Table of content

Introduction

The Shipbuilding & Marine Manufacturing Landscape

Why Sales & Production Alignment Matters in Shipbuilding

Key Challenges in Aligning Sales & Production

How Salesforce Manufacturing Cloud Aligns Sales & Production

Case Study: Improving Sales–Production Alignment in Shipbuilding

The Future of Sales–Production Integration in Marine Manufacturing

Conclusion

Introduction

Shipbuilding is one of the most capital-intensive and complex industries in manufacturing. Whether building naval ships, cargo vessels, or luxury yachts, projects often span 3–7 years and involve thousands of suppliers, engineers, and contractors.

The challenge? Aligning sales agreements with production schedules. Missed timelines lead to multi-million dollar penalties, while poor forecasting ties up billions in capital.

A McKinsey report (2024) revealed that over 60% of shipbuilding projects run behind schedule due to poor sales–production alignment.

Salesforce Manufacturing Cloud provides the platform to align sales and production with precision. By digitizing contracts, improving forecasting, and integrating with ERP and yard systems, it ensures predictable delivery and profitability.

The Shipbuilding & Marine Manufacturing Landscape

- Global Industry Size: ~$150B annually (Statista, 2025).

- Segments: Commercial (cargo, cruise ships), Defense (naval vessels), and Recreational (yachts).

- Complexity: Thousands of components, long lead times, and strict compliance (IMO, DoD, classification societies).

👉 Successful shipbuilding requires tight synchronization between sales contracts, production yards, and suppliers.

Why Sales & Production Alignment Matters in Shipbuilding

- Revenue Predictability → Long-term contracts drive stable revenue if aligned with production.

- On-Time Delivery → Delays damage client trust and attract penalties.

- Cost Efficiency → Overproduction or idle resources drain profitability.

- Supply Chain Coordination → Shipbuilding involves multi-tier global suppliers.

Without alignment, shipbuilders risk budget overruns, compliance failures, and reputational damage.

Key Challenges in Aligning Sales & Production

1. Multi-Year Build Cycles

- Contracts span years, requiring long-term planning.

- Any disruption compounds over time.

2. Demand Volatility Across Commercial & Defense Segments

- Defense orders are steady, while commercial markets fluctuate with global trade.

- Forecasting both segments simultaneously is difficult.

3. Siloed Sales, Finance & Production Data

- Sales in CRM, operations in ERP, yard scheduling in legacy systems.

- Lack of integration prevents a single version of truth.

4. Limited Visibility Across Global Suppliers

- Engines from Germany, steel from Korea, electronics from the U.S.

- Supplier delays ripple through production schedules.

5. Contractual Complexity & Change Orders

- Shipbuilding contracts often revised mid-project.

- Manual updates create confusion across departments.

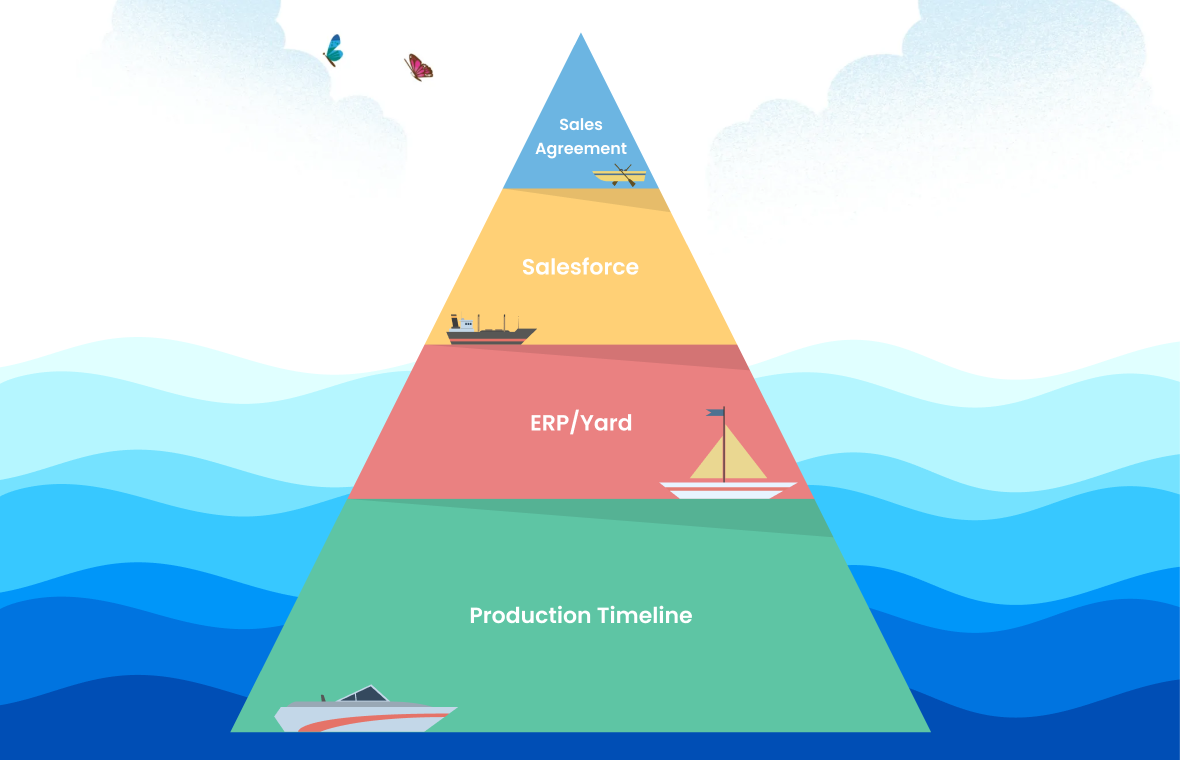

How Salesforce Manufacturing Cloud Aligns Sales & Production

1. Centralized Sales Agreements for Transparency

- Digitizes contracts and milestones in Salesforce.

- Provides shared visibility across sales, finance, and production teams.

2. Account-Based Forecasting for Marine Clients

- Forecast demand at the account or project level.

- Adjusts projections dynamically for defense vs. commercial contracts.

3. ERP & Yard Production Integration

- Connects Salesforce with ERP and yard scheduling systems.

- Ensures production schedules align with contractual milestones.

4. Real-Time Dashboards for Project Milestones

- Dashboards track:

- Contractual commitments

- Supplier deliveries

- Yard production status

- Provides single-screen visibility for executives.

5. AI-Powered Demand & Capacity Insights

- Einstein AI identifies risks in project schedules.

- Suggests proactive interventions (e.g., resource reallocation).

👉 Example: AI predicts a steel delivery delay will impact hull construction; production is rescheduled proactively.

Case Study: Improving Sales–Production Alignment in Shipbuilding

A European naval shipbuilder faced:

-

- Frequent project overruns (avg. 18 months late).

- Revenue leakage due to penalty payments.

After adopting Salesforce Manufacturing Cloud:

- Sales agreements linked directly to yard production.

- Forecast deviation reduced by 25%.

- On-time delivery rate improved by 30%.

The Future of Sales–Production Integration in Marine Manufacturing

Looking forward:

- Digital Twins for Ships → Simulate production schedules vs. contractual commitments.

- Blockchain Agreements → Transparent tracking of supplier compliance.

- AI-Powered Yard Optimization → Predict and prevent resource bottlenecks.

- Sustainability Dashboards → Tracking carbon emissions in line with IMO regulations.

Conclusion

For shipbuilders, aligning sales and production is the difference between profitable delivery and costly overruns. Salesforce Manufacturing Cloud enables:

- Centralized visibility of contracts

- Account-level forecasting for marine clients

- ERP–yard integration for seamless planning

- AI-powered insights to prevent delays

With Salesforce, shipbuilders can synchronize commitments with execution, driving predictability, trust, and competitiveness.

⚓ Ready to align your shipbuilding sales & production?

👉 [Book a Manufacturing Cloud Strategy Session with Perigeon]