Table of content

Introduction

The Wood & Furniture Manufacturing Landscape

Why Forecast Accuracy Matters in Furniture Manufacturing

Key Forecasting Challenges in the Furniture Industry

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

Case Study: Furniture Manufacturer Improves Forecast Reliability

The Future of Forecasting in Wood & Furniture Manufacturing

Conclusion

Introduction

The wood and furniture manufacturing industry sits at the intersection of craftsmanship, design trends, and industrial-scale production. From residential and office furniture to modular kitchens and bespoke interiors, manufacturers must balance aesthetic variety with operational precision.

Yet forecasting demand in furniture manufacturing is notoriously difficult. Consumer preferences change quickly, customization is high, and demand is often driven by dealers, large projects, and real-estate cycles rather than steady replenishment models.

Industry studies consistently show that forecast inaccuracies of 25–35% are common in furniture manufacturing—resulting in excess raw material inventory, delayed deliveries, or missed sales opportunities.

Salesforce Manufacturing Cloud helps furniture manufacturers improve forecast accuracy by aligning sales agreements, dealer inputs, production capacity, and AI-driven insights into a single, connected planning platform.

The Wood & Furniture Manufacturing Landscape

Product Categories

- Residential furniture (beds, sofas, dining, wardrobes)

- Office and commercial furniture

- Modular and customized furniture

- Engineered wood products and panels

Sales Models

- Dealer- and distributor-led retail

- Project-based sales (commercial, hospitality, real estate)

- Direct-to-consumer (increasing but still limited)

Production Characteristics

- Mix of make-to-stock and make-to-order

- Long lead times for finishing, polishing, and upholstery

- Dependency on wood, boards, laminates, foams, and fabrics

👉 In this environment, forecast accuracy directly determines delivery reliability, working capital efficiency, and margins.

Why Forecast Accuracy Matters in Furniture Manufacturing

- Raw Material Optimization: Poor forecasts lead to overbuying or production delays.

- Production Capacity Planning: Carpentry, finishing, and upholstery lines require stable scheduling.

- Dealer & Project Commitments: Late or inaccurate deliveries damage dealer trust and brand reputation.

- Inventory & Warehouse Costs: Bulky finished goods are expensive to store and transport.

- Margin Protection: Rush production and expedited logistics erode already-thin margins.

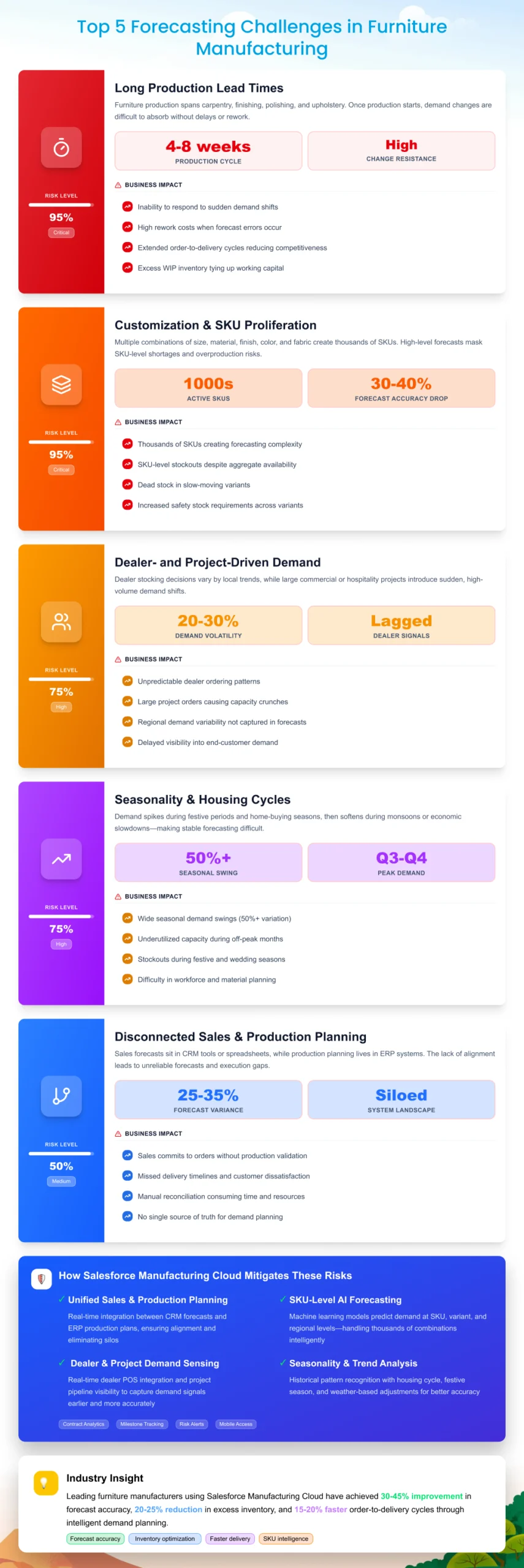

Key Forecasting Challenges in the Furniture Industry

1. Long Production Lead Times

- Furniture manufacturing involves multiple sequential processes

- Demand changes mid-cycle are hard to accommodate

2. Customization & SKU Proliferation

- Size, material, finish, color, and upholstery combinations explode SKU counts

- Aggregate forecasting hides SKU-level risk

3. Dealer- and Project-Driven Demand

- Dealers stock based on local trends

- Large commercial projects skew demand suddenly

4. Seasonality & Housing Cycles

- Demand peaks during festive and home-buying seasons

- Slows during monsoons or economic uncertainty

5. Disconnected Sales and Production Planning

- Sales forecasts live in CRM or spreadsheets

- Production plans live in ERP or manual tools

- No shared ownership of forecast accuracy

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

1. Account- & Project-Based Forecasting

- Forecast demand by dealer, retail chain, or commercial project

- Improves accountability and precision versus top-down forecasts

2. Sales Agreement–Driven Demand Commitments

- Converts dealer agreements and project contracts into committed demand signals

- Separates firm demand from speculative pipeline forecasts

3. Dealer & Retailer Forecast Collaboration

- Dealers update forecasts via collaboration portals

- Manufacturers gain near real-time market visibility

4. ERP & Production Planning Integration

- Integrates Salesforce forecasts with ERP/MRP systems

- Aligns carpentry, finishing, and upholstery schedules with real demand

5. AI-Powered Demand Sensing & Risk Alerts

- Analyzes historical sales, dealer behavior, seasonality, and housing trends

- Flags overproduction risks, delivery risks, and bottlenecks early

Case Study: Furniture Manufacturer Improves Forecast Reliability

A mid-sized furniture manufacturer faced:

- Frequent order rescheduling

- Overstock of slow-moving designs

- Missed delivery dates for custom orders

After implementing Salesforce Manufacturing Cloud:

- Forecast accuracy improved by 28%

- Finished goods inventory reduced by 20%

- On-time delivery improved significantly

The Future of Forecasting in Wood & Furniture Manufacturing

- AI-Driven Design Trend Forecasting

- Project Pipeline–Based Demand Models linked to real-estate data

- IoT-Enabled Shopfloor Feedback for real-time capacity updates

- Sustainability-Aware Forecasting for certified wood and eco-materials

Conclusion

In furniture manufacturing, forecast accuracy is not just a planning metric—it is a competitive advantage.

- Forecast demand at dealer, project, and SKU level

- Align sales commitments with production reality

- Reduce inventory waste and delivery risk

- Use AI to anticipate demand shifts early

With Salesforce, furniture manufacturers move from reactive guesswork to predictable, data-driven execution.

🎯 Ready to improve forecast accuracy in furniture manufacturing?

👉 Book a Manufacturing Cloud Strategy Session with Perigeon