Table of content

Introduction

The Challenge of Sales & Operations Misalignment in Pulp & Paper

Why Traditional Systems Fall Short

The Salesforce Manufacturing Cloud Advantage

Real-World Example: Streamlining Alignment in a Pulp & Paper Plant

Key Benefits of Sales-Operations Integration

Why Partner with Perigeon Software

Conclusion

? Introduction

The pulp and paper manufacturing industry is the backbone of packaging, publishing, and hygiene sectors — yet it faces constant pressure to deliver cost-efficient, sustainable, and on-time production.

However, one persistent problem plagues the industry: misalignment between sales forecasts and operational realities.

Sales teams commit to large-volume orders and seasonal contracts, but without clear visibility into inventory, raw material constraints, or mill capacities, production struggles to keep up. This leads to inefficiencies, delivery delays, and missed profitability targets.

Enter Salesforce Manufacturing Cloud — a transformative solution that bridges this gap, creating seamless alignment between sales, operations, and finance teams in the pulp and paper industry.

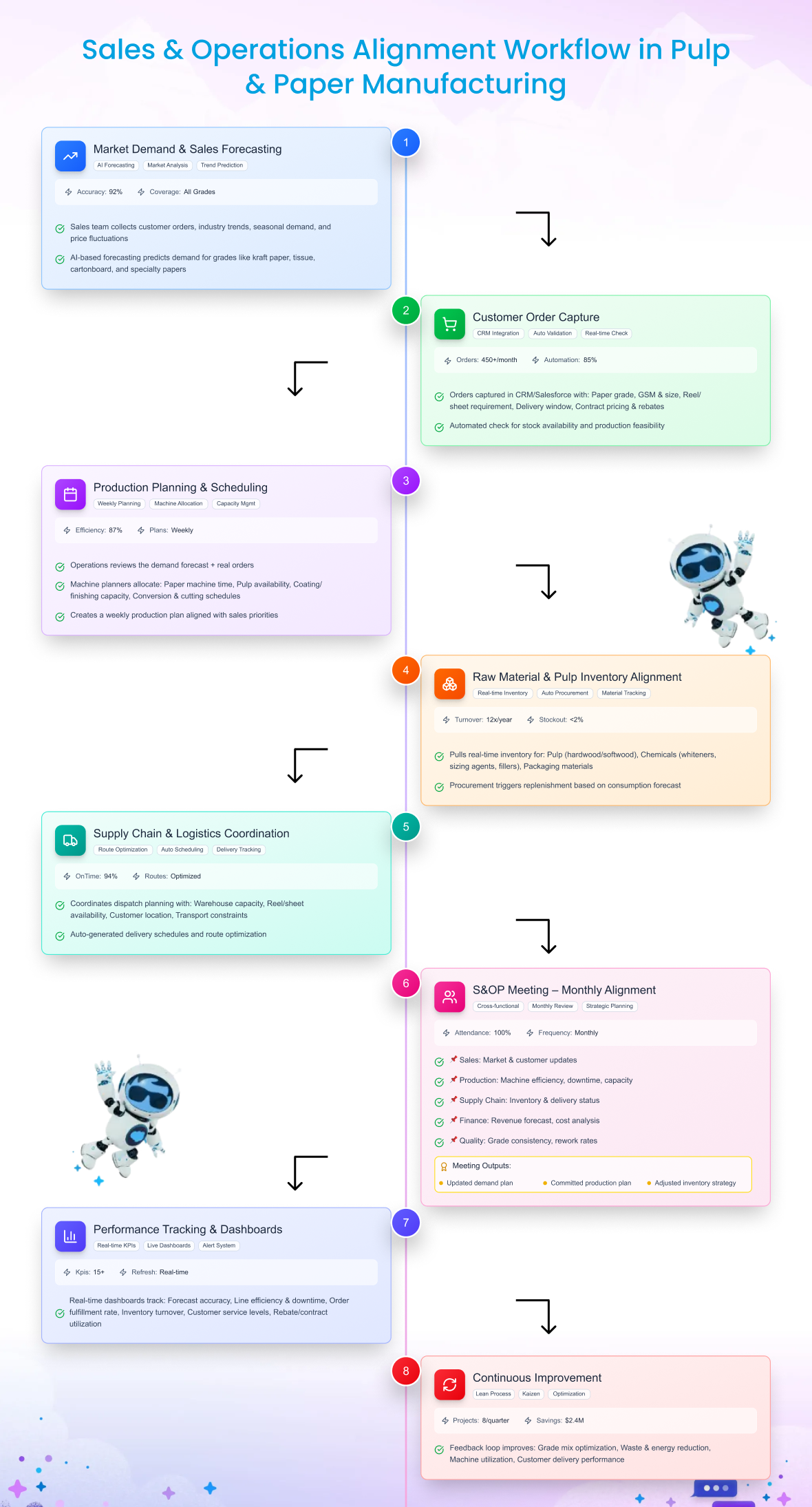

Sales & Operations Alignment Workflow in Pulp & Paper Manufacturing:A visual flow showing how Salesforce connects sales forecasting, production planning, and order fulfillment in a closed loop.

? The Challenge of Sales & Operations Misalignment in Pulp & Paper

The pulp & paper supply chain is highly capital-intensive. Mills run continuously, raw materials fluctuate in cost, and production capacity is limited.

Without synchronized forecasting and planning, common challenges include:

- Inaccurate demand forecasts leading to over- or under-production.

- Fragmented data across sales, mill operations, and procurement.

- Delayed communication between regional sales and plant scheduling.

- Inefficient inventory management due to siloed systems.

A single misstep in forecasting can cascade across the supply chain — from raw pulp sourcing to finished paper rolls — resulting in both waste and lost revenue.

⚙️ Why Traditional Systems Fall Short

Legacy ERP and spreadsheet-based systems cannot keep pace with today’s dynamic paper markets.

Key limitations include:

- Lack of real-time data: Forecasts are static and disconnected from actual demand.

- Inconsistent collaboration: Sales and operations teams work in silos.

- Limited flexibility: Systems struggle to handle new contract models and sustainability tracking.

- Manual reconciliation: Teams spend hours aligning forecasts and production reports.

This creates an information gap that prevents mills from adjusting production in real time — precisely where Salesforce Manufacturing Cloud delivers value.

? The Salesforce Manufacturing Cloud Advantage

Salesforce Manufacturing Cloud acts as a central nervous system for pulp and paper manufacturers — connecting sales, operations, and planning on one unified platform.

Let’s explore how it improves alignment end-to-end.

1️⃣ Unified Forecasting and Sales Agreements

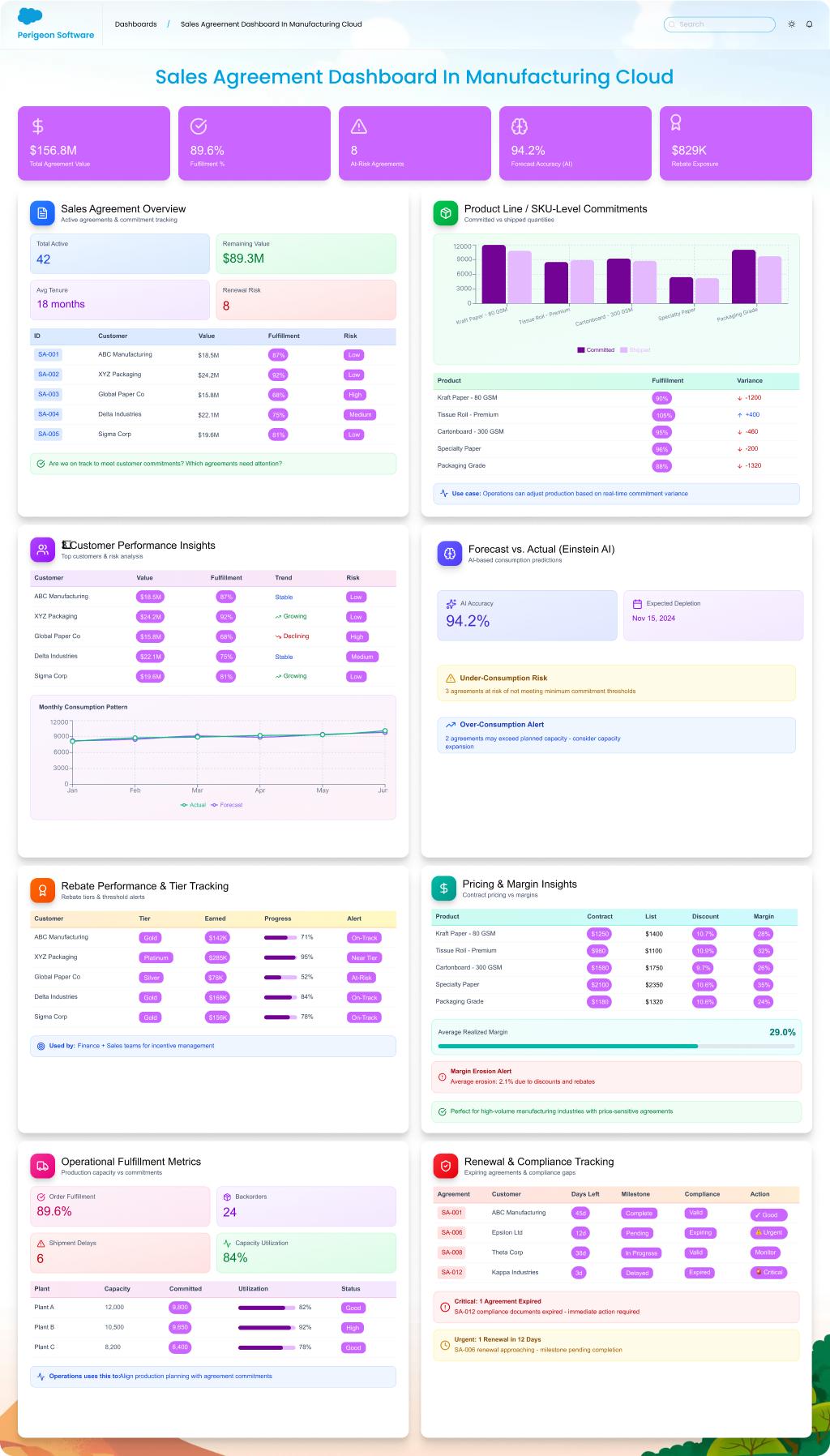

With Manufacturing Cloud’s Sales Agreements, sales and production teams share a single version of truth.

- Sales teams can create long-term contracts with dynamic pricing.

- Operations can access the same agreement data for production scheduling.

- Forecasts automatically update based on actual order performance.

Result: Production planning is proactive, not reactive. Mills can adjust schedules in real time as demand shifts.

Sales Agreement Dashboard in Manufacturing Cloud: Screenshot-style visual showing KPIs such as forecast vs. actuals, order commitments, and capacity utilization.

2️⃣ Real-Time Production Visibility

Manufacturing Cloud integrates seamlessly with ERP and mill systems to provide:

- Live production data (tonnage, downtime, and throughput).

- Real-time visibility into raw pulp, chemical usage, and machine performance.

- Automated alignment between sales demand and production output.

This helps ensure that commitments made by sales are fully feasible operationally.

Example:

If a sales team books a sudden 5,000-ton packaging paper order, Manufacturing Cloud immediately reflects whether the mill has capacity or if production must shift.

3️⃣ Data-Driven Demand Planning

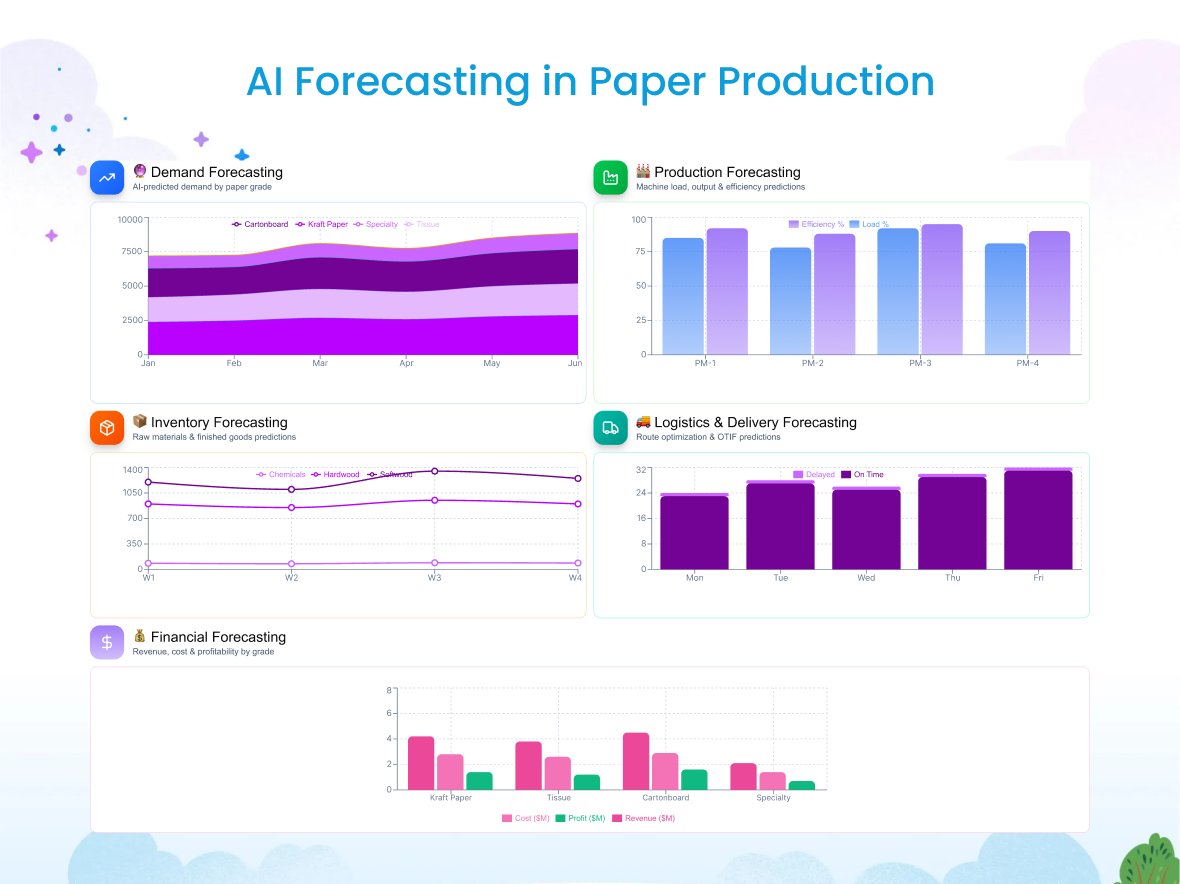

Salesforce’s Einstein AI analyzes historical data, customer demand, and seasonality to improve forecast precision.

This enables:

- Predictive inventory planning

- Optimized raw material procurement

- Reduction in unplanned downtime

Example:

A paperboard mill can forecast higher demand for eco-friendly packaging before retail season peaks — allowing them to prepare raw materials in advance.

AI Forecasting in Paper ProductionVisualization of predictive demand planning for various paper grades using Salesforce dashboards.

4️⃣ Cross-Team Collaboration Tools

Manufacturing Cloud includes collaboration portals (via Experience Cloud) for real-time communication between departments and external partners.

Benefits include:

- Shared dashboards between sales and plant managers.

- Automated alerts when forecasts or capacity plans change.

- Improved accuracy of end-to-end scheduling.

This level of transparency fosters trust and reduces end-of-quarter reconciliation delays by up to 40%.

? Real-World Example: Streamlining Alignment in a Pulp & Paper Plant

Challenge:

A major kraft paper producer struggled with disjointed forecasting — sales commitments often outpaced mill production capacity, leading to delays and stock imbalances.

Solution (implemented by Perigeon Software):

- Integrated Salesforce Manufacturing Cloud with ERP systems.

- Centralized all sales agreements and forecasts.

- Deployed AI-driven dashboards for production planning.

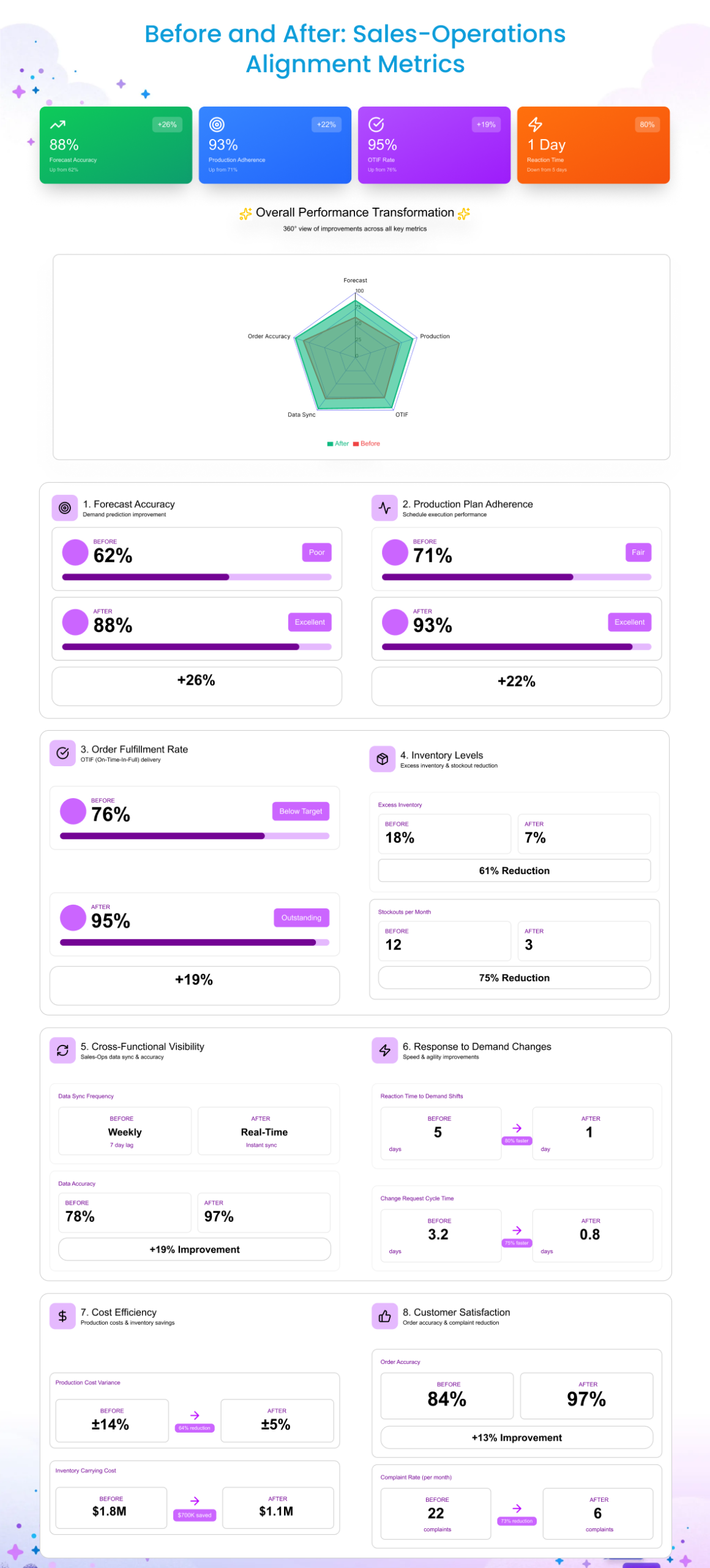

Results:

- Forecast accuracy improved by 33%.

- Production lead time reduced by 25%.

- On-time delivery improved by 40%.

- Customer satisfaction scores rose by 18% within 6 months.

? Key Benefits of Sales-Operations Integration

Business AreaImpactForecast Accuracy+30% precision in demand planningProduction Efficiency-25% downtime and scheduling conflictsCustomer Service+40% on-time delivery improvementProfitability+12% overall margin growthSustainabilityReduced waste and optimized raw pulp use

Before and After: Sales-Operations Alignment Metrics:A comparative infographic showing improvements in forecast accuracy and production efficiency.

? Why Partner with Perigeon Software

At Perigeon Software, we help pulp and paper manufacturers unlock the full potential of Salesforce Manufacturing Cloud through:

- End-to-end implementation and configuration

- Custom dashboards for mill operations and demand planning

- Integration with ERP and production tracking systems

- Partner collaboration portals

- AI-driven forecasting solutions

We don’t just deploy Salesforce — we tailor it for your specific mill operations, production lines, and distribution networks.

With Perigeon, you gain a partner who understands both manufacturing logic and digital transformation strategy.

? Conclusion

For pulp and paper manufacturers, aligning sales and operations isn’t just about efficiency — it’s about competitiveness.

Salesforce Manufacturing Cloud bridges the traditional divide between forecasting and production, ensuring every sales promise is operationally achievable and financially optimized.

Perigeon Software empowers you to realize that alignment — improving communication, boosting transparency, and driving long-term profitability across your entire manufacturing ecosystem.