Table of content

Introduction

The Importance of Forecasting in CPG Manufacturing

Top Challenges in CPG Demand Forecasting

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

Case Study: Demand Forecast Transformation for a Beverage Brand

The Future of Forecasting in the CPG Industry

Conclusion

Introduction

Consumer Packaged Goods (CPG) manufacturing operates in one of the most volatile and fast-moving markets. Seasonal promotions, social media trends, and economic shifts all impact demand.

A PwC survey (2024) found that CPG companies face 25–35% forecast inaccuracies annually, resulting in either stockouts or excess inventory.

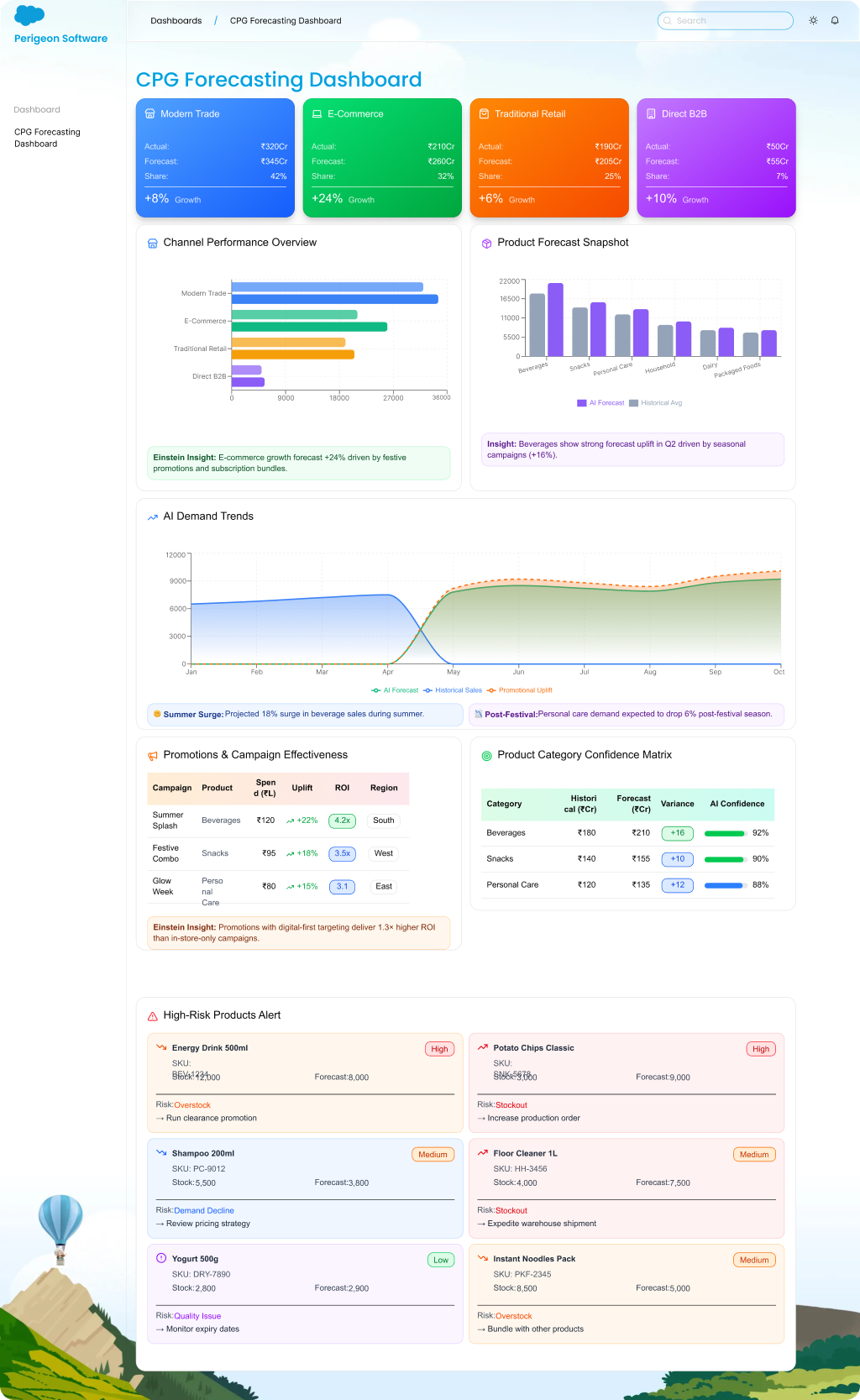

Salesforce Manufacturing Cloud addresses this by combining account-based forecasting, AI-driven insights, and real-time data synchronization, giving manufacturers the visibility and agility needed to plan effectively.

The Importance of Forecasting in CPG Manufacturing

- Efficient Production Planning → Avoid overproduction and reduce waste.

- Improved Service Levels → Ensure products are available when consumers need them.

- Financial Predictability → Stabilize cash flow and working capital.

- Sustainability → Reduce expired or unsold inventory.

Top Challenges in CPG Demand Forecasting

1. Volatile Consumer Demand

- Rapid shifts due to seasonal and cultural trends.

2. Short Product Life Cycles

- Constant launches and reformulations create unpredictability.

3. Channel Fragmentation

- Multiple channels: retail, e-commerce, and direct-to-consumer.

4. Promotion-Driven Spikes

- Trade promotions distort demand visibility.

5. Data Silos & Manual Processes

- Lack of unified data across marketing, sales, and production.

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

1. Account-Based Forecasting

- Forecasts by customer, channel, or region.

- Increases granularity and accountability.

2. Real-Time Demand Signal Integration

- AIntegrates POS and distributor data to reflect live consumption.

3. AI & Predictive Analytics for Demand Planning

- Einstein AI analyzes:

- Historical sales data

- Market sentiment

- Promotion schedules

- Predicts demand fluctuations before they occur.

4. ERP & Supply Chain Synchronization

- Connects Salesforce with ERP and logistics systems.

- Enables real-time adjustments to production schedules.

5. Performance Dashboards for Leadership

- Tracks forecast accuracy, service levels, and financial impact.

- Provides actionable insights for planners and executives.

Case Study: Demand Forecast Transformation for a Beverage Brand

A global beverage manufacturer with multi-channel operations faced:

-

- 28% forecast deviation across markets.

- Frequent underproduction during peak seasons.

After Salesforce:

- Forecast accuracy improved to 90%+.

- Wastage reduced by 15%.

- Time to respond to demand changes cut by 40%.

The Future of Forecasting in the CPG Industry

- AI-Driven Scenario Planning → Predicts impact of promotions or external events.

- IoT Data Integration → Real-time sales from connected vending machines and shelves.

- Blockchain Transparency → Verified retail and distributor data exchange.

- Sustainability Forecast Metrics → Measuring eco-efficiency in supply planning.

Conclusion

Accurate forecasting is the cornerstone of efficient, profitable CPG operations. Salesforce Manufacturing Cloud delivers:

- Account-level visibility

- AI-powered forecasting models

- Integrated ERP & supply chain planning

- Real-time retail demand synchronization

With Salesforce, CPG manufacturers achieve predictable growth, lower waste, and superior market responsiveness.

? Ready to master CPG forecasting accuracy?

? [Book a Manufacturing Cloud Strategy Session with Perigeon]