Table of content

Introduction

The Railway Equipment Manufacturing Landscape

Why Operational Transformation Matters in Rail Manufacturing

Key Challenges in Rail Manufacturing Operations

How Salesforce Manufacturing Cloud Transforms Rail Manufacturing Operations

Case Study: Rail Manufacturer Transformation with Salesforce

The Future of Rail Manufacturing Operations

Conclusion

Introduction

Railway equipment manufacturing underpins the world’s transport infrastructure, producing locomotives, freight wagons, passenger coaches, and signaling systems. The industry is valued at over $200 billion globally (Markets & Markets, 2025) and is critical to both commercial trade and public transit.

But rail projects are often plagued by long production cycles, complex contracts, and multi-stakeholder coordination. A 2024 Deloitte study revealed that over 40% of rail projects run over budget due to operational inefficiencies.

Salesforce Manufacturing Cloud empowers rail equipment manufacturers to transform operations by digitizing contracts, improving forecasting, and enabling real-time collaboration across suppliers, distributors, and regulators.

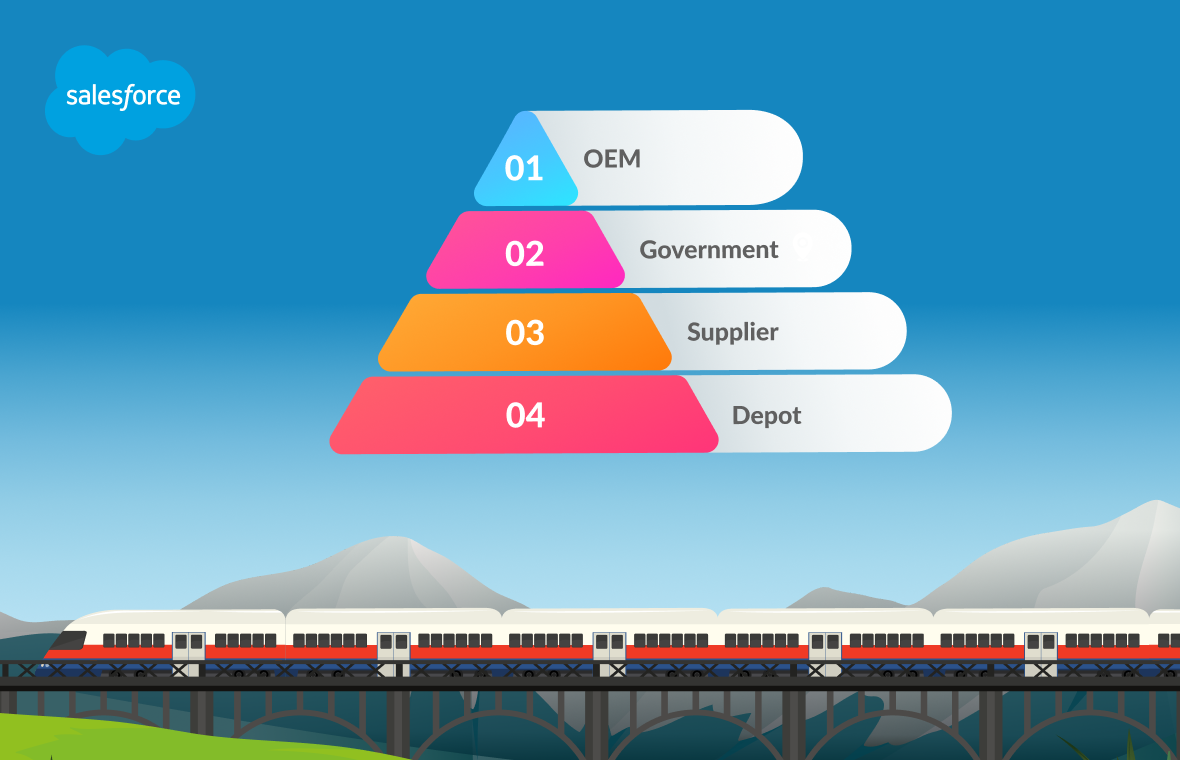

The Railway Equipment Manufacturing Landscape

- Segments: Locomotives, metro trains, high-speed rail, freight wagons, signaling & control systems.

- Clients: National governments, railway operators, infrastructure companies.

- Procurement Model: Multi-year tenders and contracts, highly regulated.

- Revenue Mix: New equipment + maintenance & service contracts.

👉 Operational success requires seamless alignment of contracts, production, and supplier collaboration.

Why Operational Transformation Matters in Rail Manufacturing

- Predictable Delivery → Delays lead to heavy penalties in government contracts.

- Efficiency → Large projects require optimized supplier and depot coordination.

- Transparency → Governments demand real-time reporting.

- Resilience → Rail supply chains are vulnerable to component shortages and political risks.

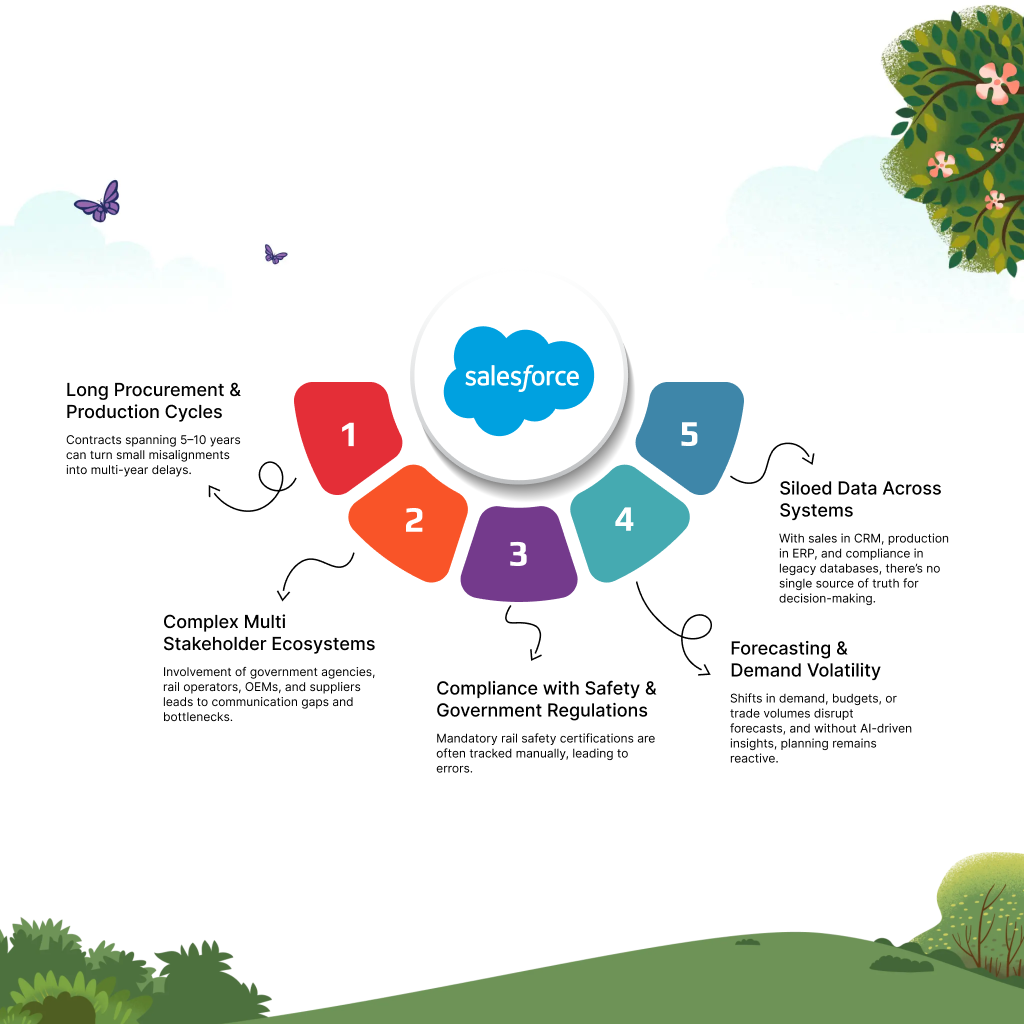

Key Challenges in Rail Manufacturing Operations

1. Long Procurement & Production Cycles

- Contracts span 5–10 years.

- Any misalignment compounds into multi-year delays.

2. Complex Multi-Stakeholder Ecosystems

- Government agencies, rail operators, OEMs, and suppliers all involved.

- Communication gaps create bottlenecks.

3. Compliance with Safety & Government Regulations

- Rail safety certifications are mandatory.

- Compliance tracking is often manual and error-prone.

4. Forecasting & Demand Volatility

- Shifts in passenger demand, infrastructure budgets, or trade volumes disrupt forecasts.

- Lack of AI-driven insights makes planning reactive.

5. Siloed Data Across Systems

- Sales in CRM, production in ERP, compliance in legacy databases.

- No single source of truth for decision-making.

How Salesforce Manufacturing Cloud Transforms Rail Manufacturing Operations

1. Centralized Sales Agreements for Operational Transparency

- Digitizes government contracts and OEM agreements.

- Links commitments to production schedules.

2. Account-Based Forecasting for Rail Projects

- Forecast demand at project/account level.

- Adjusts dynamically based on infrastructure funding changes.

3. ERP & Yard/Depot Integration

- Syncs Salesforce with ERP and depot management systems.

- Provides real-time view of progress vs. commitments.

4. Real-Time Performance Dashboards

- Tracks:

- Project milestones

- Equipment deliveries

- Supplier performance

- Enables proactive management of risks.

5. Supplier & Distributor Collaboration Portals

- Suppliers access portals for contract terms and forecasts.

- Distributors align spare part availability with OEM commitments.

6. AI-Powered Risk & Demand Insights

- Einstein AI predicts demand shifts and supply risks.

- Provides early warnings on budget changes or supplier delays.

👉 Example: AI flags that a supplier delay could jeopardize an F-35 component delivery, prompting OEM intervention.

Case Study: Rail Manufacturer Transformation with Salesforce

A European rail OEM building high-speed trains faced:

-

- Frequent delivery delays.

- Cost overruns due to poor supplier coordination.

After Salesforce:

- Forecast deviation reduced by 20%.

- On-time delivery improved by 35%.

- Regulatory audits passed with higher transparency.

The Future of Rail Manufacturing Operations

- Digital Twin Rail Projects → Simulating construction vs. demand.

- Blockchain Compliance Tracking → Immutable audit trails.

- AI-Driven Maintenance Forecasting → Predictive service planning.

- Sustainability Dashboards → Tracking carbon emissions in contracts.

Conclusion

Railway manufacturing requires precision and transparency across long, complex projects. Salesforce Manufacturing Cloud enables:

- Contract–production alignment into contracts

- Account-level forecasting

- ERP–depot integration

- AI-powered demand & risk insights

For rail manufacturers, Salesforce is the platform for operational transformation, resilience, and predictable delivery.

🚆 Ready to transform your rail manufacturing operations?

👉 [Book a Manufacturing Cloud Strategy Session with Perigeon]