Table of content

Introduction

The Importance of Distributor Collaboration in Shoe Manufacturing

Current Challenges in Managing Distributor Relationships

Why Salesforce Manufacturing Cloud Is the Ideal Solution

How Manufacturing Cloud Strengthens Distributor Collaboration

Case Example: A Global Shoe Manufacturer Streamlines Distributor Coordination

Measurable Business Impact

The Future of Distributor Collaboration in the Footwear Industry

Why Partner with Perigeon Software

Conclusion

👟 Introduction

Shoe manufacturing isn’t just about crafting great footwear — it’s about ensuring the right pairs reach the right markets at the right time.

For manufacturers, distributor collaboration is critical to success.

However, in an industry with global retail networks and seasonal demand fluctuations, maintaining real-time alignment with distributors is often challenging. Miscommunication or delayed updates can lead to overstocking, shortages, and missed opportunities.

Salesforce Manufacturing Cloud transforms this ecosystem by connecting manufacturers and distributors on one intelligent platform — enabling real-time collaboration, accurate forecasting, and data-driven decision-making.

“When manufacturers and distributors work in sync, every step — from factory to foot — becomes more efficient.”

🔗 The Importance of Distributor Collaboration in Shoe Manufacturing

Distributors are the bridge between manufacturers and the retail marketplace.

For footwear brands, these partnerships determine how efficiently products are launched, promoted, and sold across regions.

Strong collaboration ensures:

- Faster market entry for new shoe lines

- Balanced inventory across geographies

- Fewer logistical disruptions

- Improved sell-through rates

In a market driven by fast-changing trends, agility and communication define profitability.

⚠️ Current Challenges in Managing Distributor Relationships

Many footwear manufacturers face recurring issues when managing distributor networks:

- 1. Data Silos: Sales data sits in emails, spreadsheets, or legacy systems with no single source of truth.

- 2. Limited Visibility: Manufacturers lack real-time insight into distributor stock or order status.

- 3. Forecast Inaccuracy: Without synchronized data, demand forecasts are often reactive and error-prone.

- 4. Inefficient Order Communication: Manual order tracking leads to misalignment between production and delivery.

- 5. Complex Rebate Structures: Managing incentives and volume-based rebates manually results in errors and delays.

The outcome? Lost sales, inventory bottlenecks, and strained relationships with distributors.

💡 Why Salesforce Manufacturing Cloud Is the Ideal Solution

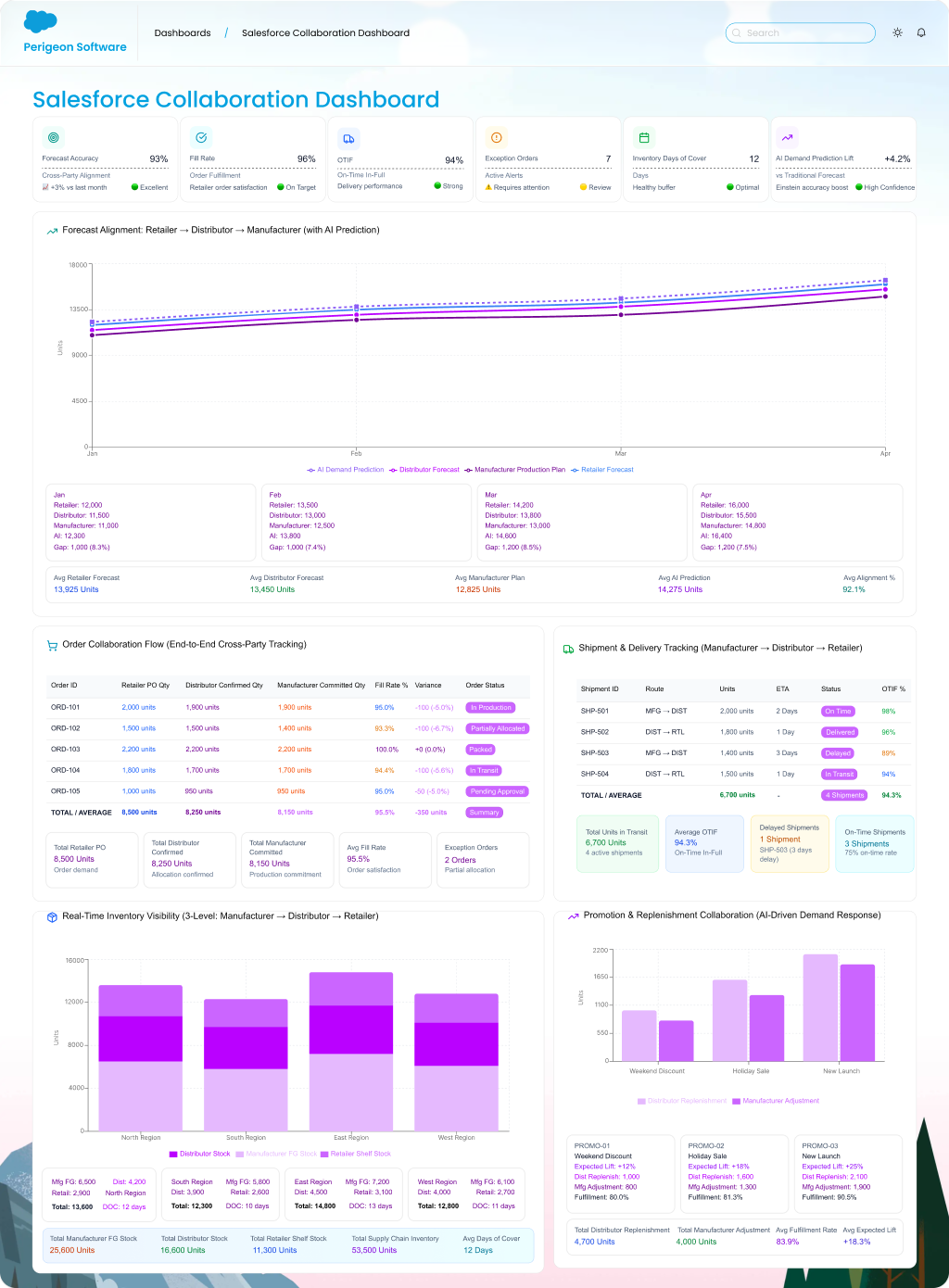

Salesforce Manufacturing Cloud provides a unified digital framework for end-to-end distributor collaboration.

It consolidates sales, operations, and partner engagement data into one ecosystem, ensuring every stakeholder has the same, real-time view.

Manufacturers can:

- Track distributor performance and order trends

- Manage sales agreements transparently

- Forecast demand with precision

- Enable proactive communication and faster decision-making

It shifts distributor relationships from transactional to strategic — driving shared growth and mutual profitability.

⚙️ How Manufacturing Cloud Strengthens Distributor Collaboration

1️⃣ Unified View of Sales Agreements

All distributor contracts, terms, and volume commitments are stored and managed in Salesforce Manufacturing Cloud.

Manufacturers can:

- Track performance against agreed targets

- Monitor order status vs. commitments

- Automate renewals and pricing adjustments

This transparency ensures alignment between planning, production, and distribution goals.

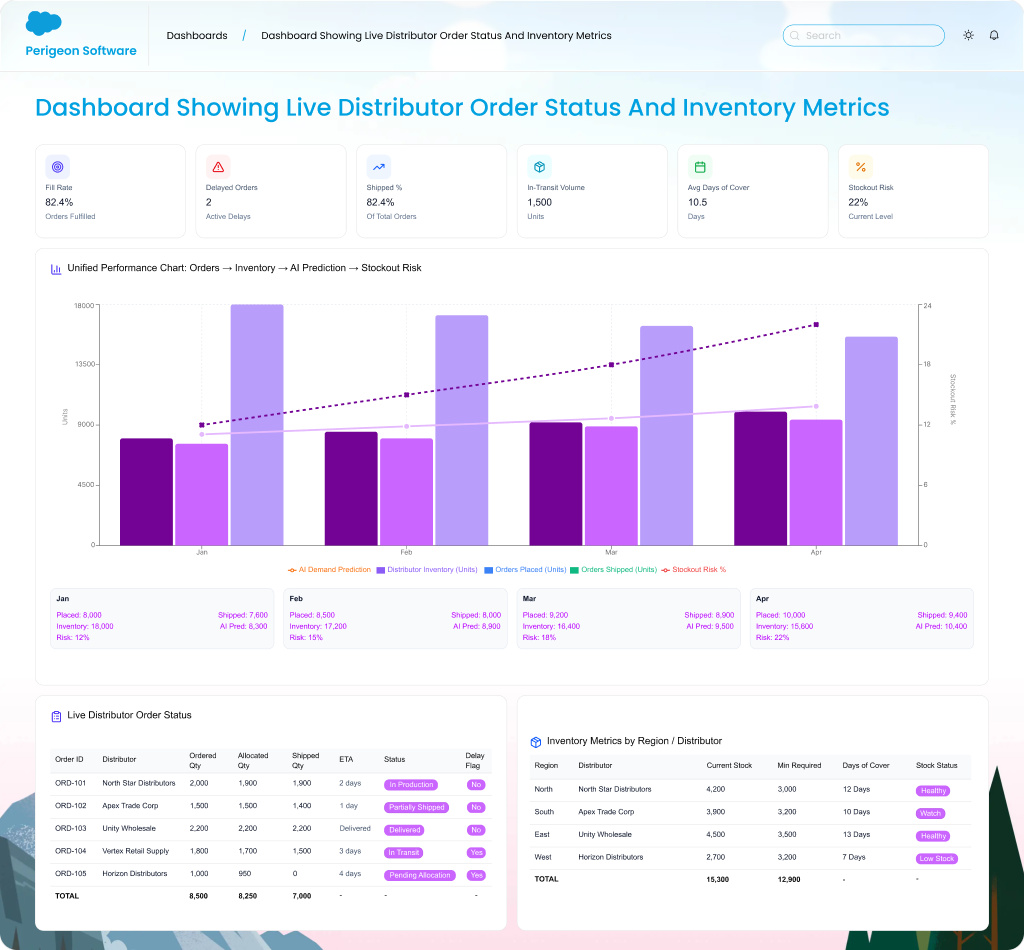

2️⃣ Real-Time Order & Inventory Visibility

Manufacturers can view distributor order pipelines and stock levels in real time.

Benefits include:

- Early visibility into potential demand surges

- Balanced replenishment planning

- Prevention of overproduction or stockouts

Dashboards powered by Salesforce Einstein Analytics provide actionable insights into channel performance, shipment delays, and product-level sales velocity.

3️⃣ Streamlined Communication Through Experience Cloud

Using Salesforce Experience Cloud, manufacturers can create secure portals for distributor engagement.

These portals enable:

- Order submission and tracking

- Access to marketing collateral and training materials

- Collaborative forecasting and feedback loops

By replacing email-based communication with structured digital workflows, information flows faster, reducing friction and misalignment.

4️⃣ Accurate Demand Forecasting Across Channels

Salesforce Einstein uses AI and predictive analytics to forecast distributor-level demand based on:

- Seasonal sales trends

- Historical order patterns

- Market and retailer data

This helps shoe manufacturers adjust production schedules, material procurement, and logistics to match real demand — improving responsiveness and efficiency.

5️⃣ Enhanced Rebate & Incentive Management

Manufacturing Cloud automates rebate tracking and incentive management, ensuring accuracy and transparency.

Distributors can view rebate eligibility and payout status directly through their portal — fostering trust and engagement.

For manufacturers, this automation means fewer manual calculations and faster reconciliation cycles.

👟 Case Example: A Global Shoe Manufacturer Streamlines Distributor Coordination

Scenario:

A leading sports shoe manufacturer working with 100+ distributors across five continents faced inconsistent demand forecasting and order duplication issues.

Challenges:

- Fragmented data across ERP and CRM systems

- Experience Cloud portals for distributors

- Einstein Analytics for predictive forecasting

Results:

- 40% improvement in forecast accuracy

- 30% reduction in order processing delays

- Rebate dispute rate dropped by 70%

- Distributor satisfaction score increased by 25%

📊 Measurable Business Impact

Manufacturers who digitize distributor collaboration with Salesforce typically achieve:

- 35% improvement in distributor engagement

- 25% faster order fulfillment

- 20% reduction in channel inventory holding costs

- 15% increase in on-time product launches

This synergy creates a more responsive, profitable, and agile distribution ecosystem.

🔮 The Future of Distributor Collaboration in Footwear Manufacturing

The next phase of distributor engagement will integrate:

- AI-driven partner performance scoring

- Automated joint business planning

- Predictive supply chain coordination

- Mobile-first collaboration apps for on-the-go order and performance tracking

These innovations will turn distributor relationships into a seamless, data-backed ecosystem that fuels growth and competitiveness.

🤝 Why Partner with Perigeon Software

Perigeon Software is a certified Salesforce Consulting Partner with proven expertise in footwear and apparel manufacturing transformation.

We help clients:

- Deploy Salesforce Manufacturing Cloud tailored to distributor networks

- Build Experience Cloud portals for real-time partner engagement

- Enable AI-driven forecasting and sales alignment

- Integrate ERP and CRM for end-to-end visibility

By partnering with Perigeon Software, footwear manufacturers unlock a connected, transparent, and growth-ready distribution model.

🏁 Conclusion

Retail forecasting in footwear manufacturing has evolved from intuition to intelligence.

Salesforce Manufacturing Cloud enables real-time collaboration, transparency, and forecasting precision — ensuring manufacturers and distributors move in lockstep toward shared growth.

With Perigeon Software as your Salesforce partner, you can modernize your distribution strategy, enhance partner trust, and take your footwear brand to the next level.