Table of content

Introduction

The Mining Equipment Manufacturing Landscape

Why Forecast Optimization Matters in Mining Equipment

Challenges in Forecasting Mining Equipment Demand

How Salesforce Manufacturing Cloud Optimizes Forecasting

Case Study: Forecast Accuracy Transformation in Mining OEM

The Future of Forecasting in Mining Equipment

Conclusion

Introduction

Mining equipment manufacturing is the backbone of industrial extraction and mineral processing, producing heavy machinery like excavators, haul trucks, drills, crushers, and conveyors.

The market is projected to surpass $160 billion by 2030 (Allied Market Research, 2025) — yet OEMs face persistent challenges in forecasting demand. Commodity price swings, long equipment lifecycles, and project-based buying patterns make accurate forecasting extremely difficult.

A McKinsey study (2024) revealed that mining equipment OEMs lose 15–20% of annual efficiency due to inaccurate demand forecasting.

Salesforce Manufacturing Cloud offers a unified solution by integrating dealer inputs, AI-driven insights, and ERP data to improve forecast reliability and revenue predictability.

The Agricultural Machinery Landscape

- Segments: Tractors, harvesters, tillers, irrigation machinery, precision farming equipment.

- Sales Model: Predominantly dealer/distributor-driven.

- Customers: Farmers, co-operatives, agribusinesses, and governments.

- Revenue Mix: New equipment + service contracts, spare parts, and financing solutions.

? Sales success depends on forecast accuracy, dealer collaboration, and subsidy/financing alignment.

Why Forecast Optimization Matters in Mining Equipment

- Capital-Intensive Production → Machines cost millions; missed forecasts tie up cash flow.

- Project-Based Demand → Forecasts depend on mining exploration timelines.

- Commodity-Driven Volatility → Gold, coal, copper, and lithium prices dictate equipment orders.

- Aftermarket Growth → Predicting spare part and maintenance demand is crucial for margins.

Challenges in Forecasting Mining Equipment Demand

1. Commodity Price Volatility

- Demand tied to fluctuating commodity prices.

- Market uncertainty affects investment in new machinery.

2. Capital-Intensive, Long Sales Cycles

- Large mining contracts take 12–24 months to close.

3. Global Mining Project Dependencies

- Demand concentrated in specific regions (e.g., Australia, Chile, South Africa).

- Regional disruptions ripple globally.

4. Dealer Forecast Gaps & Regional Complexity

- Dealers lack visibility into global market trends.

- OEMs struggle to consolidate accurate global forecasts.

5. Disconnected Sales & Operations Systems

- Forecasts stored across multiple systems (CRM, ERP, dealer tools).

- No unified view for executives.

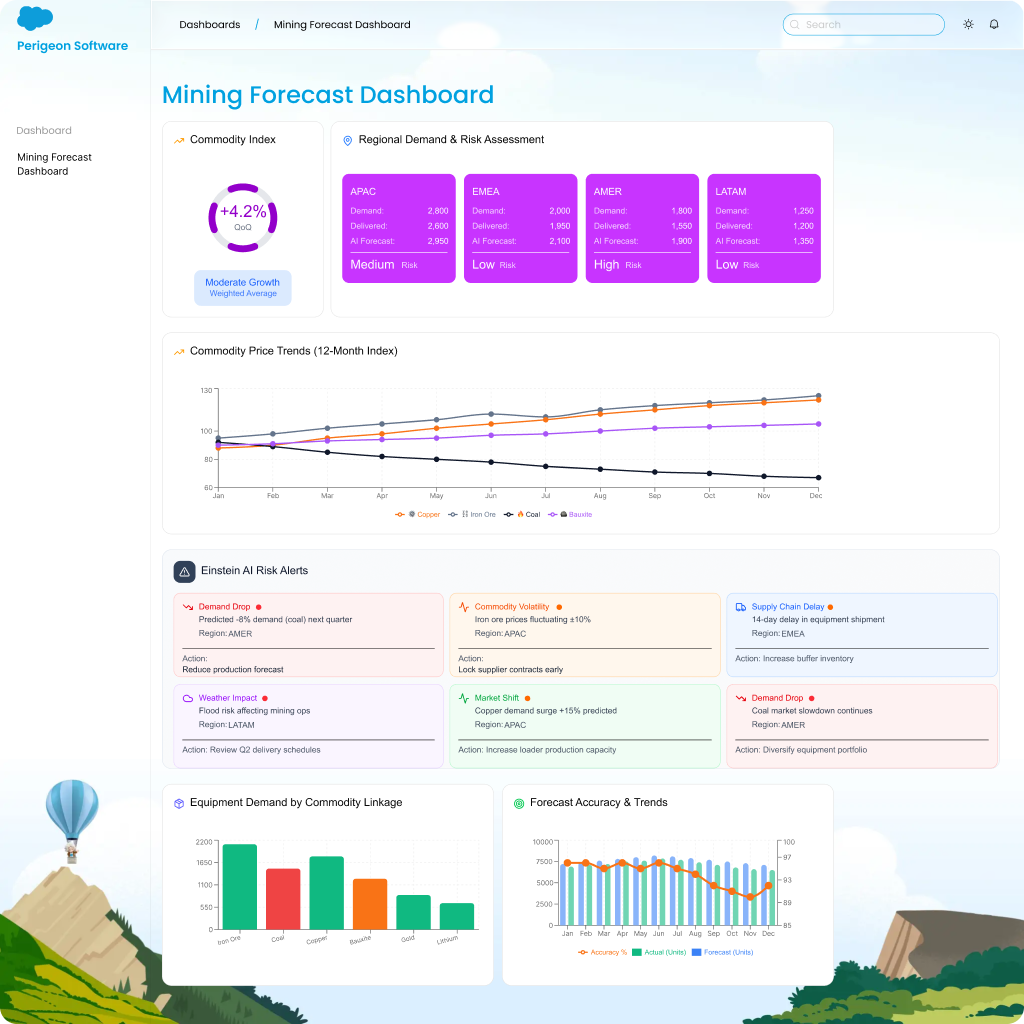

How Salesforce Manufacturing Cloud Optimizes Forecasting

1. Account-Based Forecasting for Mining Clients

- Forecasts demand at the project or client level.

- Adapts dynamically to commodity-driven cycles.

2. ERP & Supply Chain Integration

- Aligns Salesforce with ERP and supplier systems.

- Ensures production matches project schedules.

3. Real-Time Dealer & Project Visibility

- Dealers and OEMs share unified dashboards.

- Mining project changes instantly reflected in forecasts.

4. AI-Powered Demand Predictions

- Einstein AI analyzes commodity prices, exploration activity, and historical sales data.

- Predicts short-term and long-term demand trends.

5. Executive Dashboards for Transparency

- Leadership dashboards track:

- Forecast accuracy by region

- Dealer commitment vs. actuals

- Supply chain readiness

Case Study: Forecast Accuracy Transformation in Mining OEM

A mining equipment OEM serving 15 global markets faced:

-

- Forecast deviation of 25%+ annually.

- Overproduction during commodity downturns.

After Salesforce:

- Forecast accuracy improved by 28%.

- Inventory costs reduced by 18%.

- Revenue predictability improved across all major markets.

The Future of Forecasting in Mining Equipment

- AI-Commodity Correlation Models → Predicting demand based on real-time pricing.

- Blockchain Forecast Validation → Transparency between OEMs and contractors.

- Digital Twin Projects → Simulating project-level demand with live production data.

- Sustainability Forecasting → Tracking demand for low-emission mining machinery.

Conclusion

Forecasting mining equipment demand requires precision and adaptability. Salesforce Manufacturing Cloud delivers:

- Project-level forecasting accuracy

- ERP-integrated supply planning

- AI-powered demand prediction

- Dealer and project transparency

With Salesforce, mining OEMs turn market volatility into predictable growth.

⛏️ Ready to optimize your mining equipment forecasting?

? [Book a Manufacturing Cloud Strategy Session with Perigeon]