Table of content

Introduction

The Construction Equipment Manufacturing Landscape

Why Forecast Accuracy Matters in Heavy Equipment

Challenges in Forecasting Construction Equipment Demand

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

Case Study: Forecast Transformation in Construction Equipment OEM

The Future of Forecasting in Heavy Equipment

Conclusion

Introduction

The construction equipment sector is the backbone of global infrastructure development — producing excavators, bulldozers, loaders, cranes, and more. The global market is projected to surpass $200 billion by 2030 (Grand View Research, 2025).

Yet manufacturers face a forecasting crisis. Long lead times and cyclical demand make it extremely difficult to align production with actual market needs. According to McKinsey (2024), forecast deviation in construction equipment averages 25% annually, leading to inventory pileups or missed sales opportunities.

Salesforce Manufacturing Cloud addresses this problem by unifying dealer forecasts, integrating with ERP systems, and using AI-powered insights to deliver accurate, reliable demand predictions.

The Construction Equipment Manufacturing Landscape

- Segments: Earthmoving equipment, material handling, road construction machines, cranes.

- Sales Model: Predominantly through dealer/distributor networks.

- Customers: Governments, infrastructure contractors, real estate developers, mining companies.

- Revenue Mix: New machinery + service contracts, parts, and financing.

? Accurate forecasting is the foundation of profitable, predictable growth.

Why Forecast Accuracy Matters in Heavy Equipment

- Production Planning → Factories must align with real demand to avoid costly idle capacity.

- Dealer Trust → Meeting commitments builds confidence and loyalty.

- Financial Predictability → Accurate forecasts stabilize cash flow and shareholder expectations.

- Resilience → Better preparedness for economic swings in infrastructure spending.

Challenges in Forecasting Construction Equipment Demand

1. Cyclical Demand & Economic Sensitivity

- Demand tied to infrastructure budgets, real estate markets, and commodity cycles.

- Economic downturns create sharp demand drops.

2. Dealer-Driven Sales Models

- OEMs rely on independent dealers across regions.

- Forecasts are often outdated or inaccurate.

3. Long Production Lead Times

- Machines can take months to build.

- Forecast errors cascade into late deliveries or overstock.

4. Seasonal & Regional Variations

- Infrastructure projects vary across geographies and climates.

- Seasonal shifts make demand unpredictable.

5. Data Silos Between Sales, Dealers & Production

- Sales tracked in CRM, operations in ERP, dealer forecasts in spreadsheets.

- No single version of the truth.

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

1. Account-Based Forecasting for Dealer Precision

- Forecast demand at the dealer/account level.

- Improves accuracy by 20–30% compared to aggregate forecasts.

2. Real-Time Dealer Demand Visibility

- Dealers update forecasts dynamically in Salesforce portals.

- OEMs instantly see demand changes and adjust production.

3. ERP & Production Planning Integration

- Connects Salesforce with ERP/manufacturing systems.

- Ensures factory schedules align with live demand.

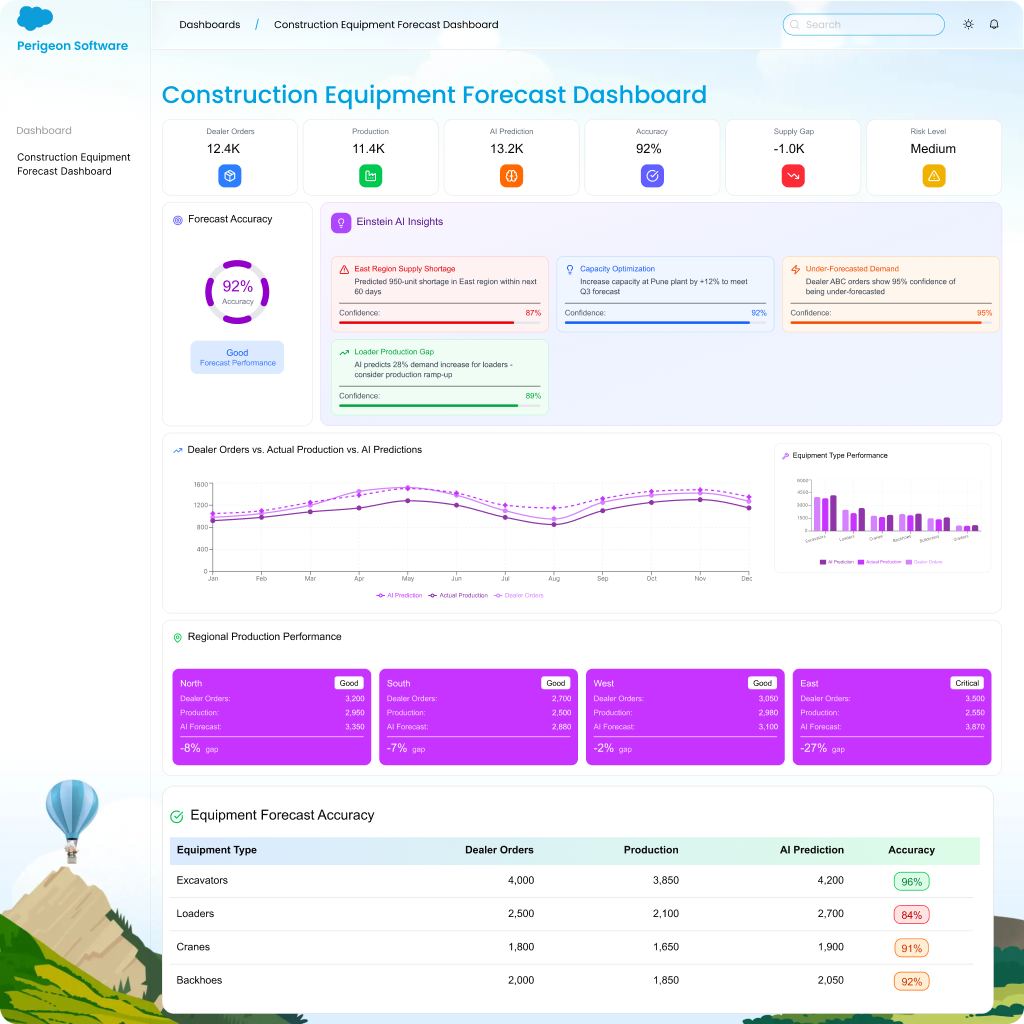

4. AI-Powered Demand Prediction

- Einstein AI integrates market, infrastructure, and commodity data.

- Predicts demand shifts before they impact production.

5. Dashboards for Executive Transparency

- Real-time dashboards display:

- Dealer performance

- Demand vs. actual production

- Forecast accuracy trendlines

Case Study: Forecast Transformation in Construction Equipment OEM

A global excavator OEM faced:

-

- Forecast deviation of 28% annually.

- Excess inventory worth $100M in warehouses.

After Salesforce:

- Forecast accuracy improved by 25%.

- Inventory costs reduced by 15%.

- On-time dealer delivery improved by 20%.

The Future of Forecasting in Heavy Equipment

- Digital Twins for Forecasting → Simulate machine demand vs. production capacity.

- Blockchain Dealer Commitments → Tamper-proof demand signals.

- AI Scenario Planning → Model budget changes, economic downturns, and commodity shocks.

- Sustainability Forecasting → Align production with ESG reporting.

Conclusion

Forecasting in construction equipment is complex — but solvable. Salesforce Manufacturing Cloud enables:

- Account-level, accurate forecasting

- Dealer-driven real-time visibility

- ERP–production alignment

- AI-powered predictive demand

- Transparent dashboards for leadership

For OEMs, Salesforce turns forecasting from a guess into a growth strategy.

?️ Ready to drive forecast accuracy in construction equipment?

? [Book a Manufacturing Cloud Strategy Session with Perigeon]