Table of content

Introduction

The Importance of Supplier Collaboration in Auto Parts Manufacturing

Challenges in Managing Supplier Collaboration

How Salesforce Manufacturing Cloud Improves Supplier Collaboration

Case Study: Supplier Collaboration Transformation with Salesforce

The Future of Supplier Collaboration in Automotive Manufacturing

Conclusion

Introduction

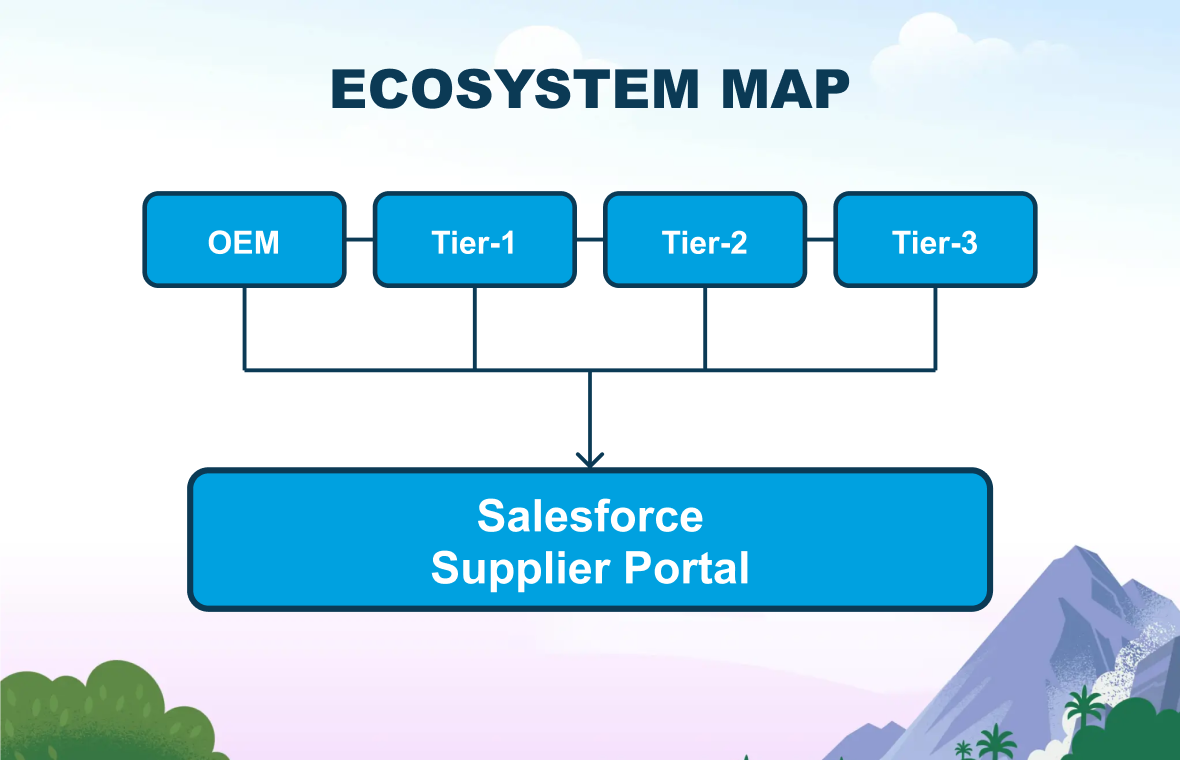

The auto parts industry is a vast ecosystem of Tier-1, Tier-2, and Tier-3 suppliers delivering everything from semiconductors to tires. For OEMs, building cars depends on thousands of suppliers delivering seamlessly. For suppliers, their success depends on alignment with OEM demand, production schedules, and rebate programs.

Yet collaboration remains one of the industry’s biggest challenges. According to a McKinsey study, 70% of supply chain disruptions in automotive come from poor supplier coordination. Disconnected systems, lack of real-time visibility, and manual communication methods create bottlenecks.

Salesforce Manufacturing Cloud solves this by providing a single source of truth for contracts, forecasts, and performance dashboards, enabling suppliers and OEMs to work together with transparency and agility.

The Importance of Supplier Collaboration in Auto Parts Manufacturing

Effective supplier collaboration enables:

- On-Time Delivery → Critical for just-in-time automotive production.

- Cost Efficiency → Reduces waste and penalty costs.

- Forecast Accuracy → Suppliers provide ground-level demand insights.

- Innovation → Collaborative suppliers help launch new technologies faster.

- Resilience → Mitigates risks during global supply chain shocks.

Without it, even the strongest OEM–supplier relationships break down, leading to delays, disputes, and profit erosion.

Challenges in Managing Supplier Collaboration

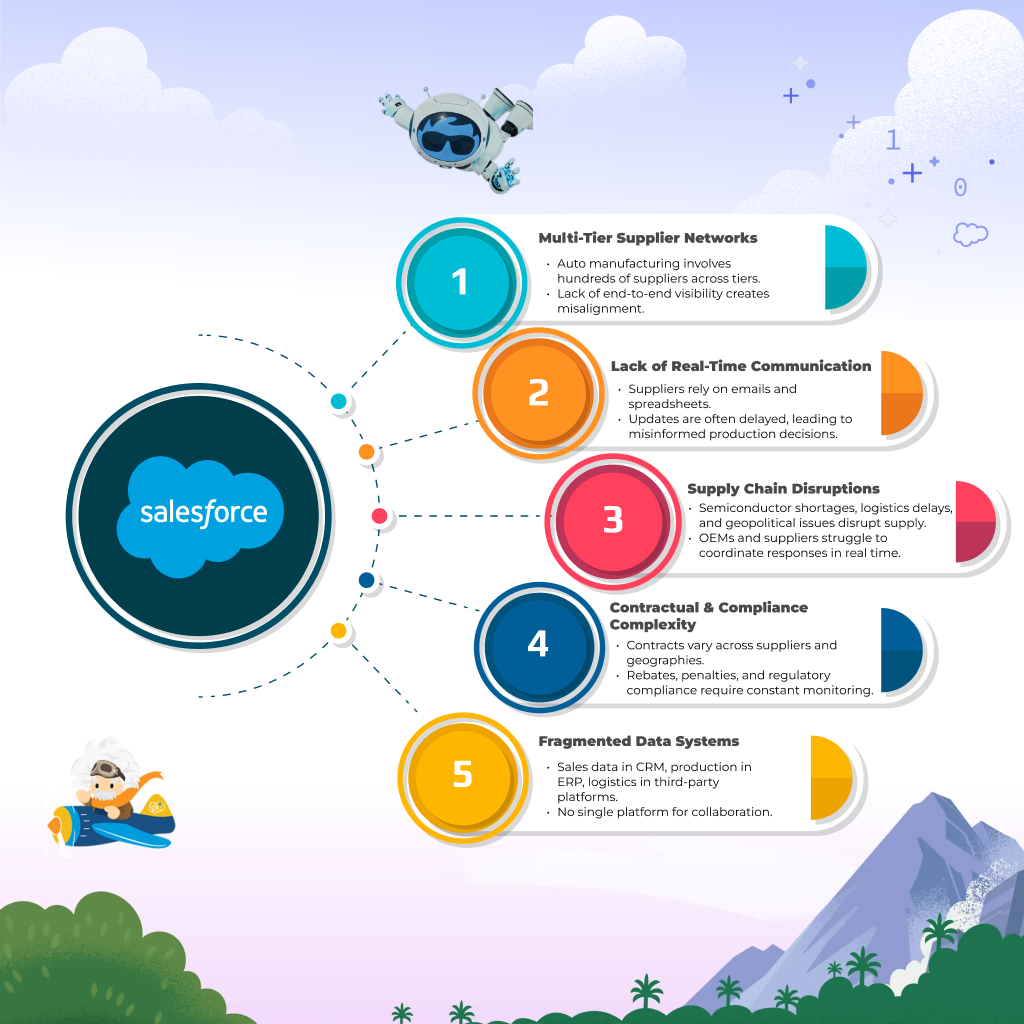

1. Multi-Tier Supplier Networks

- Auto manufacturing involves hundreds of suppliers across tiers.

- Lack of end-to-end visibility creates misalignment.

2. Lack of Real-Time Communication

- Suppliers rely on emails and spreadsheets.

- Penalty clauses apply if delivery or quality benchmarks aren’t met.

- Updates are often delayed, leading to misinformed production decisions.

3. Supply Chain Disruptions

- Semiconductor shortages, logistics delays, and geopolitical issues disrupt supply.

- OEMs and suppliers struggle to coordinate responses in real time.

4. Contractual & Compliance Complexity

- Contracts vary across suppliers and geographies.

- Rebates, penalties, and regulatory compliance require constant monitoring.

5. Fragmented Data Systems

- Sales data in CRM, production in ERP, logistics in third-party platforms.

- No single platform for collaboration.

How Salesforce Manufacturing Cloud Improves Supplier Collaboration

Salesforce Manufacturing Cloud delivers a unified, transparent, and intelligent approach to contract management for component manufacturers.

1. Unified Sales Agreements Across the Supply Chain

- Store all supplier contracts and OEM agreements in Salesforce.

- Provide shared visibility across suppliers, OEMs, and dealers.

- Ensures alignment on commitments, terms, and milestones.

👉 Example: A Tier-1 supplier managing multiple OEM contracts can track commitment vs. delivery performance in real time.

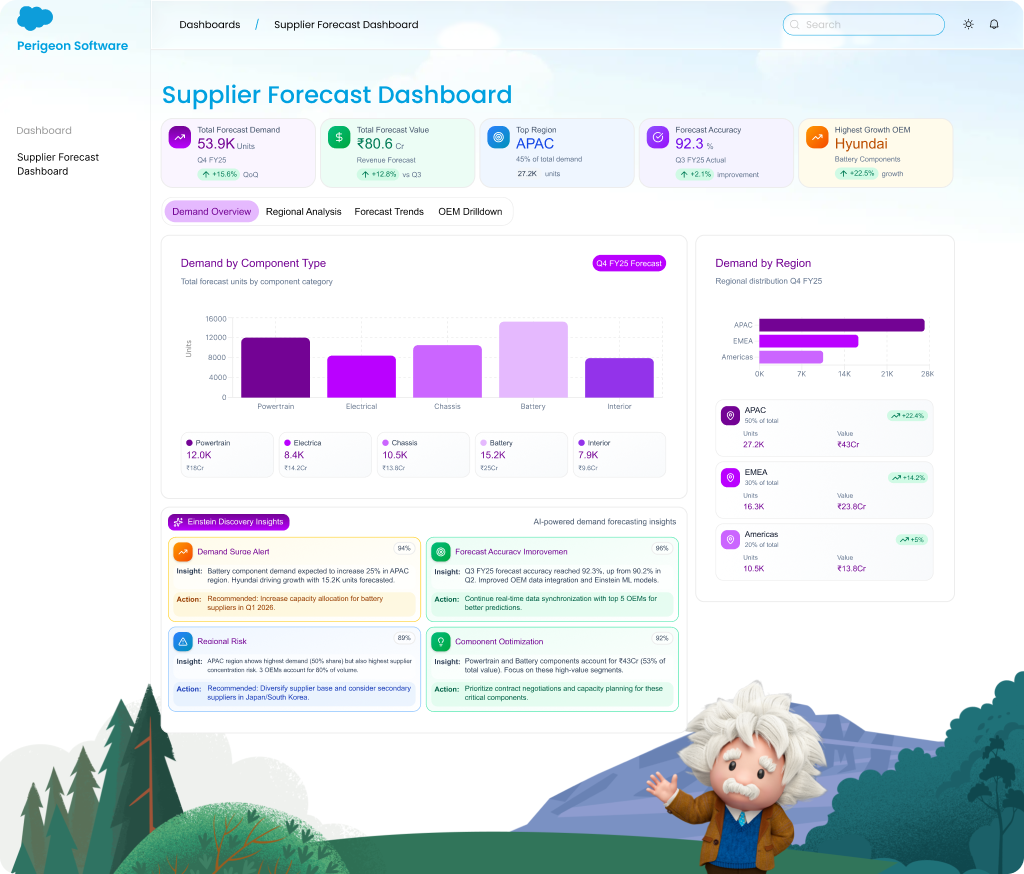

2. Real-Time Demand & Forecast Sharing

- Account-level forecasting ensures suppliers see precise OEM demand signals.

- Updates dynamically as market trends shift (e.g., EV adoption spikes).

- Improves supply planning accuracy by 20–25%.

3. Supplier Portals for Transparency & Self-Service

- Powered by Salesforce Experience Cloud.

- Suppliers can:

- View OEM commitments & forecasts

- Track contract performance

- Monitor rebate progress

- Update delivery schedules

- Eliminates dependency on manual OEM communication.

4. Automated Rebate & Incentive Programs

- Manages tiered rebate programs across suppliers automatically.

- Tracks performance and eligibility in real time.

- Reduces payment disputes and reconciliation delays.

👉 Statistic: Deloitte notes that supplier rebate disputes account for up to 12% of revenue leakage in the auto parts industry.

5. Integration with ERP & Logistics Systems

- Connects Salesforce with ERP systems (SAP, Oracle, SYSPRO).

- Integrates with logistics providers for real-time shipping visibility.

- Provides a single dashboard for end-to-end supply chain management.

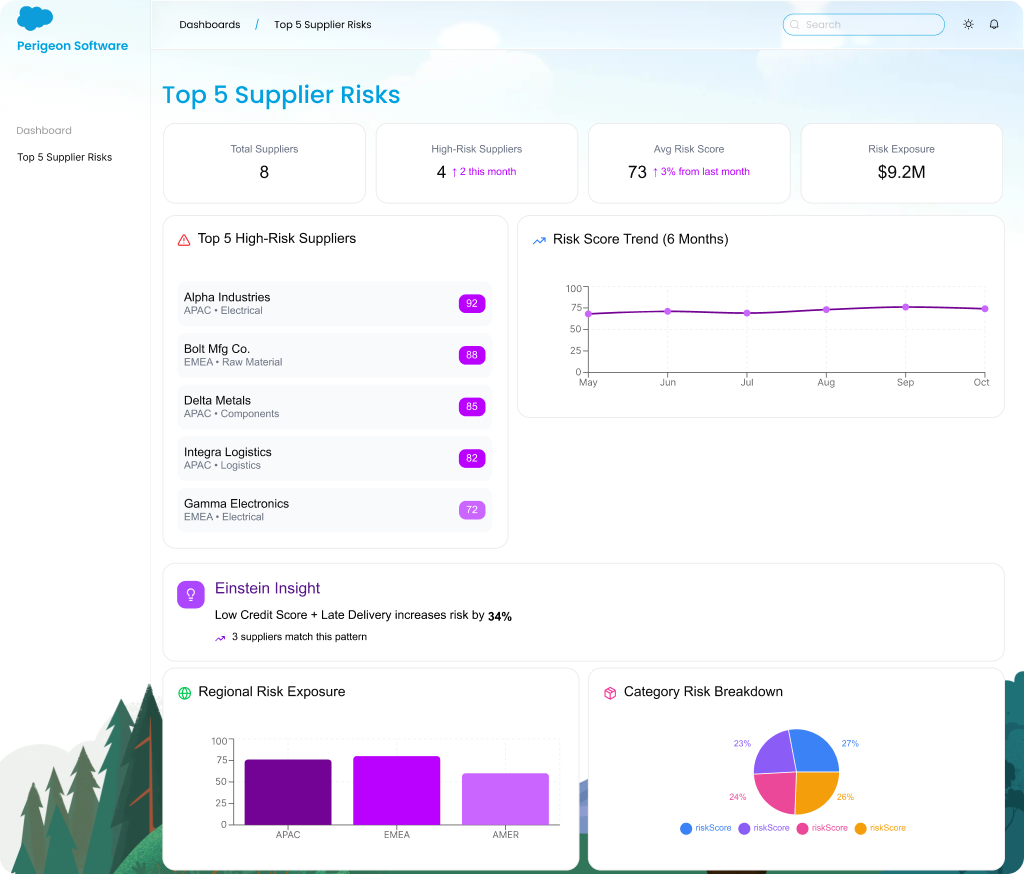

6. AI-Powered Risk & Performance Insights

- Einstein AI predicts:

- At-risk suppliers

- Delivery delays

- Capacity bottlenecks

- Provides proactive recommendations for OEMs and suppliers to mitigate risks.

👉 Example: If AI detects potential delays in semiconductor supply, OEMs can adjust production schedules in advance.

Case Study: Supplier Collaboration Transformation with Salesforce

A Tier-1 electronics supplier faced:

-

- Frequent delivery delays from Tier-2 suppliers.

- Disputes with OEMs over rebate eligibility.

After adopting Salesforce Manufacturing Cloud:

- Supplier collaboration improved with real-time portals.

- Forecast accuracy rose by 22%.

- Rebate disputes dropped by 60%, improving OEM–supplier trust.

The Future of Supplier Collaboration in Automotive Manufacturing

The future of supplier collaboration will be shaped by:

- Blockchain Contracts → Ensuring tamper-proof, transparent supplier agreements.

- IoT-Enabled Supply Chains → Connected sensors providing live updates on shipments.

- AI-Driven Ecosystem Forecasting → Predicting multi-tier supplier risks.

- Sustainability Metrics → Embedding ESG compliance in supplier collaboration.

According to PwC, digital supply chain collaboration could reduce costs by 15% and improve resilience dramatically.

Conclusion

Supplier collaboration is no longer a back-office process — it is a strategic differentiator in the auto parts industry. Salesforce Manufacturing Cloud empowers manufacturers to:

- Unify contracts and agreements across OEMs and suppliers.

- Share real-time forecasts with accuracy and agility.

- Enable supplier transparency via self-service portals.

- Automate rebates and incentives, reducing disputes.

- Leverage AI insights to predict risks and strengthen supply chains.

For auto parts manufacturers under pressure from OEMs, regulations, and global disruptions, Salesforce provides the platform for resilient, transparent, and profitable supplier collaboration.

🔩 Ready to streamline supplier collaboration in your auto parts business?

👉 [Book a Manufacturing Cloud Strategy Session with Perigeon]