Table of content

Introduction

Demand–Supply Complexity in Wood Products Manufacturing

Key Demand–Supply Planning Challenges

How Salesforce Manufacturing Cloud Streamlines Planning

Case Study: Wood Products Manufacturer Improves Planning Accuracy

The Future of Demand–Supply Planning in Wood Manufacturing

Conclusion

Introduction

Wood products manufacturing depends on tight coordination between demand planning and raw material availability. Timber sourcing, seasoning, and processing timelines leave little room for error.

Studies indicate that ineffective demand–supply alignment causes up to 18% material waste in wood manufacturing—driving up costs and sustainability risks.

Salesforce Manufacturing Cloud brings demand and supply together—connecting sales forecasts, contracts, procurement, and production planning into a single, AI-driven system.

Demand–Supply Complexity in Wood Products Manufacturing

- Inputs → Timber, resins, chemicals

- Processes → Drying, pressing, finishing

- Outputs → Boards, panels, customized cuts

- Markets → Furniture OEMs, construction, exports

👉 Any mismatch leads to raw material spoilage, capacity underutilization, or delayed deliveries.

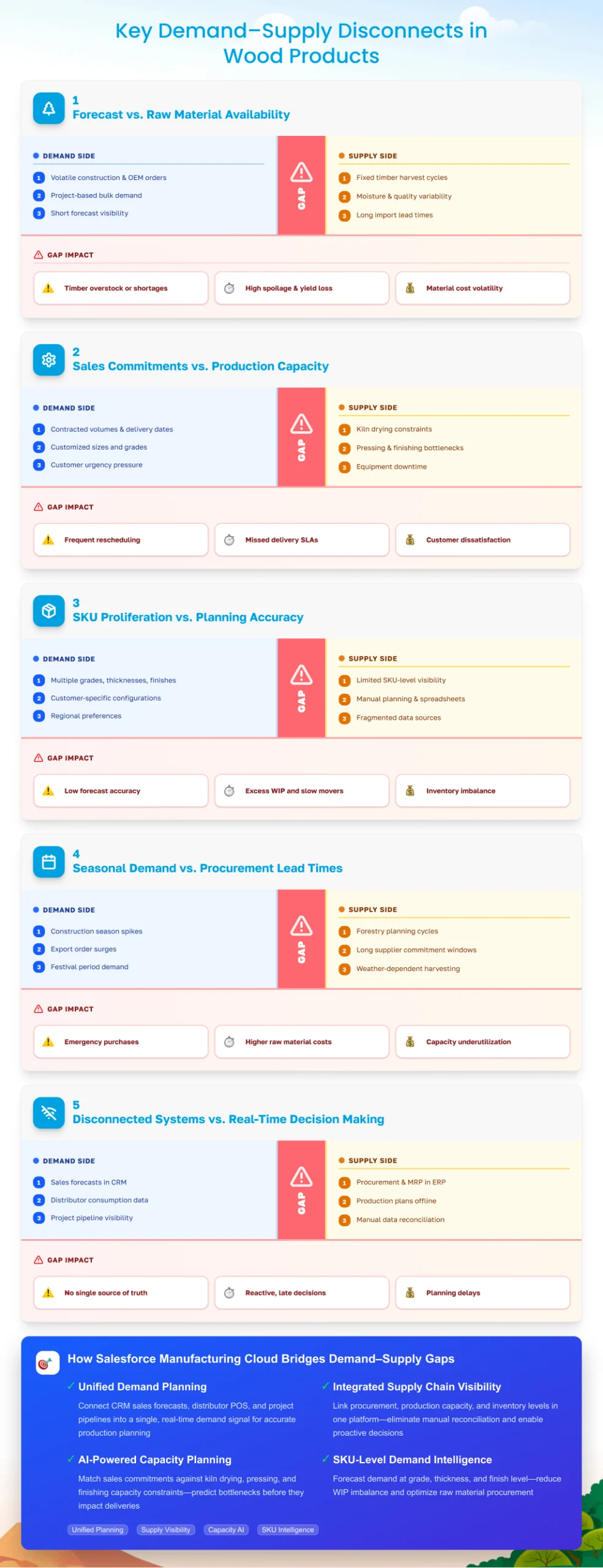

Key Demand–Supply Planning Challenges

1. Raw Material Variability

- Timber quality and moisture levels vary

- Impacts yield and production scheduling

2. Long Procurement Lead Times

- Forestry and imports require advance planning

- Limited flexibility once orders are placed

3. SKU & Grade Proliferation

- Thickness, grade, finish, and size variations multiply complexity

- Increases planning and inventory challenges

4. Seasonal & Project-Based Demand

- Construction cycles create sudden volume shifts

- Demand spikes strain capacity planning

5. Disconnected Planning Systems

- Sales in CRM, procurement in ERP, planning in spreadsheets

- Lack of unified demand–supply visibility

How Salesforce Manufacturing Cloud Streamlines Planning

1. Unified Demand & Supply Visibility

- Single view of forecasts, orders, and capacity

- Shared ownership across sales, procurement, and operations

2. Contract- & Forecast-Driven Material Planning

- Converts confirmed demand into raw material signals

- Reduces speculative buying and excess stock

3. Supplier & Distributor Collaboration

- Suppliers receive forecast visibility

- Distributors share real consumption trends

4. ERP & MRP Synchronization

- Aligns Salesforce demand with ERP material plans

- Improves production scheduling accuracy

5. AI-Powered Risk & Shortage Prediction

- Flags material shortages early

- Identifies capacity bottlenecks

- Detects demand spikes proactively

Case Study: Wood Products Manufacturer Improves Planning Accuracy

A panel board manufacturer supplying furniture OEMs and builders faced:

- Overstocked raw timber

- Frequent production rescheduling

After implementing Salesforce Manufacturing Cloud:

- Material planning accuracy improved by 23%

- Waste reduced by 15%

- On-time delivery improved across major customers

The Future of Demand–Supply Planning in Wood Manufacturing

- AI Yield Optimization Models

- Digital Twin Mills for capacity simulation

- Sustainability-Driven Planning (FSC-certified sourcing)

- Real-Time Supplier Risk Scoring

Conclusion

Demand–supply alignment is the backbone of efficient wood manufacturing. Salesforce Manufacturing Cloud enables manufacturers to:

- Synchronize demand with raw material planning

- Reduce waste and working capital

- Improve delivery reliability

- Leverage AI for proactive decision-making

🌲 Ready to streamline demand–supply planning in wood products?

👉 Book a Manufacturing Cloud Strategy Session with Perigeon