Table of content

Introduction

The Challenge of Forecasting in Fashion Manufacturing

Impact of Poor Forecast Accuracy on the Fashion Industry

Why Traditional Forecasting Models Fall Short

How Salesforce Manufacturing Cloud Enhances Forecast Accuracy

Case Study: Improving Fashion Forecast Accuracy with Salesforce

Key Forecasting Metrics for Fashion Manufacturers

The Role of AI & Analytics in Future-Ready Fashion

Why Partner with Perigeon Software

Conclusion

? Introduction

Forecasting in the fashion industry has always been more art than science — but the stakes have never been higher.

With changing consumer preferences, global supply chain disruptions, and shorter trend cycles, fashion manufacturers must evolve from reactive planning to proactive forecasting.

According to McKinsey’s State of Fashion 2024 Report, more than 45% of fashion companies cite demand unpredictability as their top profitability challenge, while brands using AI-driven forecasting report up to 30% lower inventory waste.

This is exactly where Salesforce Manufacturing Cloud transforms the game — unifying production, sales, and retail data to help manufacturers accurately predict demand and plan capacity with precision.

? The Challenge of Forecasting in Fashion Manufacturing

Unlike other industries, fashion is inherently volatile.

Forecasting becomes complex due to factors like:

- Rapid trend changes: Influencer culture and social media accelerate demand shifts.

- Short product life cycles: Styles change every season — sometimes every month.

- Regional variation: Demand differs widely across countries and climates.

- Promotional impacts: Flash sales or influencer drops can skew forecasts dramatically.

- Supplier constraints: Raw material lead times limit flexibility.

This means traditional spreadsheet-based forecasting can’t handle the pace or complexity of modern apparel production.

⚠️ Impact of Poor Forecast Accuracy on the Fashion Industry

Poor forecasting affects every layer of the business:

- ❌ Overproduction: Leads to unsold inventory and markdown losses.

- ❌ Underproduction: Causes stockouts, lost sales, and reduced customer loyalty.

- ❌ Inefficient capacity planning: Factories and suppliers struggle to adapt to fluctuating schedules.

- ❌ Financial strain: Misalignment between production and demand hurts margins.

A Deloitte study found that fashion manufacturers lose 10–15% of potential revenue annually due to inaccurate forecasts.

The need for a smarter, data-connected system is undeniable — and Salesforce provides the platform to achieve that.

? Why Traditional Forecasting Models Fall Short

Many apparel companies still rely on:

- Spreadsheets updated manually by regional sales teams

- Historical sales data without real-time inputs

- Disconnected ERP and CRM systems

- Limited visibility into distributor or retail sell-through data

These limitations create blind spots that make it impossible to adapt to fast-changing demand.

The solution lies in connected forecasting, powered by Salesforce Manufacturing Cloud.

⚙️ How Salesforce Manufacturing Cloud Enhances Forecast Accuracy

1️⃣ Unified Data from Sales, Operations & Retail

Manufacturing Cloud brings all relevant business data into a single platform — from wholesale orders to retail sell-through metrics.

Fashion manufacturers gain a 360° view of demand, allowing them to forecast not just based on past trends, but on real-time customer behavior.

Example: A denim manufacturer can see how sales are performing at retail stores, factor in online orders, and update production forecasts instantly.

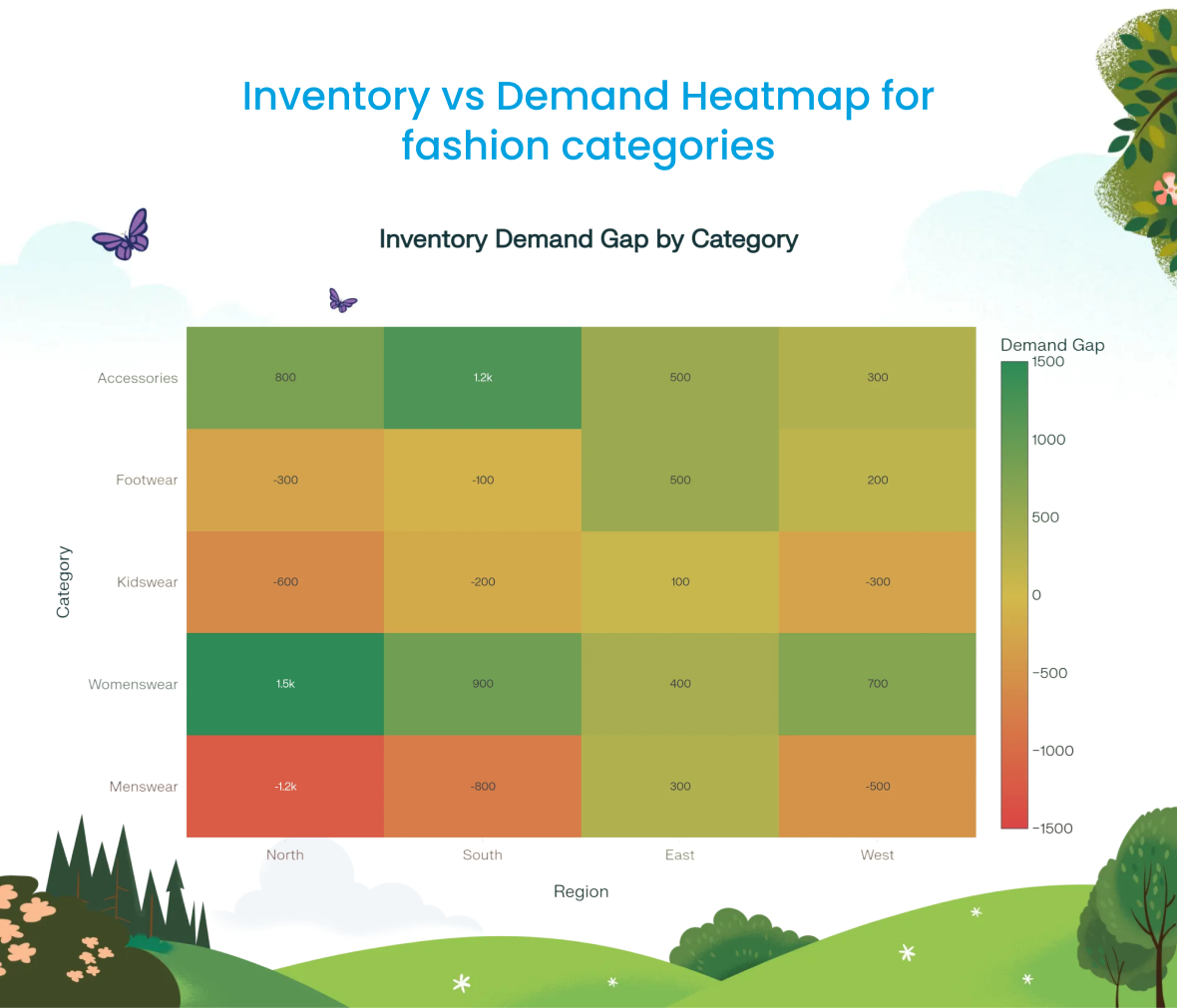

2️⃣ Real-Time Demand & Inventory Visibility

Salesforce connects sales, operations, and inventory data in real time, allowing teams to:

- Track order fulfillment and production progress

- Identify gaps between forecasted and actual demand

- Reallocate production resources dynamically

This ensures inventory levels align perfectly with demand fluctuations, reducing overstock and shortages.

3️⃣ AI-Driven Predictive Forecasting

The integration of Einstein AI in Manufacturing Cloud introduces predictive analytics that helps fashion companies:

- Anticipate demand by region, style, or SKU

- Identify seasonal trends before they peak

- Detect anomalies in sales performance

- Generate rolling forecasts updated automatically

For example, Einstein can predict that pastel-colored clothing will see a 15% increase in demand next quarter in Southern markets based on weather and search trends.

“Brands using AI-driven forecasts see up to 40% faster inventory turns and 25% higher sell-through rates.” — Salesforce Industry Research 2024

4️⃣ Collaboration Across Suppliers & Distributors

Manufacturing Cloud, combined with Experience Cloud, enables collaborative forecasting.

Suppliers, retailers, and distributors can share updates on material lead times, retail sales, and expected returns — allowing synchronized demand planning.

This eliminates bottlenecks caused by siloed communication and ensures everyone in the value chain works from a single source of truth.

5️⃣ Scenario Planning & Seasonal Adjustments

Fashion thrives on seasonality — and so must its forecasts.

Manufacturing Cloud allows planners to run “what-if” scenarios based on changing variables such as:

- Market promotions

- New collection launches

- Raw material delays

- Regional buying patterns

Planners can simulate the impact on production, cost, and delivery timelines — helping decision-makers choose the most profitable strategy.

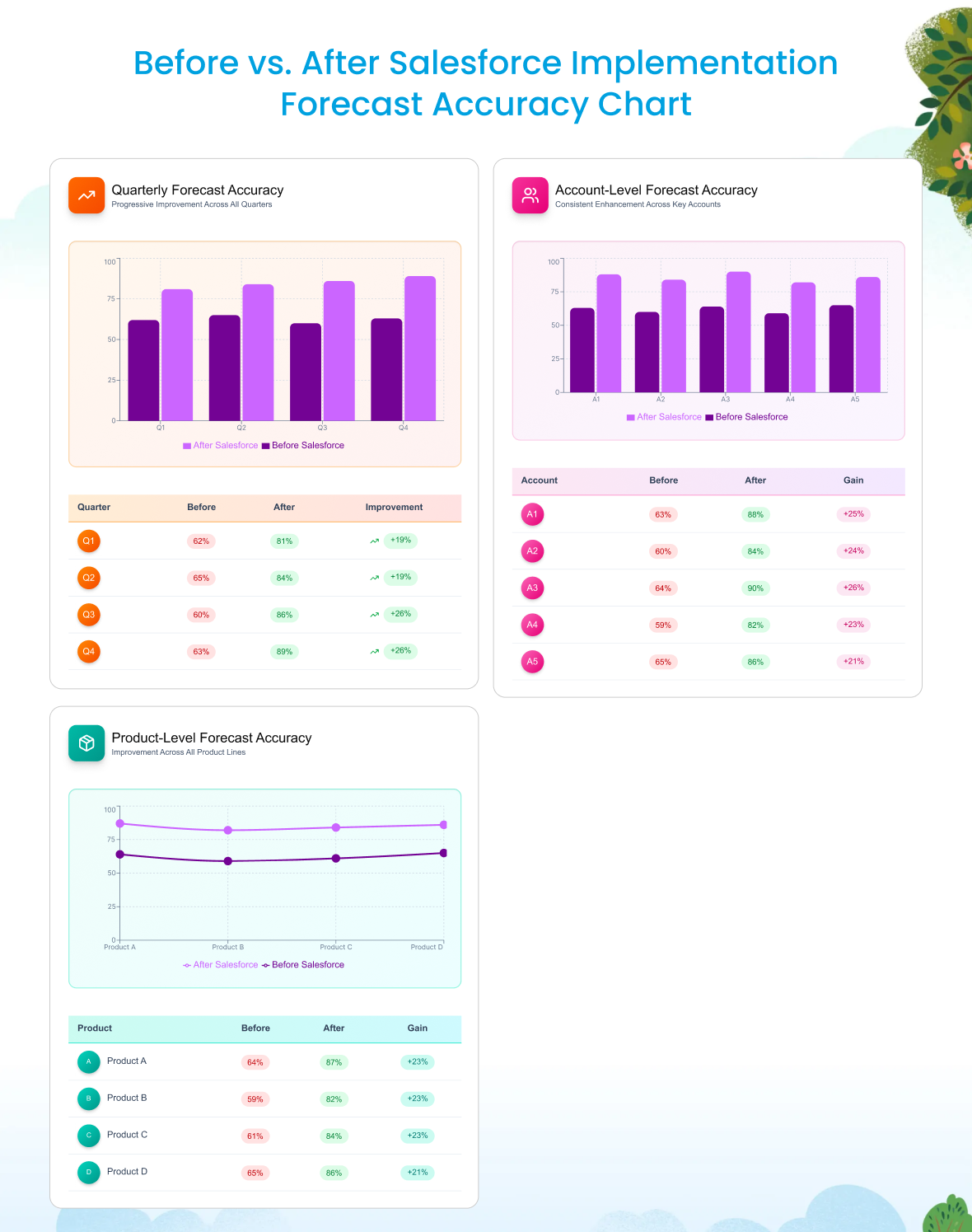

? Case Study: Improving Forecast Accuracy in Fashion with Salesforce

Scenario:

A global sportswear brand with 30+ product categories struggled with forecasting accuracy across regions.

Challenges:

- Disconnected sales & production systems

- Seasonal surpluses and shortages

- Limited visibility into retailer demand

Solution:

After implementing Salesforce Manufacturing Cloud:

- Forecast accuracy improved from 68% to 92%

- Order cycle time reduced by 35%

- Overproduction cut by 28%

- Gross margin improved by 8% year-over-year

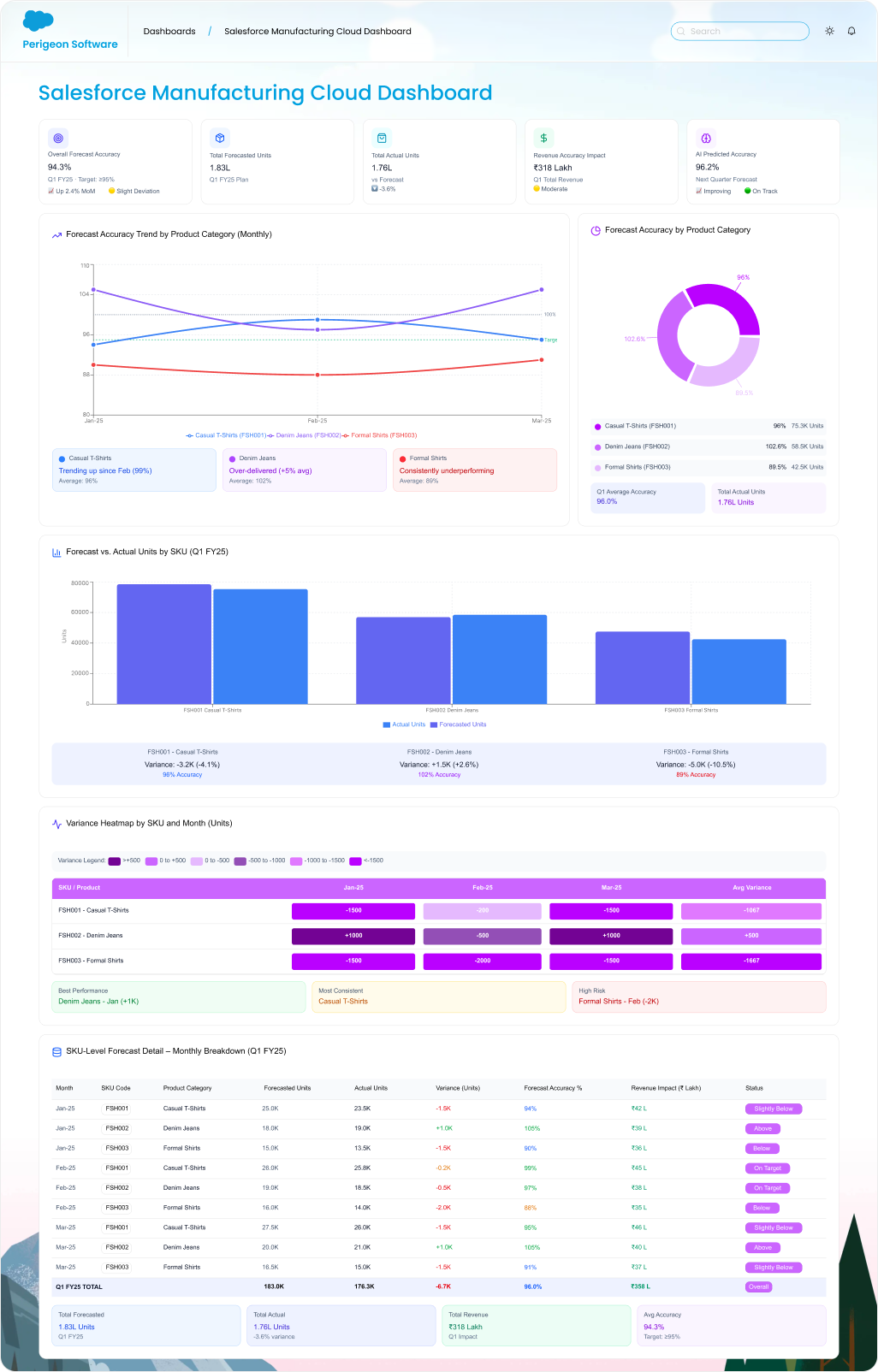

? Key Forecasting Metrics for Fashion Manufacturers

Fashion manufacturers can monitor success through the following KPIs:

- Forecast Accuracy (%)

- Inventory Turnover Ratio

- Demand Variance by SKU

- On-Time Order Fulfillment (%)

- Sell-Through Rate (%)

- Markdown Ratio

With Salesforce dashboards, these KPIs update in real time — giving leadership visibility across brands, seasons, and geographies.

? The Role of AI & Analytics in Future-Ready Fashion

The future of fashion manufacturing will be driven by data, automation, and predictive intelligence.

Upcoming Salesforce advancements are set to include:

- Deeper AI models for trend prediction based on social and search data

- IoT-based demand sensing from in-store and eCommerce channels

- Blockchain-enabled supply transparency for ethical sourcing

- Sustainability forecasting, tracking carbon impact per product line

With these innovations, manufacturers will shift from “forecasting demand” to orchestrating supply and demand in real time.

? Why Partner with Perigeon Software

Perigeon Software helps fashion manufacturers unlock the full potential of Salesforce Manufacturing Cloud through:

- Industry-specific implementation strategies

- Forecasting automation & analytics dashboards

- ERP and retail system integration

- AI-powered reporting tailored for fashion cycles

- Real-time collaboration portals for distributors and suppliers

As a Salesforce Consulting Partner, Perigeon brings domain expertise, technical excellence, and proven results — enabling manufacturers to transform volatility into predictability.

? Conclusion

In the fast-changing world of fashion, forecast accuracy is the new currency of success.

With Salesforce Manufacturing Cloud, manufacturers gain real-time visibility, predictive intelligence, and agile decision-making across global operations.

Partnering with Perigeon Software ensures that every forecast becomes actionable — turning data into demand, and demand into profit.