Battle Motors

Digital Transformation for an Electric Commercial Vehicle OEM

Accelerating EV Innovation through Embedded & Mobile App Development

Client Overview

A North American electric vehicle (EV) manufacturer is leading the charge in transforming the commercial trucking industry with smart, sustainable transport solutions. The company specializes in heavy-duty electric trucks, and aims to enhance the driver experience, manufacturing oversight, and fleet visibility through technology-driven platforms.

To accelerate their digital product roadmap, the client partnered with Perigeon Software for product outsourcing across AOSP-based development, instrument cluster interfaces, and customer-facing applications.

Project Objectives

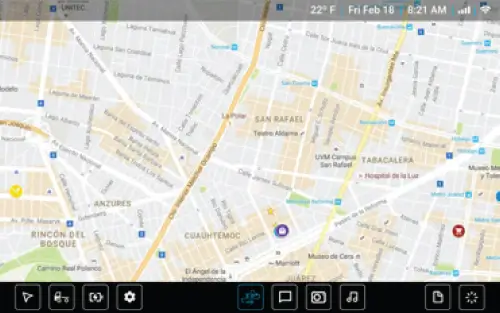

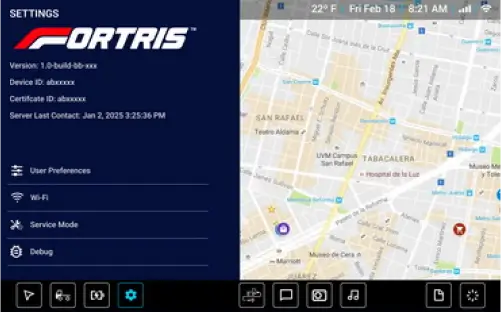

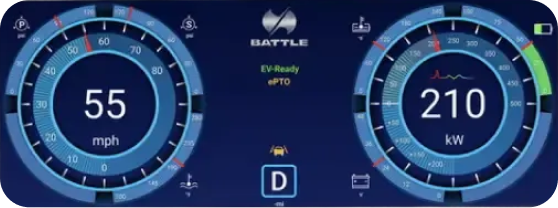

- Develop a custom instrument cluster interface for EV trucks using AOSP (Android Open Source Project)

- Build real-time assembly line tracking tools for operational efficiency

- Design and deploy a customer dashboard for vehicle insights, diagnostics, and telemetry

- Deliver a cross-platform mobile app for fleet and driver engagement

- Outsource all product development with a focus on embedded systems and mobile usability

Key Challenges

Challenge

Embedded Android Expertise

Real-Time Data Handling

Cross-Team Coordination

Multi-App Ecosystem

Hardware Constraints

Perigeon's Role as Product Outsourcing Partner

Technology Stack

- AOSP Customization: Android 11 with custom system services and UI

- Mobile App: Flutter for Android/iOS driver companion application

- Backend APIs: .NET Core + MQTT for real-time data ingestion

- Data Layer: Azure IoT Hub, SQL Server, Redis Cache

- Factory Interface: Angular 15 dashboard for assembly line data visualization

Key Products Delivered

- Instrument Cluster UI: Digital speedometer, battery health, regenerative braking, GPS

- Assembly Line Dashboard: Real-time vehicle build status, station-level telemetry

- Customer Portal: Fleet health analytics, trip history, and charging metrics

- Driver Mobile App: Vehicle diagnostics, trip logs, and real-time support chat

- OTA-ready architecture for seamless software updates

Results & Business Impact

End-to-End Digital Ecosystem

Faster Go-to-Market

Launched the first version of the cluster UI and mobile app in just 10 weeks.

Improved Driver Experience

Pilot fleet reported high satisfaction with the live cluster UI and app interface.

Enhanced Production Visibility

Scalable Architecture

Let’s Turn Complex Challenges into Seamless Experiences.

Digital Transformation for an Electric Commercial Vehicle OEM

Client Overview

Objectives & Challenges

Project Objectives

- AOSP Instrument Cluster: Build a custom digital cluster with speed, battery, GPS & regen-brake indicators.

- Manufacturing Dashboards: Enable real-time assembly line tracking and station-level visibility.

- Customer Fleet Portal: Provide fleet health, trip data, telemetry, and analytics.

- Driver Mobile App: Deliver diagnostics, trip logs, and support via a cross-platform app.

- Full Product Outsourcing: End-to-end delivery across embedded, mobile, and cloud systems.

Key Challenges

- AOSP Customization: Deep OS-level changes for in-vehicle hardware.

- Low-Latency Data: Handle telemetry and diagnostics in real time.

- Cross-Team Alignment: Sync development with manufacturing & engineering teams.

- Multi-App Consistency: Maintain unified UX across cluster, dashboards, and portals.

- Hardware Limitations: Optimize performance for constrained embedded devices.

Perigeon’s Role

Embedded

Mobile

Cloud

Technology Stack

- AOSP Customization: Android 11 with custom system services and UI

- Mobile App: Flutter for Android/iOS driver companion application

- Backend APIs: .NET Core + MQTT for real-time data ingestion

- Data Layer: Azure IoT Hub, SQL Server, Redis Cache

- Factory Interface: Angular 15 dashboard for assembly line data visualization

Delivered Solutions

Cluster

Factory

Fleet

Key Results

Improved Fleet Intelligence

Agile Process

Sprint Planning

Iterative Development

Review & Optimization

Frequently asked questions

How does Perigeon support OEM-grade engineering?

Does Perigeon offer AOSP customization for automotive platforms?

Is the solution scalable for more plants or geographies?

Does the platform support EV-specific operations?

Can technicians use the system offline?

How does Perigeon improve compliance?

Can this solution integrate with existing ERP or CRM?

Ready to Transform Your Manufacturing Operations?

Have an Idea ?

(*) Asterisk denotes mandatory fields

Success Stories