Table of content

Introduction

The Complexities of Apparel Order Management

Key Challenges in Apparel Manufacturing

Why Visibility and Agility Are Business-Critical

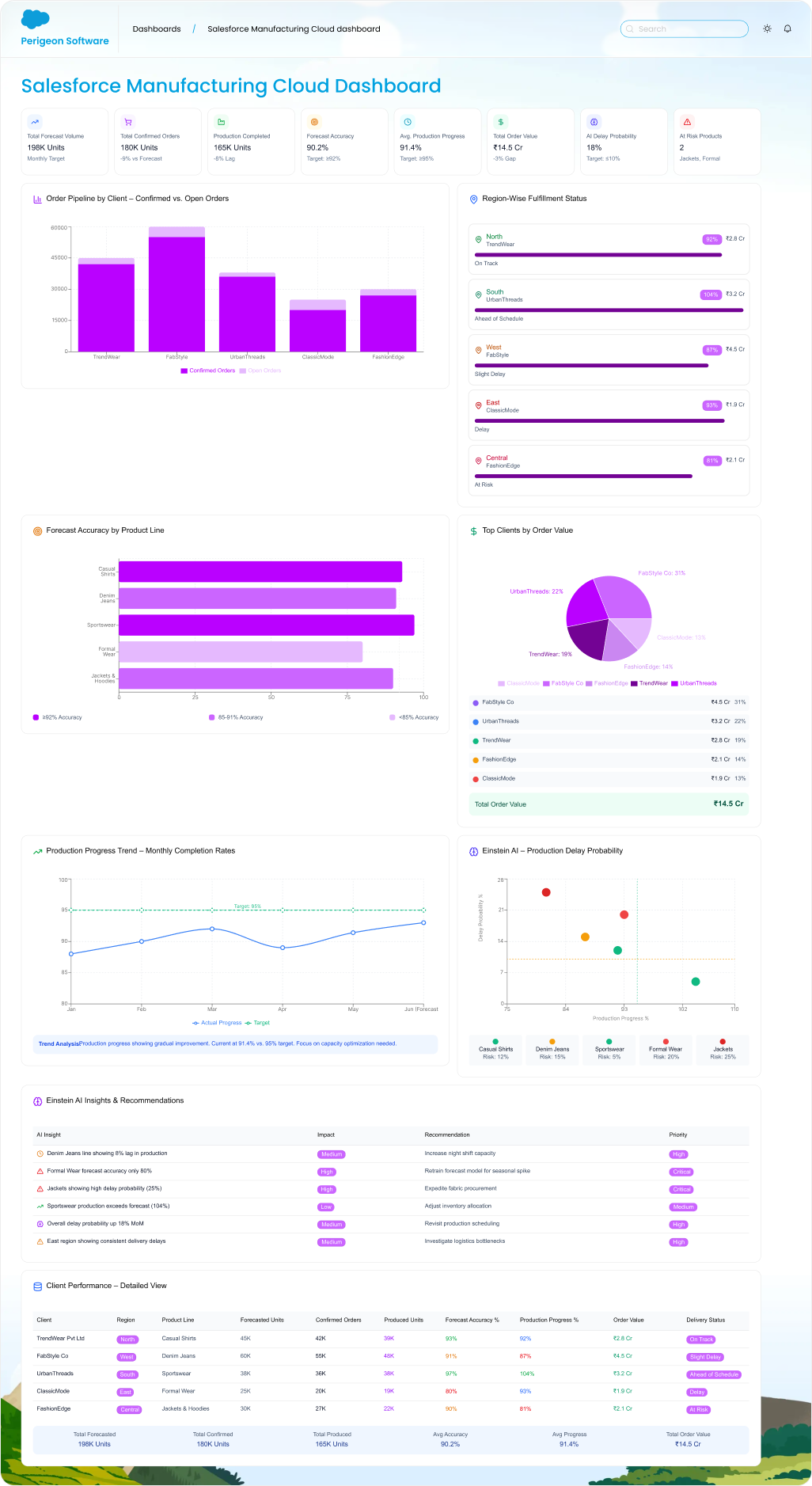

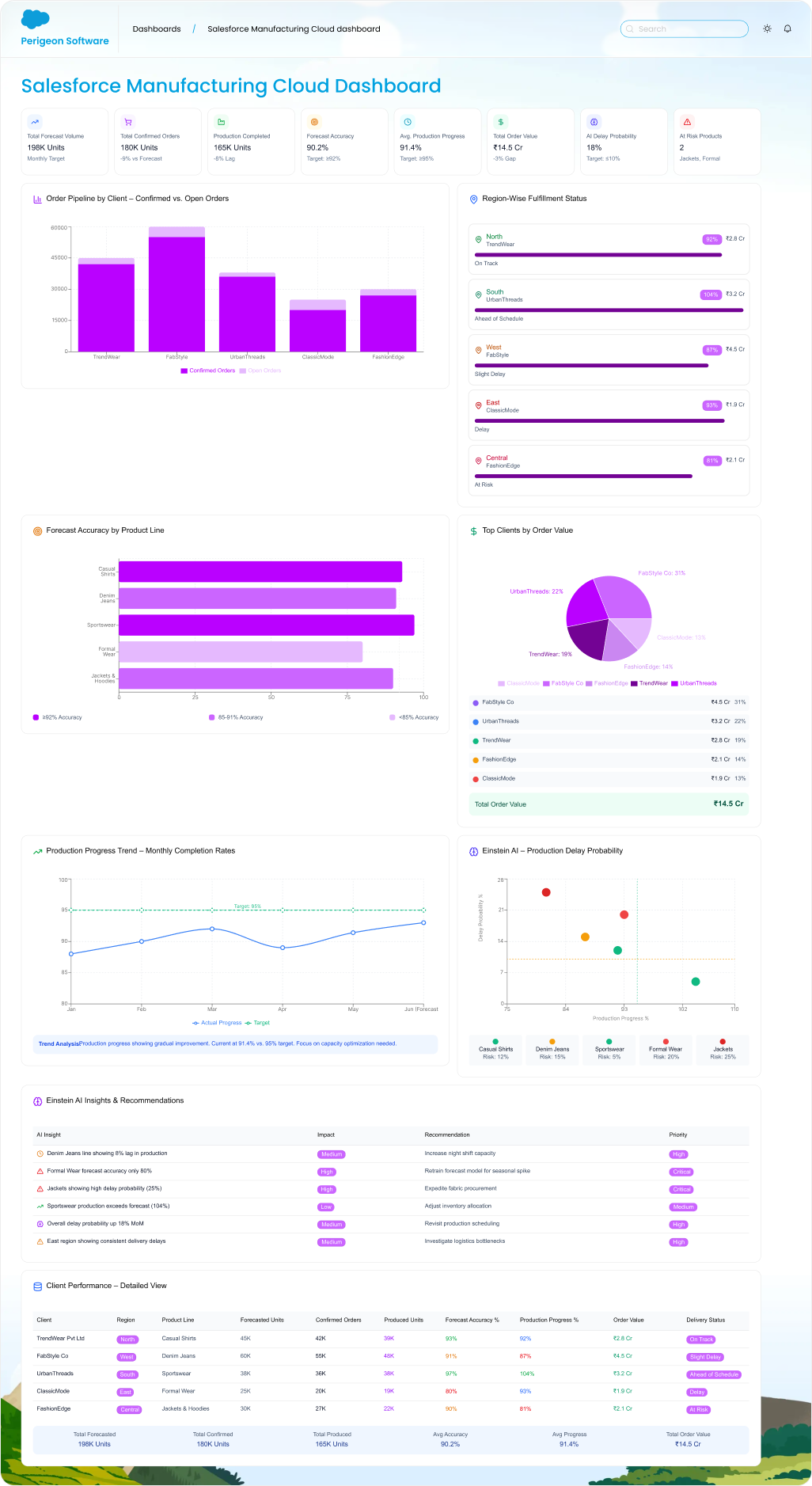

How Salesforce Manufacturing Cloud Simplifies Complex Apparel Orders

Case Study: A Global Apparel Brand’s Salesforce Transformation

Key KPIs to Measure Apparel Order Management Efficiency

The Future of Digital Manufacturing in Apparel

Why Partner with Perigeon Software

Conclusion

👕 Introduction

In today’s fashion and apparel industry, complex order management has become the norm rather than the exception.

From seasonal collections and custom designs to multi-channel fulfillment, manufacturers juggle thousands of SKUs, fabrics, and regional variations every quarter.

According to Statista, the global apparel market exceeded $1.7 trillion in 2024, and by 2028, digital order management will account for more than 60% of apparel production planning.

The industry is moving fast — but manual systems can’t keep up. That’s where Salesforce Manufacturing Cloud helps apparel manufacturers gain real-time visibility, unify sales and production teams, and streamline the entire order lifecycle — from contract to delivery.

🧵 The Complexities of Apparel Order Management

Unlike standard manufacturing, apparel production involves:

- Seasonal demand spikes

- Color, size, and style variations per product

- Dynamic pricing and rebate programs

- Multiple suppliers and fabric sourcing timelines

- Stringent delivery windows for retailers

This multi-layered environment requires precise planning and collaboration across sales, production, and logistics teams — something that traditional ERP systems alone struggle to deliver.

⚠️ Key Challenges in Apparel Manufacturing

1.SKU Explosion: A single garment can have dozens of SKUs due to size, color, and fit variations.

2.Fragmented Systems: Design, procurement, and sales teams often operate in silos, leading to communication breakdowns.

3.Forecast Inaccuracy: Demand for styles can shift rapidly due to fashion trends, leading to excess inventory or missed sales.

4.Complex Customer Agreements: Retailers often negotiate unique contracts with dynamic pricing, rebates, and order volumes.

5.Slow Order Tracking: Legacy systems can’t provide real-time updates across production and logistics, delaying shipments.

💡 Why Visibility and Agility Are Business-Critical

The apparel industry’s success depends on speed, precision, and adaptability.

Brands must respond instantly to new trends, seasonal shifts, and consumer preferences.

By consolidating order data and forecasting insights, Salesforce Manufacturing Cloud helps apparel manufacturers:

- Cut response times to retail partners by up to 40%

- Improve forecast accuracy by 25–30%

- Reduce production bottlenecks through real-time visibility

“Salesforce gives apparel companies the agility to react to global market changes — while ensuring brand consistency and profitability.” — Perigeon Software Industry Insights

⚙️ How Salesforce Manufacturing Cloud Simplifies Complex Apparel Orders

1️⃣ Centralized Sales Agreements and Order Management

Manufacturing Cloud unifies all retailer and distributor agreements in one place.

This means:

- No more manual contract updates

- Consistent pricing and volume commitments across regions

- Automated renewals and rebate management

Apparel manufacturers can view the full lifecycle of every contract and order — from initial quote to fulfillment — ensuring nothing slips through the cracks.

Example: A dairy manufacturer offering bulk cheese contracts can automatically update pricing and rebate conditions in Salesforce, instantly visible to all distributors via shared dashboards.

2️⃣ Real-Time Production Planning & Forecast Accuracy

By connecting sales and operations data, Salesforce enables planners to adjust production dynamically based on real demand.

Example:

If a new style’s demand exceeds forecasts in North America, production teams can shift capacity from underperforming SKUs — all visible in real-time dashboards.

Benefits include:

- Reduction in excess inventory

- Faster production cycles

- More responsive supply chains

3️⃣ Omnichannel Collaboration with Distributors and Retailers

Through Salesforce Experience Cloud, apparel manufacturers can provide retail partners with self-service portals where they can:

- Track order status

- View available stock and upcoming production batches

- Request changes or reorder high-selling items

- Collaborate on new product launches

This level of transparency strengthens long-term relationships and ensures alignment between production schedules and retailer needs.

4️⃣ Integration with ERP and PLM Systems

Apparel production requires seamless coordination between design (PLM), procurement, and finance (ERP).

Salesforce Manufacturing Cloud integrates easily with leading ERP and PLM solutions — enabling unified data flow for:

- Fabric and raw material tracking

- Production cost monitoring

- Automated work order creation

- Quality control updates

The result is a single source of truth that connects the creative process to operational execution.

5️⃣ AI-Driven Insights for Smarter Decision-Making

With Einstein AI, manufacturers can identify emerging order trends, predict bottlenecks, and optimize resource allocation.

AI-driven forecasting also helps determine which apparel lines are most profitable — allowing teams to prioritize high-margin products.

“Apparel manufacturers leveraging AI insights see up to 18% faster order-to-cash cycles and 20% reduction in unplanned inventory.” — Forrester, 2024 Manufacturing AI Report

🧮 Case Study: A Global Apparel Brand’s Salesforce Transformation

A Europe-based fashion brand managing over 15,000 active SKUs faced major challenges in order visibility and forecast accuracy.

After implementing Salesforce Manufacturing Cloud, the company achieved:

- 35% improvement in forecast accuracy

- 40% faster quote-to-order process

- 25% reduction in late shipments

- Unified view of all distributor and retailer agreements

Now, their production, finance, and sales teams work off the same dashboards, enabling agile decision-making and better profitability.

📊 Key KPIs to Measure Apparel Order Management Efficiency

- Forecast Accuracy (%)

- Order-to-Production Cycle Time

- On-Time Delivery Rate (%)

- Rebate Settlement Time

- SKU-Level Profitability

- Distributor Satisfaction Index

These KPIs help manufacturers continuously refine their operations for higher output and lower waste.

🔮 The Future of Digital Manufacturing in Apparel

By 2030, apparel supply chains will be digitally autonomous, leveraging AI, IoT, and cloud-based collaboration.

Future Salesforce integrations will enable:

- Real-time sustainability tracking (carbon footprint per garment)

- IoT sensors in production lines for predictive maintenance

- Automated order adjustment based on consumer sentiment data

- Blockchain-backed order transparency

The convergence of data, design, and digital collaboration will redefine apparel manufacturing for the next decade.

🤝 Why Partner with Perigeon Software

As a Salesforce Consulting Partner, Perigeon Software helps apparel and textile manufacturers transform complex order management using Salesforce Manufacturing Cloud.

Our services include:

- End-to-end Manufacturing Cloud implementation

- Integration with ERP, PLM, and inventory systems

- Automation of sales agreements, rebates, and forecasting

- AI-powered dashboards for real-time visibility

With deep manufacturing expertise, we enable apparel brands to move from reactive order processing to proactive supply orchestration.

Conclusion

Apparel manufacturers operate in one of the most dynamic, fast-paced industries in the world. Managing complex orders requires a unified, intelligent platform that connects every stakeholder — from design to delivery.

Salesforce Manufacturing Cloud, implemented by Perigeon Software, empowers manufacturers to streamline operations, gain real-time visibility, and deliver excellence across every order, region, and customer.

In a market driven by agility, visibility, and speed, Salesforce is not just a platform — it’s your competitive edge.