Table of content

Introduction

Why Efficiency Is a Core Challenge in Steel Manufacturing

The Cost of Fragmented Systems in the Steel Industry

How Salesforce Manufacturing Cloud Drives End-to-End Efficiency

Industry Case Example: Steel Manufacturer Transformation

Key Business Outcomes for Steel Manufacturers

Why Partner with Perigeon Software

Conclusion

1.Introduction

Steel manufacturing is one of the world’s most vital industries—feeding construction, automotive, infrastructure, aerospace, energy, and heavy machinery. But it also remains one of the most complex, plagued by:

- Volatile raw material costs

- Long production cycles

- Capacity constraints

- High energy consumption

- Contract-driven sales

- Multi-tier distributor networks

The result? Inefficiency that affects margins, delivery timelines, and customer relationships.

Salesforce Manufacturing Cloud helps steel manufacturers modernize by aligning sales, production, demand forecasting, and partner collaboration under one integrated digital platform.

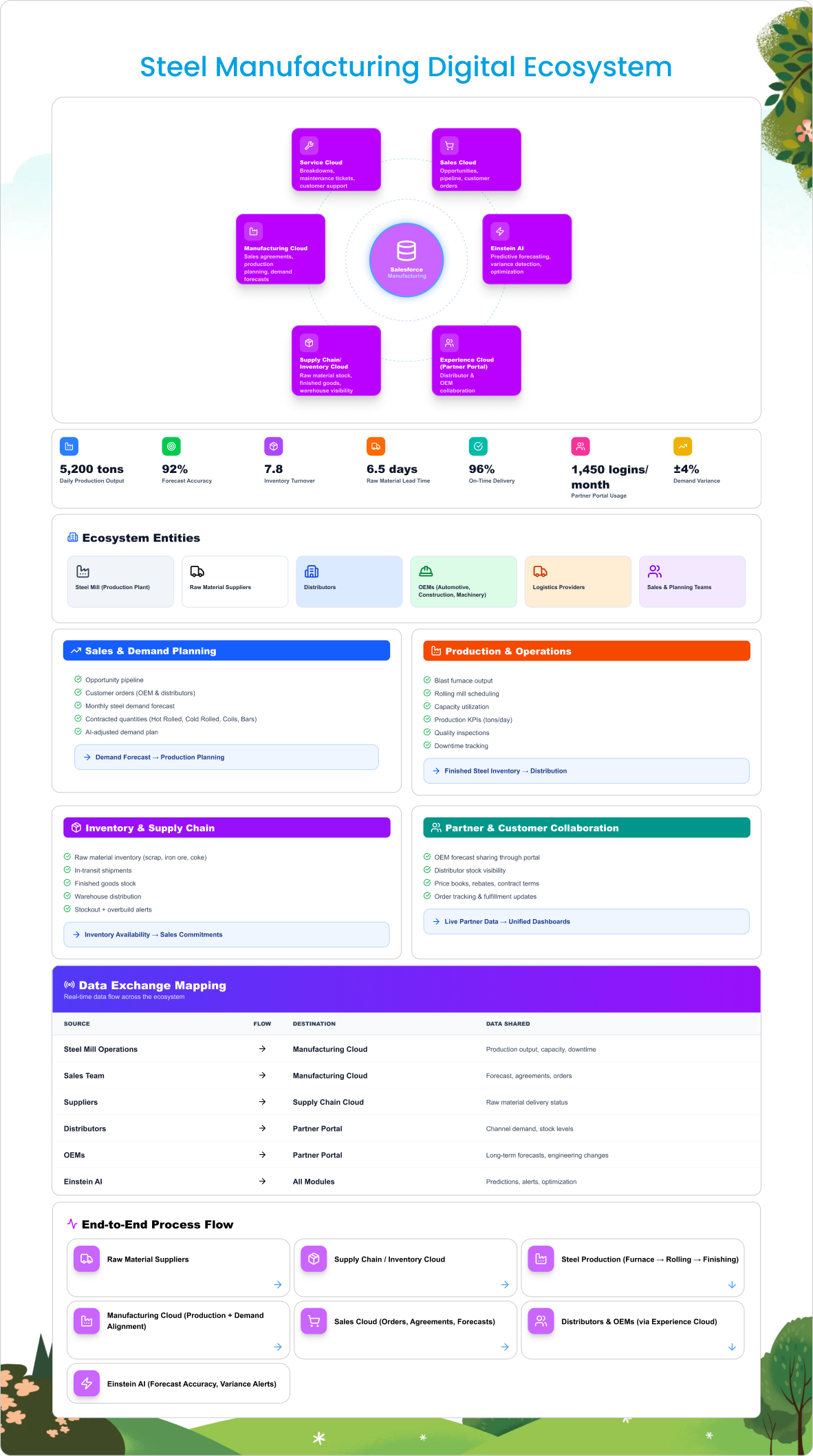

Steel Manufacturing Digital Ecosystem: A visual showing steel production, sales, and forecasting connected through Salesforce cloud modules.

2.Why Efficiency Is a Core Challenge in Steel Manufacturing

The steel industry operates on tight margins. Even small inefficiencies can result in massive financial loss.

Here’s what makes efficiency difficult:

✔ Long and rigid production cycles

Casting, rolling, heat treatment, and finishing take days to weeks.

✔ Highly volatile input prices

Iron ore, scrap metal, coking coal, electricity, and gas prices change daily.

✔ Large-scale batch production

Any mismatch between demand and production leads to either stockpiles or shortages.

✔ Contract-heavy business model

OEMs, EPCs, and distributors often rely on multi-year agreements with volume commitments.

✔ Complex supply chain dependencies

Transportation, export documentation, and quality approvals add further delays.

All of this makes efficiency a strategic differentiator, not just an operational goal.

3.The Cost of Fragmented Systems in the Steel Industry

Most steel manufacturers still manage operations through ERP-heavy environments, spreadsheets, email-based collaboration, and siloed data systems.

This fragmentation leads to:

❌ Poor sales-to-production alignment

Sales commits volumes without visibility into plant capacity.

❌ Incorrect or outdated forecasts

Forecasts rely on manual inputs rather than real-time sales and partner data.

❌ Pricing disputes with customers

Steel prices fluctuate daily, but contract updates often lag behind.

❌ Missed delivery windows

Lack of synchronized production planning affects customer SLAs.

❌ Inaccurate financial reporting

Revenue leakage occurs due to errors in rebate calculation, discounts, and contract conditions.

Salesforce Manufacturing Cloud helps eliminate these inefficiencies by integrating the entire steel ecosystem.

4.How Salesforce Manufacturing Cloud Drives End-to-End Efficiency

Salesforce Manufacturing Cloud brings together every partner in the value chain — from field sales to OEM procurement — ensuring all parties share a single source of truth for sales, production, and pricing data.

Salesforce Manufacturing Cloud introduces a single, unified layer of visibility and collaboration across sales, operations, service, and finance.

Let’s break down the most powerful capabilities.

4.1 Unified Sales & Operations Visibility

Most steel companies maintain separate systems for:

- Sales orders

- Production planning

- Contract management

- Pricing

- Forecasts

This creates misalignment.

Manufacturing Cloud solves this by:

- Consolidating sales agreements

- Displaying committed vs. actual volumes

- Providing a real-time view of customer demand

- Enhancing internal collaboration among teams

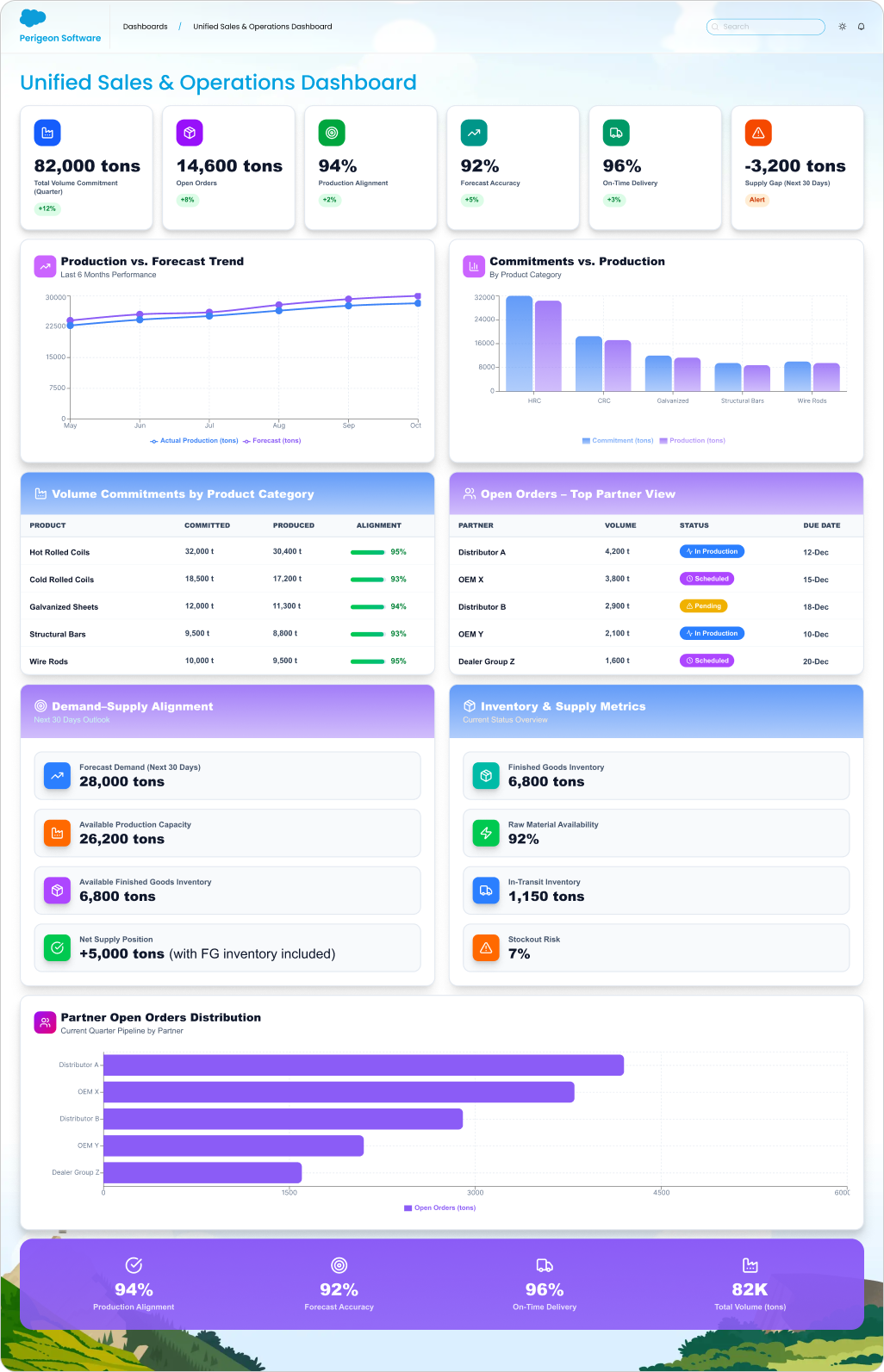

Managers can instantly see:

- Current contract utilization

- Customer order status

- Production capacity

- Enhancing internal collaboration among teams

Unified Sales & Operations Dashboard: Salesforce dashboard showing volume commitments, open orders, and production alignment.

4.2 Accurate Forecasting for Long-Lead Production

Steel production timelines demand accurate forecasting.

Manufacturing Cloud improves forecast accuracy through:

- AI-driven predictions based on historical customer orders

- Real-time collaboration with distributors, EPCs, and OEMs

- Automated alignment between sales, finance, and manufacturing

- Customer-level forecasting

- Product mix analysis

This ensures mills always know:

- What to produce

- When to produce

- How much to produce

Better forecasting = reduced idle time + optimized furnace loads + stabilized inventory.

4.3 Streamlined Contract & Pricing Management

The steel industry is heavily contract-driven with:

- Slab/coil pricing

- Spot rates

- Index-based pricing

- Price escalations

- Rebates and discounts

Salesforce Manufacturing Cloud helps streamline all contract workflows:

- Real-time contract amendments

- Automated pricing updates

- Customer-specific rebate visibility

- Version control and audit trail

- Volume tracking tied to contract terms

The result: fewer disputes and faster negotiations.

4.4 Real-Time Collaboration Across Business Units

Steel companies often operate across:

- Multiple plants

- Global offices

- Regional distributors

- EPC project customers

- Raw material suppliers

Collaboration delays can cost millions.

Salesforce connects every stakeholder through:

- Real-time updates

- Automated notifications

- Mobile dashboards

- Customer & distributor portals

- Order tracking tools

This creates a seamless collaboration layer across the supply chain.

4.5 Enhanced Production Planning with AI Insights

Manufacturing Cloud integrates with ERP systems to provide accurate production insights.

AI helps:

- Predict demand spikes

- Optimize furnace and rolling schedules

- Identify capacity bottlenecks

- Recommend ideal production sequences

- Improve material yield efficiency

With predictive insights, manufacturers achieve more output with less waste — a direct boost to profitability.

AI Forecast and Production Optimization: Chart showing predicted steel demand vs. actual production capacity.

5. Case Example: Efficiency Transformation in Steel Manufacturing

Manufacturer Profile:

A regional steel producer supplying construction and automotive-grade steel.

Challenges:

- Inaccurate forecasting

- Inefficient contract management

- Frequent pricing disputes

- Poor distributor visibility

- Inventory mismatches

Perigeon Software’s Salesforce Solution:

- Implemented Manufacturing Cloud

- Automated sales agreements

- Created forecasting dashboards

- Integrated ERP for live production data

- Built distributor visibility portals

- Enabled AI-driven demand models

Results Achieved:

Improvement AreaOutcomeForecast accuracy+42%Contract cycle time-37%Pricing disputesEliminatedInventory optimization+28% efficiencyOn-time delivery+33%Partner satisfaction+50%

Efficiency improved across the entire organization.

| Improvement Area | Outcome |

|---|---|

| Forecast accuracy | +42% |

| Contract cycle time | -37% |

| Pricing disputes | Eliminated |

| Inventory optimization | +28% efficiency |

| On-time delivery | +33% |

| Partner satisfaction | +50% |

6. Key Business Outcomes for Steel Manufacturers

✔ Higher forecast accuracy

✔ Reduced production delays

✔ Better alignment between sales & operations

✔ Lower operating costs

✔ Faster response to market volatility

✔ Stronger distributor & customer relationships

✔ Improved revenue and margin accuracy

✔ Enhanced decision-making with real-time insights

Salesforce Manufacturing Cloud becomes the digital backbone of modern steel plants.

7. Why Partner with Perigeon Software

Perigeon Software specializes in Salesforce solutions tailored for the steel & metals sector.

We bring expertise in:

- Sales & operations alignment

- Contract and pricing automation

- Distributor and OEM collaboration portals

- Forecasting and demand planning

- ERP integrations (SAP, Oracle, Infor, Microsoft)

- AI-driven analytics and reporting

Our approach ensures every steel manufacturer achieves measurable operational efficiency and business value.

8. Conclusion

Efficiency is not optional in the steel industry — it’s the foundation of survival and growth.

With Salesforce Manufacturing Cloud, steel manufacturers can modernize operations, improve forecasting, create transparency, and unlock significant competitive advantage.

Perigeon Software helps accelerate this digital transformation with deep manufacturing expertise and Salesforce mastery.