and improved profitability.

Perigeon Software, as your Salesforce partner, ensures this transformation is seamless, scalable, and tailored to your manufacturing ecosystem.

Together, we turn forecasting into foresight.