Table of content

Introduction

The Complexity of Distributor Networks in Dairy Manufacturing

Challenges in Managing Distributor Relationships

Why Collaboration Drives Profitability in Dairy Processing

How Salesforce Manufacturing Cloud Transforms Distributor Collaboration

Case Study: Improving Distributor Alignment with Salesforce

Key KPIs for Measuring Collaboration Success

The Future of Connected Dairy Ecosystems

Why Partner with Perigeon Software

Conclusion

? Introduction

Dairy manufacturing depends on one of the most distributed, fast-moving, and temperature-sensitive supply chains in the food & beverage sector. From milk processors to wholesalers and retail chains, distributors form the bridge between production and consumption.

Yet, managing this network is far from simple.

Fluctuating demand, frequent price adjustments, and varying distributor performance often lead to inefficiencies, delayed deliveries, and misaligned targets.

According to a 2024 McKinsey study, nearly 60% of dairy manufacturers report poor visibility into distributor performance metrics, causing overproduction or missed sales opportunities.

This is where Salesforce Manufacturing Cloud delivers transformation — enabling dairy companies to bring sales, operations, and distributor networks onto one intelligent, collaborative platform.

? The Complexity of Distributor Networks in Dairy Manufacturing

The dairy ecosystem involves multiple tiers:

- Primary distributors: Handle bulk milk, butter, cheese shipments.

- Regional wholesalers: Serve specific markets with localized storage.

- Retail distributors: Supply to stores, cafés, and food service clients.

Each level introduces challenges in:

- Forecast alignment

- Pricing consistency

- Order accuracy

- Timely replenishment

Without centralized control, manufacturers often face inventory imbalances — one region overstocked, another facing shortages.

⚠️ Challenges in Managing Distributor Relationships

1️⃣ Fragmented Data Systems

Sales teams, production planners, and distributors often operate in silos, using disconnected tools.

2️⃣ Limited Forecast Transparency

Distributors lack access to real-time product availability or production updates, leading to misaligned forecasts.

3️⃣ Inefficient Rebate & Promotion Tracking

Manual claim processes create disputes and payment delays.

4️⃣ Communication Gaps

Without a centralized communication portal, updates on pricing, new SKUs, or compliance guidelines are inconsistent.

5️⃣ Lack of Real-Time KPIs

Manufacturers struggle to evaluate distributor performance across territories or brands in real time.

These challenges not only slow down operations but also weaken trust and responsiveness across the distribution chain.

? Why Collaboration Drives Profitability in Dairy Processing

Dairy products move fast — and so must the information behind them. A connected distributor network ensures that production aligns precisely with downstream demand.

Benefits of strong collaboration include:

- Fewer out-of-stock scenarios at retail points

- Reduced wastage of perishable products

- Better promotional ROI

- Stronger brand consistency across channels

- More accurate demand forecasts

A unified digital backbone ensures that manufacturers and distributors work as one team, not separate entities.

⚙️ How Salesforce Manufacturing Cloud Transforms Distributor Collaboration

1️⃣ Unified Sales Agreements & Pricing Management

Manufacturing Cloud centralizes all distributor sales agreements, including:

- Contract terms

- Volume commitments

- Rebate structures

- Region-specific pricing

Distributors and sales teams can access the same data in real time — ensuring transparency and preventing pricing discrepancies.

Example: A dairy manufacturer offering bulk cheese contracts can automatically update pricing and rebate conditions in Salesforce, instantly visible to all distributors via shared dashboards.

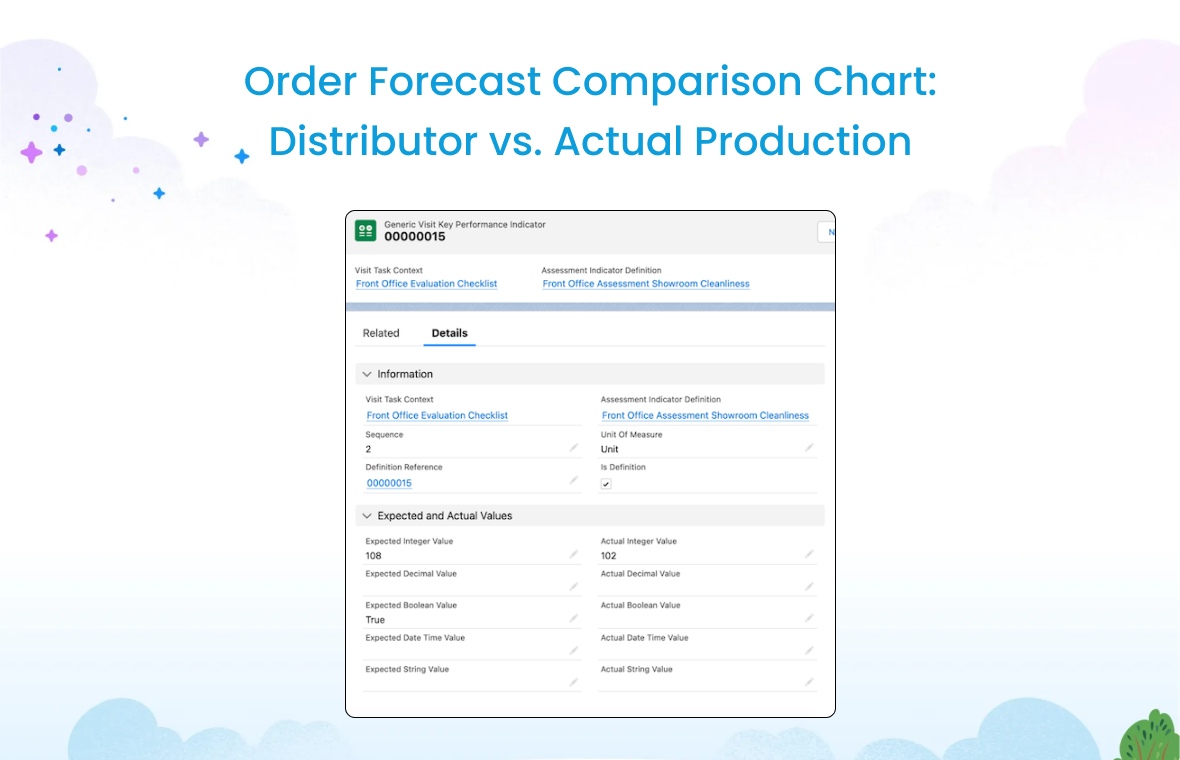

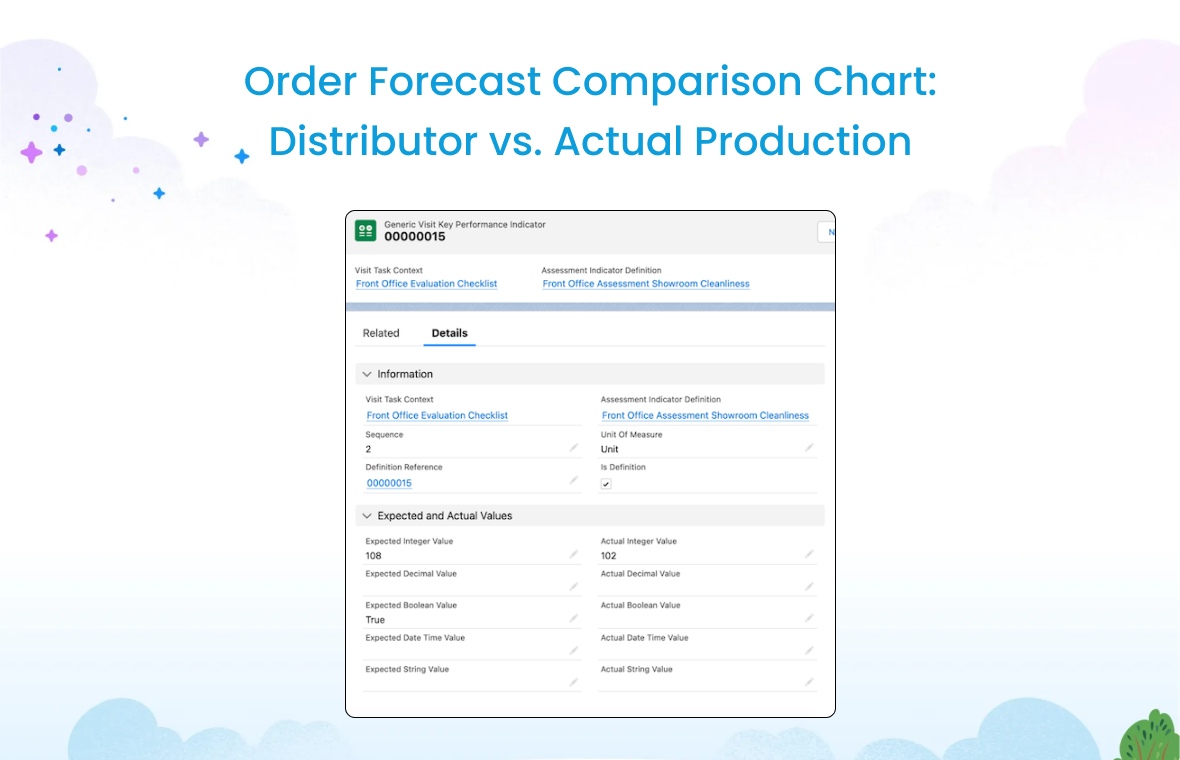

2️⃣ Real-Time Order & Forecast Visibility

Distributors gain access to live production schedules and inventory data.

This visibility helps them:

- Adjust their orders based on actual availability

- Prevent duplicate or late orders

- Synchronize marketing pushes with production capacity

Manufacturers can track distributor-level forecast accuracy and align procurement accordingly — reducing overproduction.

3️⃣ Experience Cloud Portals for Distributors

Salesforce Experience Cloud extends Manufacturing Cloud capabilities to distributors through self-service portals, where they can:

- Place and track orders

- Review current and historical sales performance

- Access promotional assets and pricing updates

- Collaborate on forecast adjustments

For dairy companies, this means streamlined communication, faster order turnaround, and improved transparency.

4️⃣ Integrated Promotions, Rebates & Claims

Managing trade promotions and rebates is often one of the biggest pain points in dairy distribution.

Salesforce automates:

- Rebate calculation based on sales volume

- Real-time validation of claim eligibility

- Approval workflows and payment tracking

This eliminates manual errors and builds trust through accurate, timely rebate settlements.

5️⃣ AI-Powered Forecasting & Performance Insights

With Einstein AI embedded in Manufacturing Cloud, manufacturers can:

- Identify distributor demand patterns

- Predict high-performing regions or SKUs

- Detect anomalies in sales performance early

AI insights enable dairy producers to proactively engage with distributors — optimizing promotional campaigns and reducing regional disparities.

? Case Study: Improving Distributor Alignment with Salesforce

Scenario (Illustrative):

A mid-sized dairy brand with 200+ distributors across three countries struggled with inconsistent sales data and misaligned forecasts.

After implementing Salesforce Manufacturing Cloud with Experience Cloud:

- Forecast accuracy improved from 70% to 91%

- Rebate settlement times reduced by 45%

- Distributor satisfaction scores increased by 30%

- Order-to-delivery cycle time shortened by 25%

Result: The company achieved tighter production alignment and 12% higher distributor-driven sales in 12 months.

? Key KPIs for Measuring Collaboration Success

- Distributor Forecast Accuracy (%)

- Rebate Claim Turnaround Time

- Order-to-Delivery Cycle (Days)

- On-Time Delivery Rate (%)

- Distributor Satisfaction Index

- Sales Growth by Territory (%)

Monitoring these metrics ensures both parties are accountable and aligned.

? The Future of Connected Dairy Ecosystems

The next evolution of dairy manufacturing will revolve around data-driven collaboration.

As Salesforce continues integrating AI, IoT, and blockchain, dairy producers can look forward to:

- Real-time cold chain validation across distributors

- AI-driven route and order optimization

- Smart contract execution for sales agreements

- Automated quality and compliance tracking

Connected ecosystems will redefine distributor relationships — making them strategic growth enablers rather than transactional channels.

? Why Partner with Perigeon Software

As a trusted Salesforce Consulting Partner, Perigeon Software helps dairy manufacturers implement, customize, and optimize Salesforce Manufacturing Cloud to:

- Digitize distributor engagement using Experience Cloud

- Automate rebate, claim, and pricing processes

- Create intelligent dashboards for forecast and sales tracking

- Integrate ERP and logistics systems for unified visibility

Our industry-specific expertise ensures your Salesforce investment directly translates to efficiency, transparency, and growth.

Conclusion

Distributor collaboration is the foundation of success in the dairy industry. By leveraging Salesforce Manufacturing Cloud, dairy producers can achieve real-time visibility, transparent pricing, faster communication, and data-driven decision-making.

With a unified collaboration model powered by Salesforce — and implemented by Perigeon Software — dairy manufacturers can ensure every distributor becomes a strategic partner in delivering freshness, efficiency, and profitability.