Table of content

Introduction

The Complexity of Footwear Production Planning

Key Challenges in Footwear Manufacturing Operations

Why Salesforce Manufacturing Cloud Is a Game-Changer

How Manufacturing Cloud Optimizes Footwear Production Planning

Case Study: A Global Footwear Brand Improves Planning Efficiency

Tangible Business Outcomes

The Future of Smart Production Planning in Footwear

Why Partner with Perigeon Software

Conclusion

? Introduction

The global footwear industry moves fast — driven by seasonal trends, evolving consumer preferences, and complex production processes.From sneakers to formal wear, every footwear manufacturer faces the same challenge: producing the right styles, in the right quantities, at the right time.

But with fragmented sales data, disconnected planning tools, and unpredictable demand cycles, many manufacturers end up overproducing or missing market opportunities altogether.

Salesforce Manufacturing Cloud empowers footwear brands to take control of production planning — aligning demand, inventory, and capacity in real time.

It replaces reactive decision-making with predictive intelligence, helping manufacturers optimize output, reduce waste, and accelerate time to market.

“In footwear manufacturing, planning isn’t just about production — it’s about precision, timing, and insight.”

? The Complexity of Footwear Production Planning

Footwear production is inherently complex due to:

- A wide range of sizes, styles, and materials

- Multiple product lines across regions and seasons

- Collaboration with suppliers, designers, and retailers

- Variable production times for different footwear categories

For manufacturers, planning requires accurate data from multiple departments — sales, inventory, logistics, and supply chain.

Without integration, these silos cause delays and inefficiencies.

⚙️ Key Challenges in Footwear Manufacturing Operations

1.Unreliable Demand Forecasts — Seasonal demand and retail fluctuations lead to inaccurate production schedules.

2.Disconnected Systems — ERP, CRM, and inventory systems often fail to share data in real time.

3.Material Shortages or Overstocking — Poor supplier visibility leads to raw material delays or excess storage.

4.Manual Planning Processes — Spreadsheets and legacy tools limit scalability and speed.

5.Limited Production Agility — Manufacturers can’t easily adjust when market conditions shift.

The result? Higher operational costs, missed delivery targets, and strained supplier relationships.

? Why Salesforce Manufacturing Cloud Is a Game-Changer

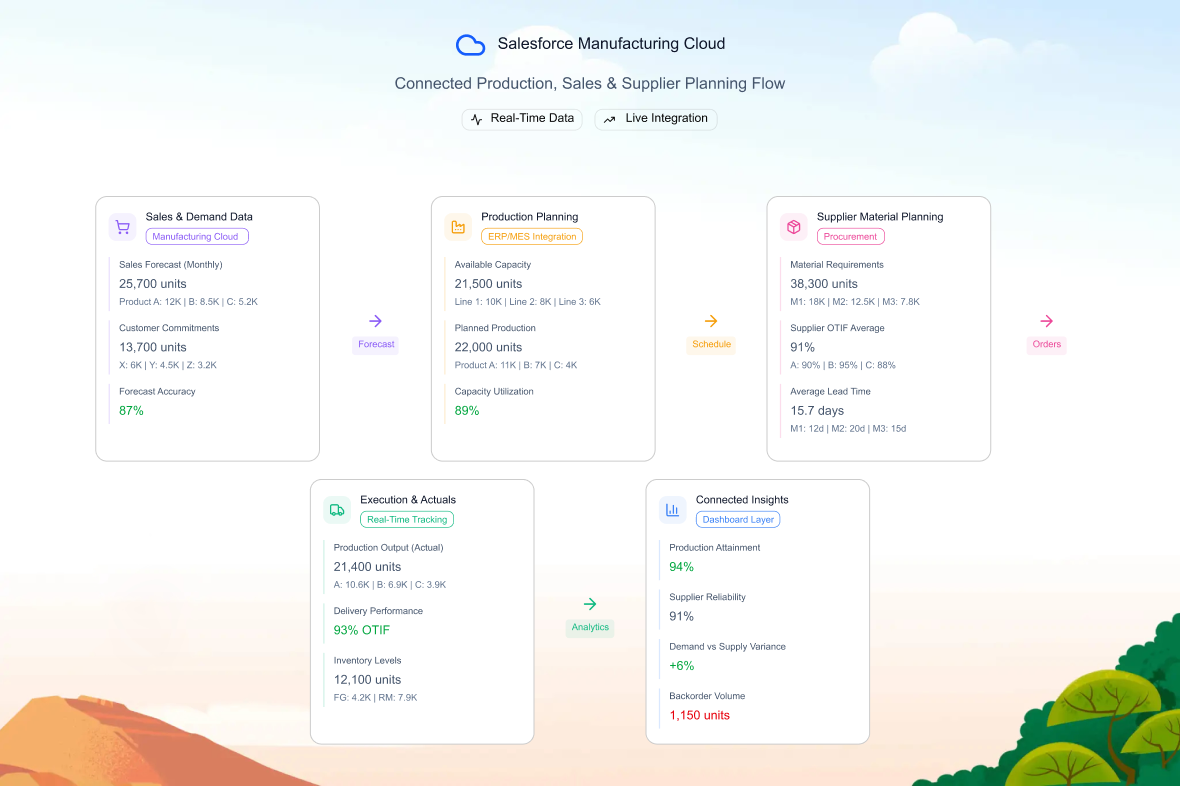

Salesforce Manufacturing Cloud centralizes sales, operations, and supply chain planning in one intelligent platform.

It connects:

- Sales agreements with real-time demand data

- Production capacity with supplier readiness

- Forecast accuracy with AI-driven insights

This unified visibility allows footwear manufacturers to plan proactively, not reactively — optimizing production cycles and aligning resources to demand.

? How Manufacturing Cloud Optimizes Footwear Production Planning

1️⃣ Unified Demand & Sales Data

Manufacturing Cloud consolidates sales agreements, orders, and retail forecasts into a single source of truth.

Footwear manufacturers can:

- Track confirmed orders vs. projected demand

- Align production with channel-specific forecasts

- View sales trends by SKU, region, or season

By linking sales and operations, planners can ensure that every production batch aligns with real-world demand, minimizing surplus or shortages.

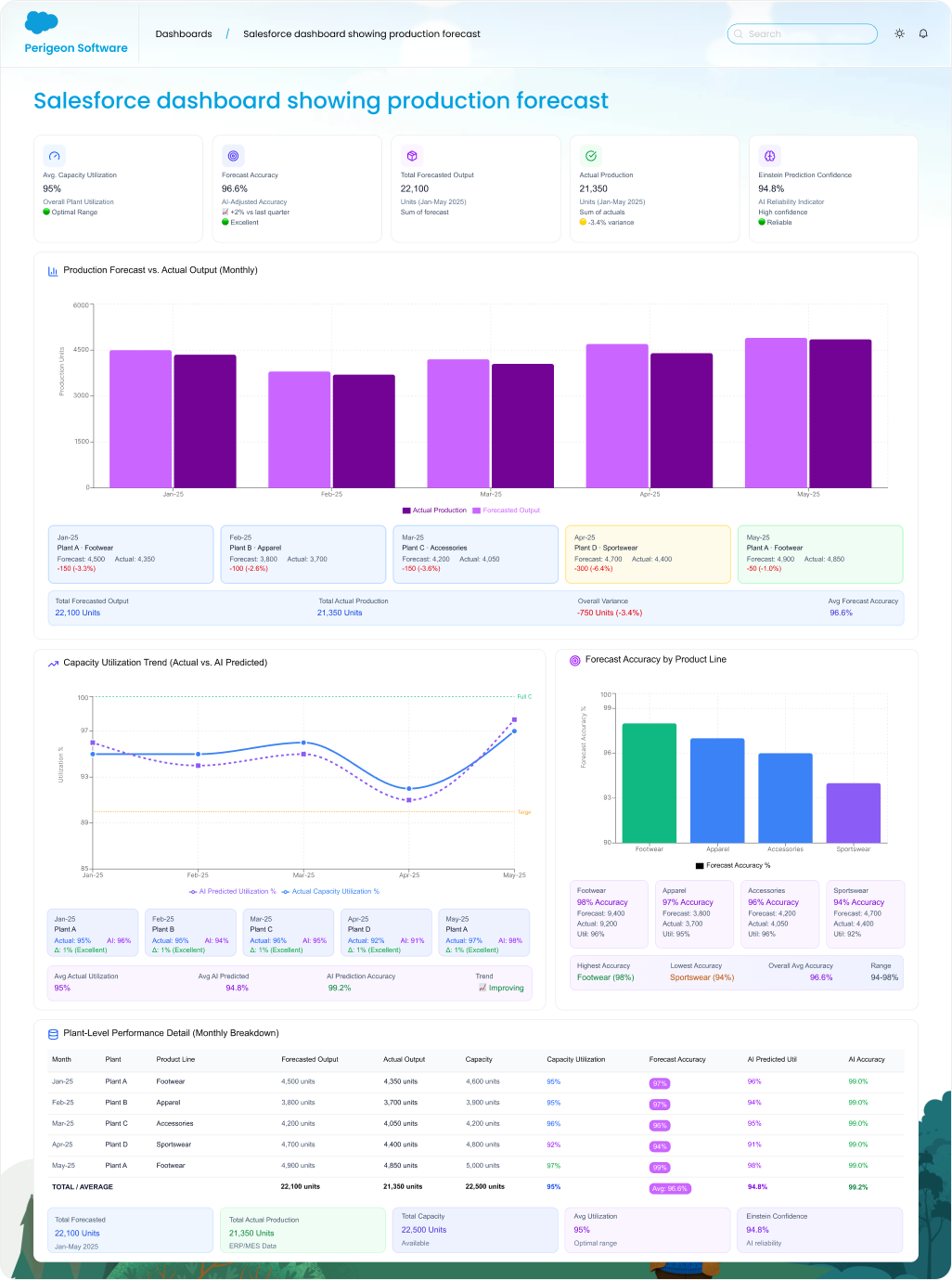

2️⃣ Intelligent Forecasting & Capacity Planning

Using Salesforce Einstein Analytics, Manufacturing Cloud employs machine learning to anticipate demand trends.

It helps production managers:

- Predict material and labor requirements

- Balance factory workloads and shifts

- Identify capacity gaps before they disrupt schedules

For example, Einstein might identify that a specific sneaker line is trending 20% higher than projected — triggering an automatic capacity adjustment.

3️⃣ Streamlined Supplier & Material Coordination

Footwear production relies on a vast network of suppliers — from leather and rubber to packaging and dyes.

Manufacturing Cloud integrates supplier data via Experience Cloud portals, providing:

- Visibility into raw material availability

- Real-time updates on shipment timelines

- Alerts for delays or substitutions

This ensures material readiness aligns with production schedules, preventing costly idle time or production halts.

4️⃣ Real-Time Production Visibility

With Salesforce, operations teams can monitor every stage of production — from design approval to final assembly.

Manufacturers gain:

- Live dashboards on work orders and job status

- Automated alerts for bottlenecks or quality issues

- Performance metrics by factory or production line

This real-time oversight empowers leaders to make data-driven adjustments instantly, maintaining consistent quality and delivery timelines.

5️⃣ Agile Response to Market & Design Changes

In fashion and footwear, agility is everything.

With Manufacturing Cloud, planners can run “what-if” simulations for new product lines or design updates.

For instance:

- If a retailer increases demand for a trending design, production capacity can be recalibrated in hours.

- If a new material becomes unavailable, Salesforce automatically updates dependent schedules and supplier orders.

This adaptability helps manufacturers remain competitive — even in rapidly changing retail environments.

? Case Study: A Global Footwear Brand Improves Planning Efficiency

Scenario:

A leading athletic footwear manufacturer producing over 10 million pairs annually struggled with delayed production schedules and unpredictable supplier lead times.

Challenges:

- Disconnected systems between sales and production

- Inaccurate forecasts due to limited data visibility

- Production overruns and missed retail deadlines

Solution Implemented by Perigeon Software:

- Salesforce Manufacturing Cloud integrated with ERP & supplier portals

- AI-driven forecasting via Einstein Analytics

- Real-time production dashboards for global visibility

Results:

- Forecast accuracy improved by 35%

- Production cycle times reduced by 25%

- Material wastage dropped by 18%

- On-time delivery rate increased to 97%

? Tangible Business Outcomes

Footwear manufacturers using Salesforce Manufacturing Cloud typically achieve:

- 25–30% improvement in production planning accuracy

- 20% reduction in operational costs

- 15–20% faster time-to-market for new styles

- 30% better supplier coordination and transparency

By connecting every stakeholder — from sales to production — Salesforce enables true end-to-end operational excellence.

? The Future of Smart Production Planning in Footwear

The next era of footwear production will be defined by data-driven automation, AI-powered scheduling, and predictive manufacturing.

Future Salesforce capabilities will include:

- IoT-integrated machinery monitoring for proactive maintenance

- Sustainability dashboards tracking material utilization and waste

- Blockchain traceability for ethical sourcing

- AI-augmented production planning that auto-adjusts schedules in real time

This convergence of AI, analytics, and automation will allow manufacturers to move from forecasting to foresight — achieving precision planning at scale.

? Why Partner with Perigeon Software

Perigeon Software is a trusted Salesforce Consulting Partner specializing in transforming footwear and apparel manufacturing operations.

We help manufacturers:

- Implement Salesforce Manufacturing Cloud with custom workflows

- Design forecasting dashboards & analytics tailored to product complexity

- Integrate ERP, PLM, and inventory systems seamlessly

- Enable supplier and retail collaboration through Experience Cloud

- Drive continuous optimization through post-deployment analytics

With deep industry expertise and Salesforce specialization, Perigeon Software empowers footwear brands to achieve smarter, faster, and more sustainable production planning.

? Conclusion

In footwear manufacturing, every minute and material counts. Salesforce Manufacturing Cloud provides the intelligence, visibility, and agility manufacturers need to turn planning into a competitive advantage.

By connecting data, people, and processes, it ensures production always aligns with demand — minimizing waste and maximizing profitability.

With Perigeon Software as your Salesforce partner, you can step confidently into the future of intelligent manufacturing — where precision meets performance.