Table of content

Introduction

Why Distributor Networks Are Critical in Cement Manufacturing

Key Challenges in Distributor-Heavy Cement Models

How Salesforce Manufacturing Cloud Strengthens Distributor Management

Case Study: Cement OEM Transforms Distributor Operations

The Future of Distributor Management in Cement

Conclusion

Introduction

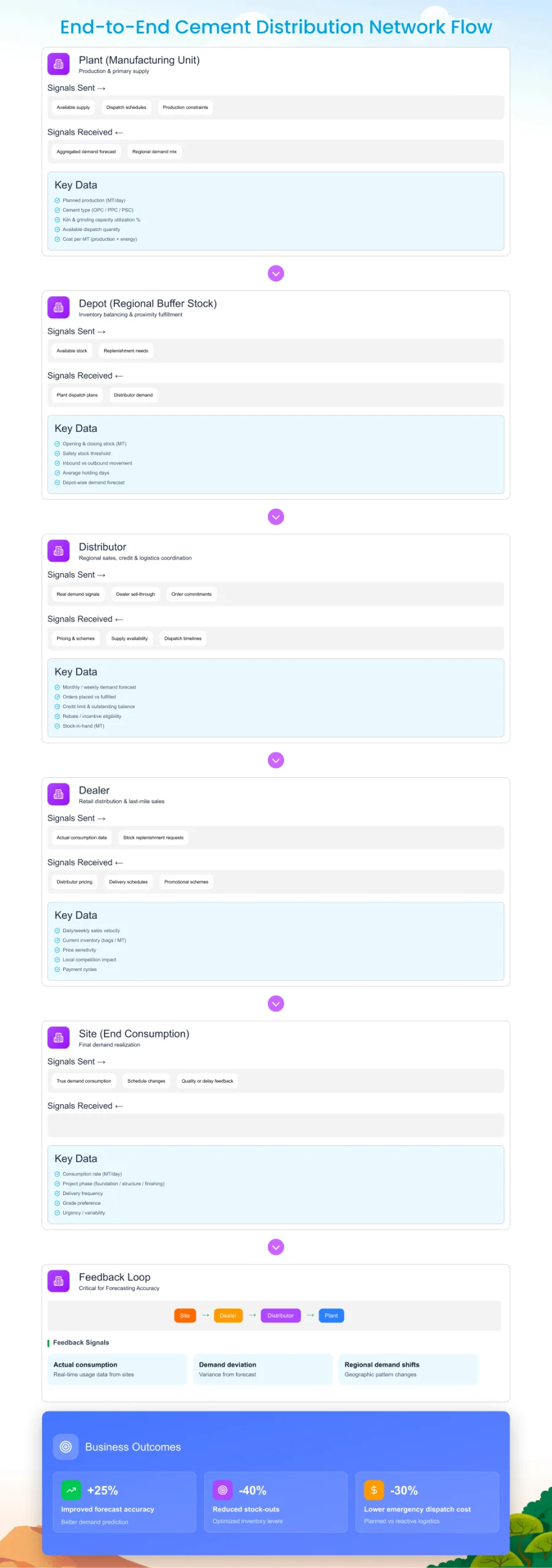

Cement is sold and delivered through large, geographically dispersed distributor networks. These distributors manage regional sales, dealer relationships, credit, and last-mile delivery — making them indispensable but complex to manage.

According to PwC (2024), over 60% of cement manufacturers cite distributor opacity as the biggest cause of demand–supply mismatch. Without real-time collaboration, manufacturers face stock imbalances, emergency dispatches, and margin erosion.

Salesforce Manufacturing Cloud provides a unified platform to digitize distributor collaboration, automate incentives, and align demand with production and dispatch.

Why Distributor Networks Are Critical in Cement Manufacturing

- Regional Market Access → Distributors understand local demand and pricing

- Credit & Collections → Manage receivables and dealer financing

- Logistics Coordination → Plan truck, rail, and depot movements

- Market Intelligence → Feed real consumption data back to OEMs

👉 Strong distributor management directly impacts market share and profitability.

Key Challenges in Distributor-Heavy Cement Models

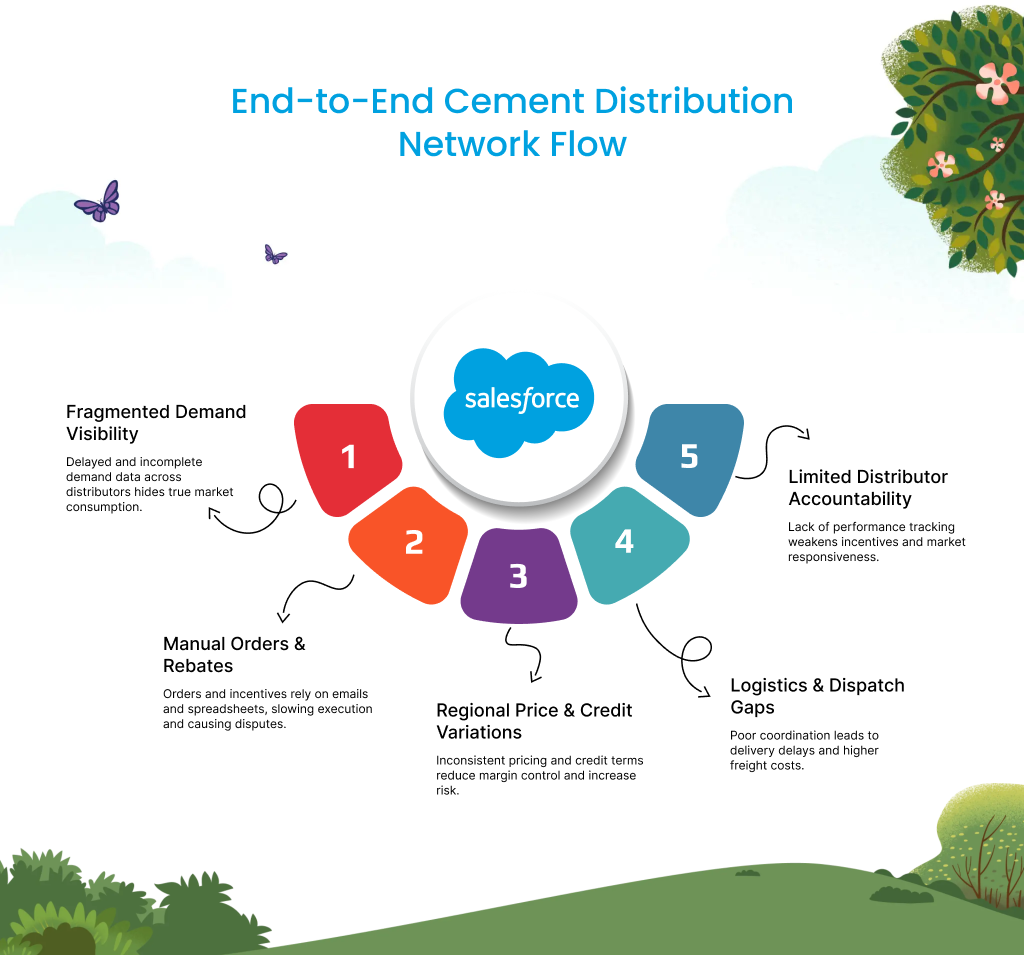

1. Fragmented Demand Visibility

- OEMs rely on delayed distributor reports

- Real consumption patterns remain hidden

2. Manual Order & Rebate Processes

- Orders placed via calls and emails

- Rebate claims tracked in spreadsheets

3. Regional Price & Credit Variations

- Pricing and credit terms vary by region

- Difficult to enforce consistency

4. Logistics & Dispatch Coordination Issues

- Poor alignment between distributor orders and plant dispatch

- Emergency freight inflates costs

5. Limited Distributor Accountability

- No real-time performance tracking

- Difficult to link incentives to actual outcomes

How Salesforce Manufacturing Cloud Strengthens Distributor Management

1. Distributor Collaboration Portals

- Experience Cloud portals allow distributors to:

- Place and track orders

- Update forecasts

- View rebates, credit limits, and agreements

2. Real-Time Demand & Inventory Visibility

- OEMs gain live visibility into distributor stock levels

- Track regional sales velocity

- Improves plant and depot planning

3. Automated Rebates, Incentives & Claims

- Configures region-specific incentive programs

- Automates eligibility, calculation, and approvals

- Reduces disputes and processing delays

4. ERP & Logistics Integration

- Syncs Salesforce with ERP and transport systems

- Aligns production, dispatch, and invoicing seamlessly

5. AI-Powered Distributor Performance Insights

- Einstein AI identifies underperforming distributors

- Detects credit risk patterns

- Highlights high-growth regions needing capacity support

Case Study: Cement OEM Transforms Distributor Operations

A cement manufacturer managing 800+ distributors across multiple states faced:

- Frequent stockouts in high-demand regions

- Delayed rebate settlements

After Salesforce Manufacturing Cloud:

- Distributor forecast accuracy improved by 24%

- Emergency dispatch costs reduced by 18%

- Rebate disputes dropped by 60%

The Future of Distributor Management in Cement

- AI-Driven Distributor Scoring Models

- Blockchain-Based Dispatch & Invoice Validation

- Mobile-First Distributor Apps

- Carbon-Aware Logistics Optimization

Conclusion

Distributor networks are a strategic advantage — when managed digitally. Salesforce Manufacturing Cloud enables cement manufacturers to:

- Collaborate with distributors in real time

- Automate rebates and incentives

- Align dispatch with real demand

- Use AI to optimize regional performance

With Salesforce, distributor-heavy networks become predictable, transparent, and scalable.

🚚 Ready to modernize your cement distributor network?

👉 Book a Manufacturing Cloud Strategy Session with Perigeon