Table of content

Introduction

Why Forecast Alignment Is a Challenge in Rubber Manufacturing

The Cost of Poor Forecast Accuracy

How Salesforce Manufacturing Cloud Bridges the Gap

Real-World Example: Forecast Alignment in Action

Benefits of Forecast Synchronization

Why Partner with Perigeon Software

Conclusion

? Introduction

For rubber product manufacturers, balancing production schedules with fluctuating customer demand is one of the biggest operational challenges.

From automotive components and industrial hoses to tires and molded parts — production cycles are long, materials are costly, and customer orders can shift rapidly due to economic or seasonal changes.

Without proper synchronization between sales forecasts and production planning, manufacturers face either overproduction (tying up capital) or stockouts (losing orders).

That’s where Salesforce Manufacturing Cloud becomes a game changer — offering a unified platform to align demand forecasts from sales teams with production plans on the shop floor.

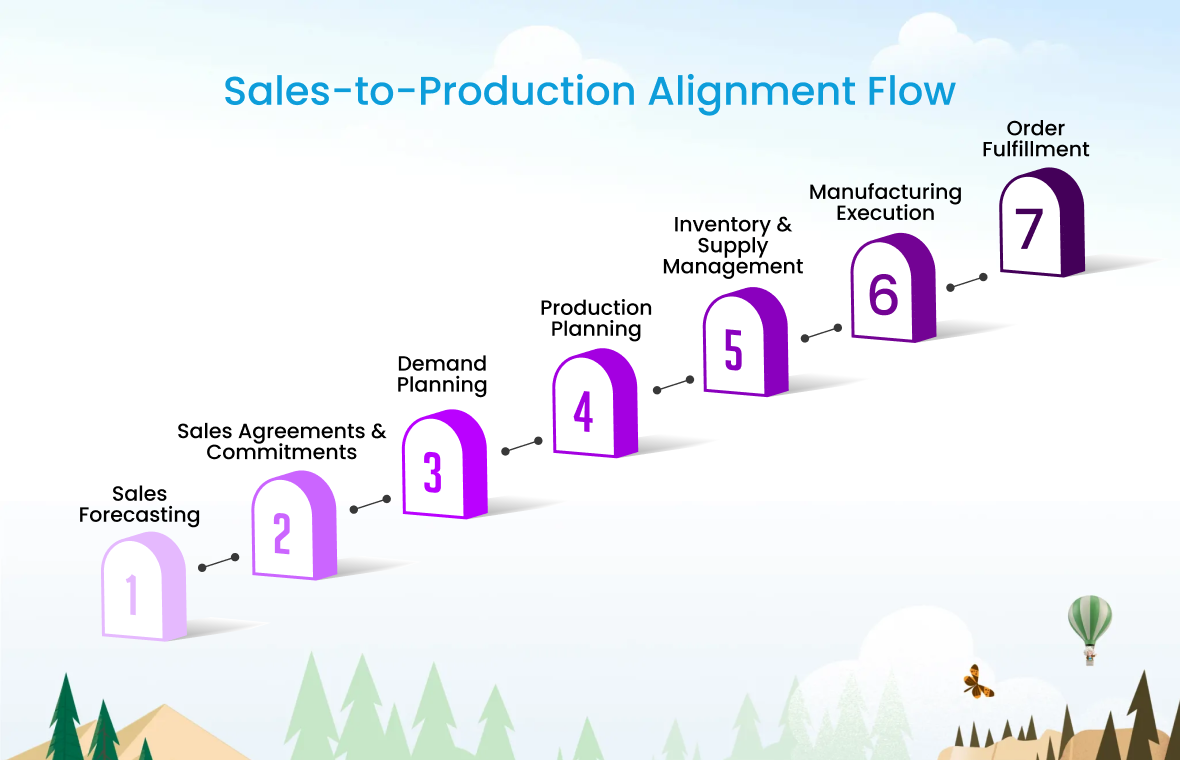

Sales-to-Production Alignment Flow: Diagram showing how Salesforce Manufacturing Cloud connects sales forecasting, production planning, and inventory data.

⚙️ Why Forecast Alignment Is a Challenge in Rubber Manufacturing

Rubber manufacturing relies heavily on batch production and compound formulation, both of which require precise planning.

However, most manufacturers still operate with disconnected systems — where the sales team’s forecast lives in spreadsheets, and the production plan resides in ERP.

This disconnect leads to:

- Inaccurate visibility into future demand.

- Production bottlenecks or idle capacity.

- Material wastage due to wrong batch quantities.

- Inconsistent inventory levels across SKUs.

Result: missed delivery deadlines, customer dissatisfaction, and reduced profitability.

? The Cost of Poor Forecast Accuracy

Forecast inaccuracy in rubber manufacturing directly affects the bottom line:

Impact AreaBusiness EffectOverproductionExcess inventory, higher carrying costsUnderproductionLost sales, delayed shipmentsRaw Material WasteInefficient batch productionWorkforce UtilizationUnderused or overworked production lines

The Cost of Poor Forecast Accuracy

Forecast inaccuracy in rubber manufacturing directly affects the bottom line:

| Impact Area | Business Effect |

|---|---|

| Overproduction | Excess inventory, higher carrying costs |

| Underproduction | Lost sales, delayed shipments |

| Raw Material Waste | Inefficient batch production |

| Workforce Utilization | Underused or overworked production lines |

? How Salesforce Manufacturing Cloud Bridges the Gap

Salesforce Manufacturing Cloud acts as the single source of truth for both demand and production data — connecting sales commitments, customer agreements, and real-time performance metrics to improve planning accuracy.

Here’s how:

1️⃣ Unified Sales & Operations Data

Manufacturing Cloud integrates sales forecasts, historical data, and customer order trends into one collaborative workspace.

Production teams can access this data instantly to:

- Adjust capacity planning.

- Optimize batch scheduling.

- Predict raw material requirements.

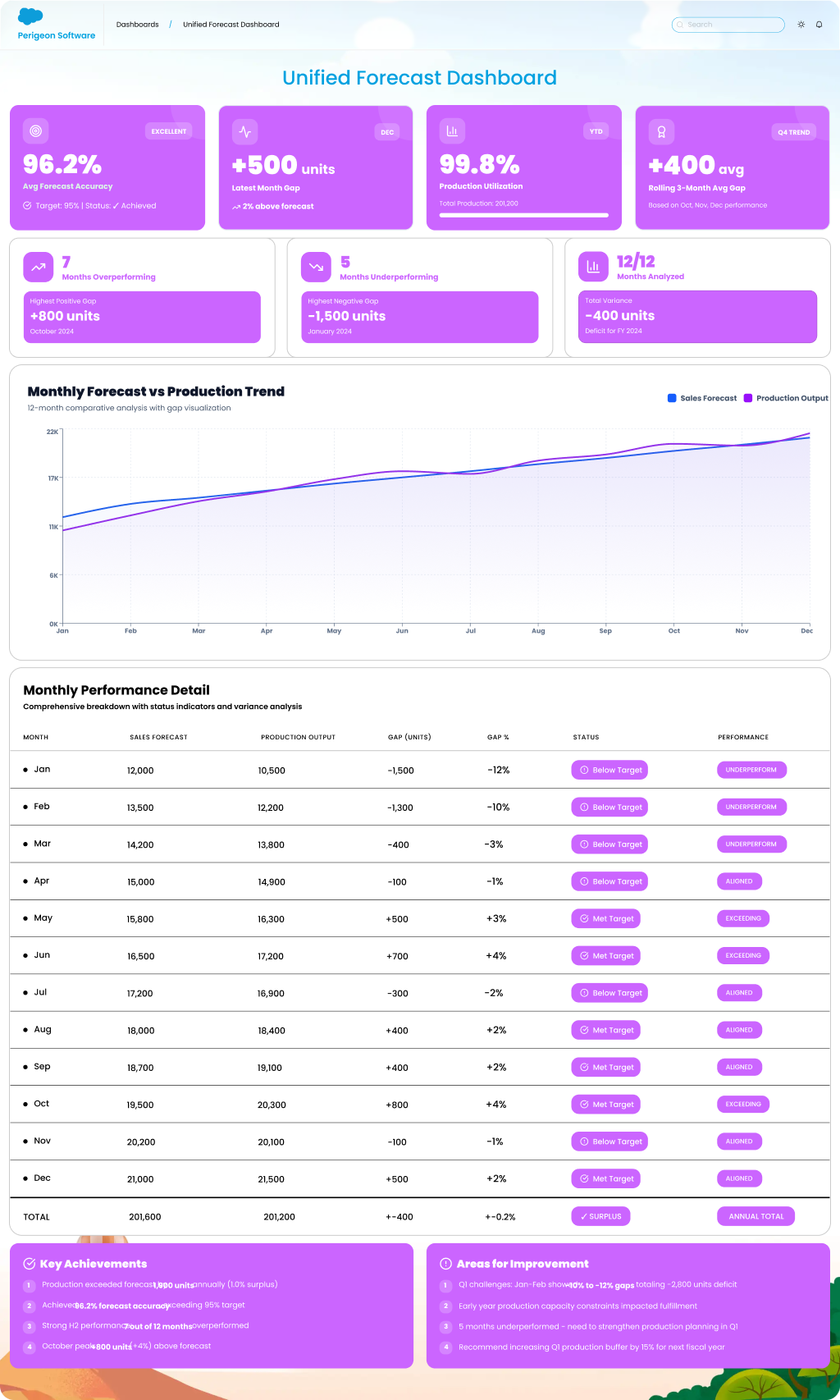

Unified Forecast Dashboard: Salesforce dashboard showing live sales forecasts vs. production output trends.

2️⃣ Real-Time Forecast Adjustments

When sales teams update forecasts or customers modify orders, Manufacturing Cloud automatically reflects these changes in the production pipeline.

This ensures production managers can:

- React quickly to new demand signals.

- Reallocate capacity across plants.

- Avoid overproduction and material waste.

Example:

If an automotive customer increases its monthly demand for rubber gaskets, the production team instantly receives visibility of the change — ensuring on-time fulfillment without last-minute scrambling.

3️⃣ Collaboration Between Sales, Planning & Finance

Manufacturing Cloud enhances collaboration by connecting all stakeholders:

- Sales teams input forecasts and agreements.

- Production planners align capacity and batch schedules.

- Finance validates profitability and resource utilization.

This real-time collaboration replaces the need for email chains or manual report sharing — allowing every department to work from the same trusted data.

4️⃣ Intelligent Analytics for Continuous Optimization

Using Salesforce’s Einstein Analytics, manufacturers can identify forecast trends, seasonal variations, and customer behavior patterns.

Predictive insights help teams:

- Identify forecast bias (over- or under-forecasting).

- Simulate “what-if” scenarios for new contracts.

- Continuously improve production accuracy based on outcomes.

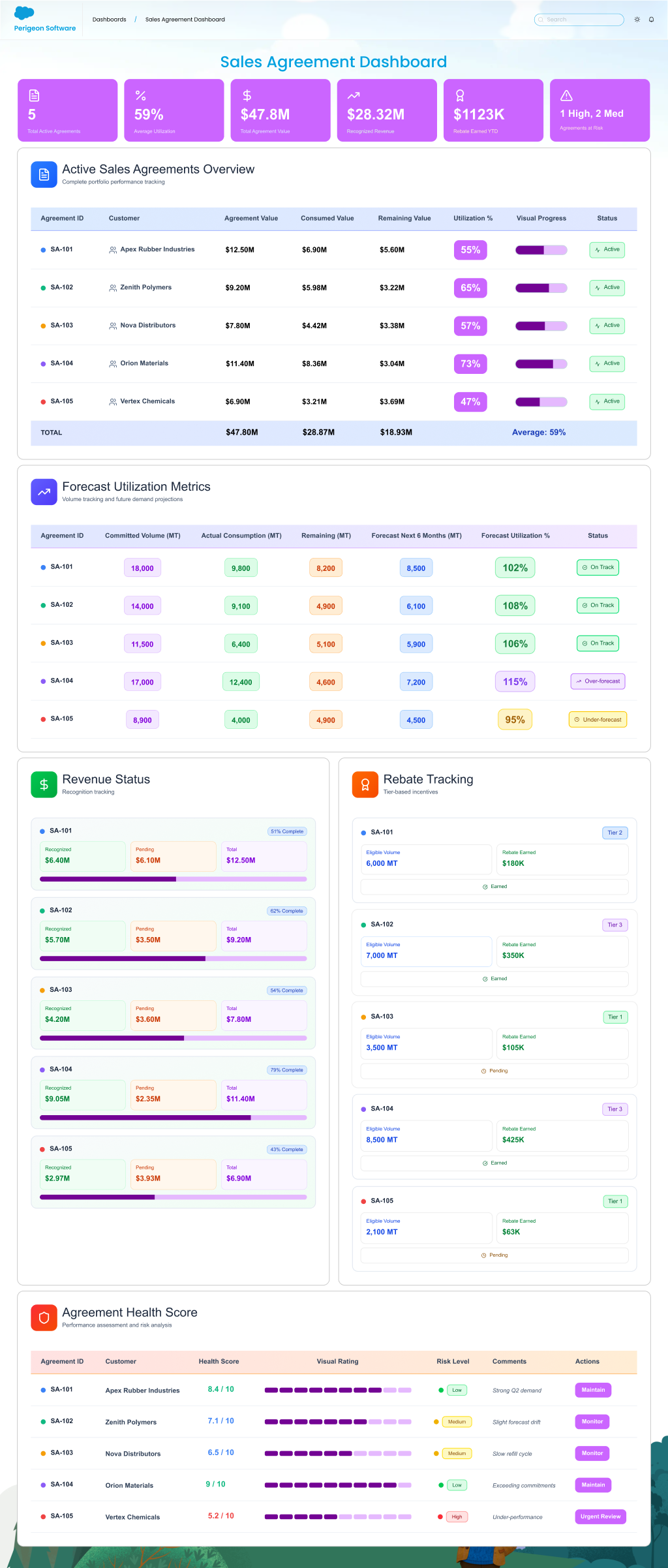

AI Forecast Insights: Visual of predictive analytics dashboard showing forecast accuracy and variance metrics.

? Real-World Example: Forecast Alignment in Action

Scenario:

A leading industrial rubber components manufacturer faced frequent misalignment between sales forecasts and production schedules. Overproduction of some SKUs caused warehouse congestion, while others faced delivery delays.

Perigeon Software Solution:

- Implemented Salesforce Manufacturing Cloud with real-time sales agreement tracking.

- Integrated the platform with SAP ERP for synchronized capacity planning.

- Built predictive forecasting dashboards using Einstein Analytics.

Results:

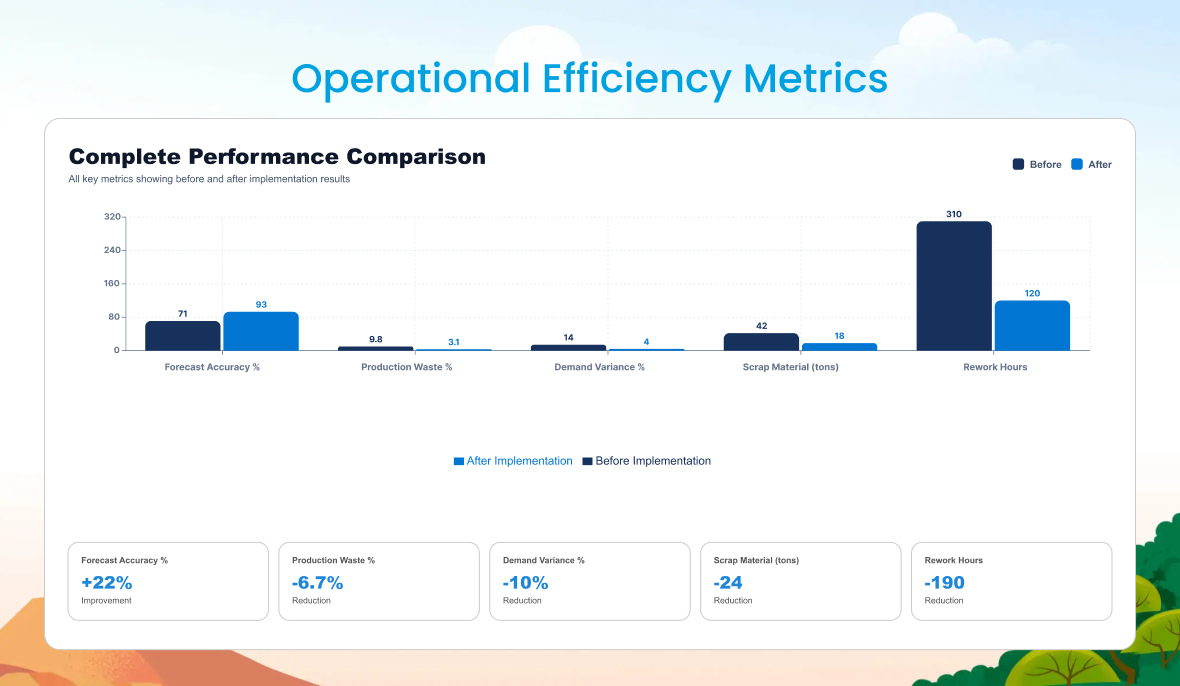

- Forecast accuracy improved by 42%.

- Raw material waste reduced by 28%.

- Customer on-time delivery increased to 97%.

? Benefits of Forecast Synchronization

Benefit AreaResultForecast Accuracy+40–50% improvementProduction EfficiencyOptimized batch utilizationWaste Reduction-25–30% material wasteCustomer Satisfaction95%+ on-time deliveryProfitabilityBetter cost control & margin protection

Financial Accuracy Metrics: Chart showing pre- vs. post-Salesforce implementation improvements in revenue variance and rebate time.

? Key Benefits for Rubber Manufacturers

The Cost of Poor Forecast Accuracy

Forecast inaccuracy in rubber manufacturing directly affects the bottom line:

Benefits of Forecast Synchronization

| Benefit Area | Result |

|---|---|

| Forecast Accuracy | +40–50% improvement |

| Production Efficiency | Optimized batch utilization |

| Waste Reduction | −25–30% material waste |

| Customer Satisfaction | 95%+ on-time delivery |

| Profitability | Better cost control & margin protection |

? Why Partner with Perigeon Software

At Perigeon Software, we specialize in transforming manufacturing operations with Salesforce solutions designed for forecast alignment, contract visibility, and operational agility.

Our expertise includes:

- Custom Manufacturing Cloud implementations for rubber & polymer industries.

- Integration with ERP and production systems.

- AI-driven demand planning and performance dashboards.

- Process automation for real-time production insight.

We don’t just deploy Salesforce — we align it with your business goals for measurable results.

? Conclusion

Aligning demand forecasts with production planning isn’t just a technical upgrade — it’s a strategic transformation.

With Salesforce Manufacturing Cloud, rubber manufacturers gain:

- End-to-end visibility across sales, production, and finance.

- Improved forecast accuracy.

- Reduced waste and improved delivery performance.

Perigeon Software ensures your teams work in harmony — transforming data alignment into operational excellence.