Table of content

Introduction

The Profitability Challenge in Chemical Manufacturing

Why Forecast Accuracy Is the Key to Competitive Advantage

Traditional Forecasting Challenges in the Chemical Industry

How Salesforce Manufacturing Cloud Transforms Forecasting Accuracy

Financial Benefits of Accurate Forecasting

Real-World Example: Boosting Margins with Data-Driven Forecasting

Role of Perigeon Software in Enabling Salesforce Success

Conclusion

? Introduction

In chemical manufacturing, profitability is a delicate balance between production efficiency, raw material costs, and market volatility.

Yet, one often-overlooked factor determines how well manufacturers can protect and grow margins: forecast accuracy.

When demand projections are wrong, the effects ripple through every department — from overstocked raw materials to unfulfilled customer orders and wasted production runs.

This is where Salesforce Manufacturing Cloud comes in — transforming data, collaboration, and forecasting into a unified system that drives predictable profitability.

“Forecast accuracy isn’t just about predicting demand — it’s about protecting margins and ensuring every production run counts.”

? The Profitability Challenge in Chemical Manufacturing

Chemical production is capital-intensive, energy-driven, and highly sensitive to fluctuations in both raw material prices and market demand.

Even minor forecast inaccuracies can lead to significant financial impacts.

Common profitability drain points include:

- Overstocking high-value raw materials that tie up working capital

- Underproduction during demand surges, leading to lost sales

- Overproduction leading to unsold inventory or product spoilage

- High logistics and warehousing costs

- Poor visibility into customer or distributor demand

In a McKinsey survey, chemical companies with accurate forecasts achieved 15–25% higher EBIT margins compared to peers with limited demand visibility.

That’s why improving forecasting accuracy isn’t a “data project” — it’s a profitability strategy.

? Why Forecast Accuracy Is the Key to Competitive Advantage

Accurate forecasting provides a strategic edge in:

- Production planning – Ensures optimal use of resources and plant capacity.

- Procurement efficiency – Prevents overbuying expensive raw materials.

- Supply chain agility – Minimizes delays and reduces operational bottlenecks.

- Customer satisfaction – Ensures timely delivery and reliable service levels.

In short, better forecasting equals better decision-making, leaner operations, and higher margins.

⚠️ Traditional Forecasting Challenges in the Chemical Industry

Despite the importance of forecasting, many chemical manufacturers still rely on outdated or siloed processes:

- Disconnected Systems – Sales, production, and finance data exist in separate systems, making consolidated forecasting difficult.

- Manual Data Consolidation – Spreadsheets and email-driven updates delay insights.

- Lack of Real-Time Market Data – Forecasts don’t reflect demand shifts or pricing fluctuations in time.

- Poor Collaboration – Limited visibility between sales teams, distributors, and production units.

- Reactive Adjustments – Manufacturers often react to missed targets rather than proactively plan based on predictive analytics.

The result? Lost profitability and strained supply chains.

⚙️ How Salesforce Manufacturing Cloud Transforms Forecasting Accuracy

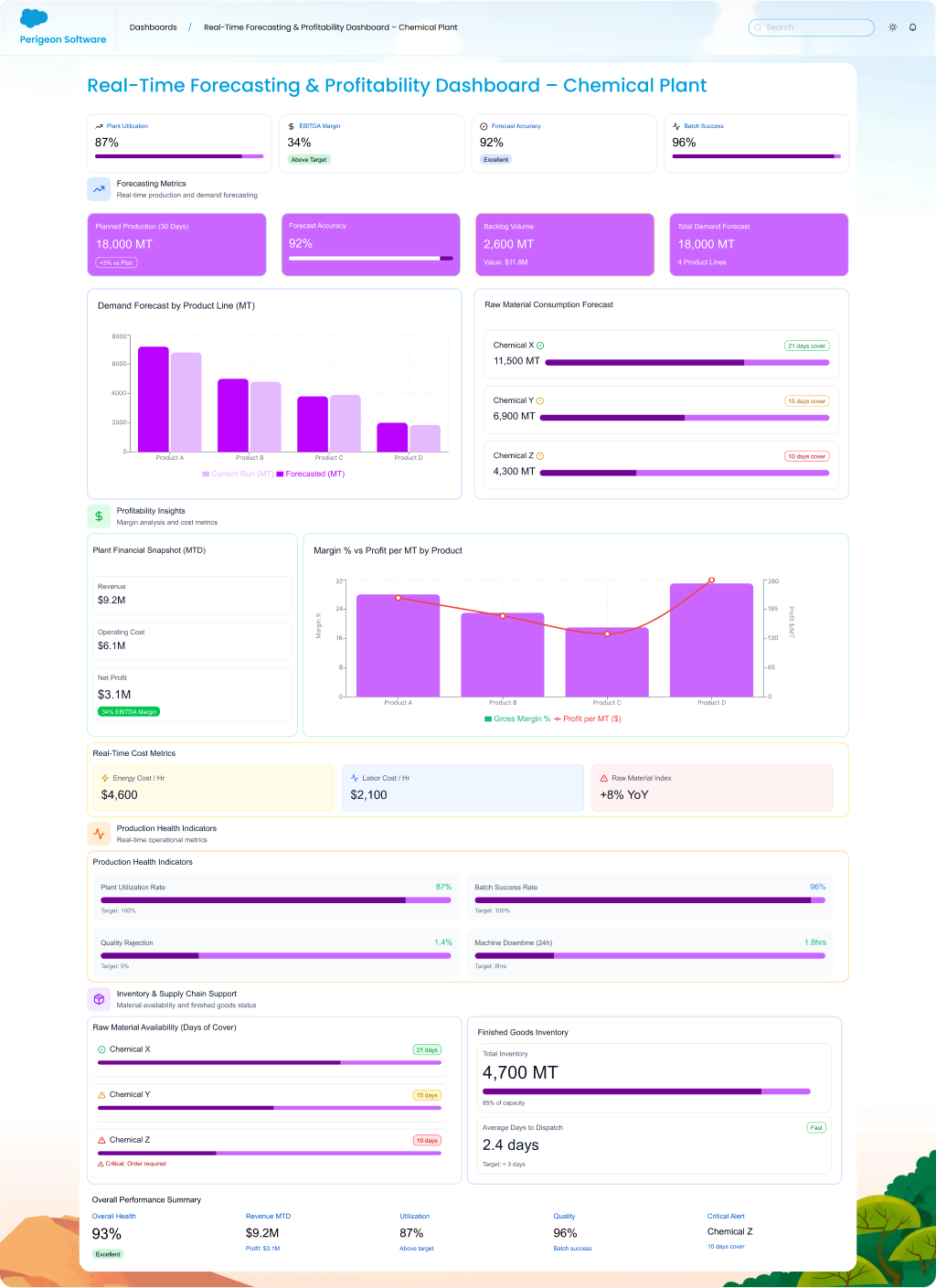

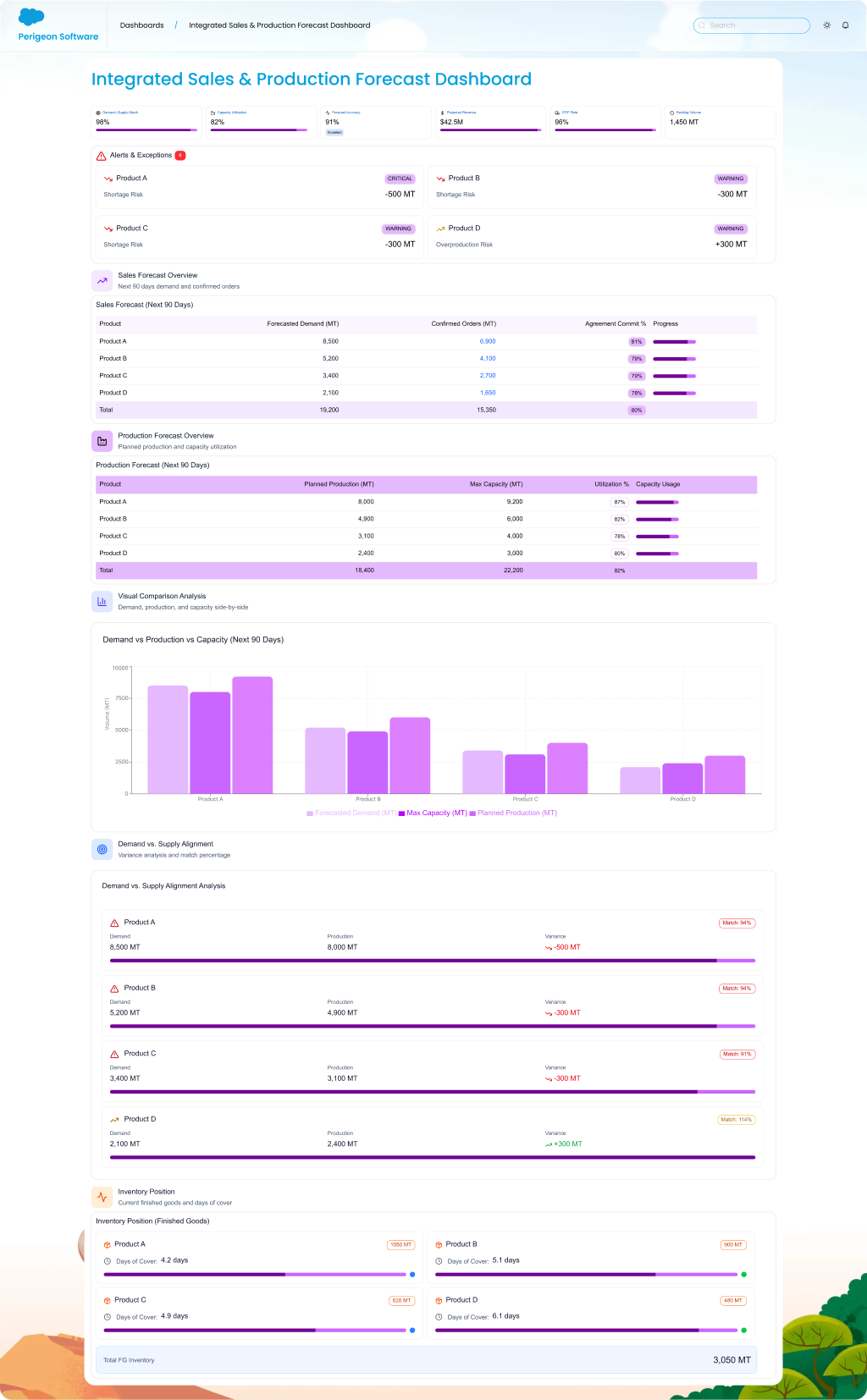

Salesforce Manufacturing Cloud provides a unified platform that bridges sales, operations, and finance — enabling chemical manufacturers to forecast accurately and act decisively.

1️⃣ Unified Sales & Operations Data

The platform integrates data from multiple systems — CRM, ERP, and production management — creating a single source of truth.

Manufacturers gain:

- Real-time insights into order volumes and customer commitments

- Accurate revenue projections

- Synchronization between sales agreements and production schedules

This integration reduces manual errors and provides full visibility into future demand.

2️⃣ Predictive Insights with Einstein Analytics

Salesforce’s Einstein Analytics applies AI and machine learning to analyze historical sales patterns, seasonal demand, and distributor data.

It identifies trends that humans often miss, such as:

- Demand variations by region or distributor

- Raw material consumption patterns

- Predictive pricing shifts based on market volatility

With AI-powered recommendations, manufacturers can plan production more accurately — optimizing both capacity utilization and cost efficiency.

3️⃣ Improved Collaboration Across the Value Chain

Accurate forecasting requires transparent collaboration between manufacturers, distributors, and suppliers.

Through Salesforce Experience Cloud, distributors and partners can:

- Input forecast data directly

- Access order histories

- Provide real-time feedback on demand shifts

This two-way visibility ensures that forecasts remain dynamic and responsive — improving both accuracy and alignment across the supply chain.

4️⃣ Enhanced Visibility for Sales Agreements & Commitments

Manufacturing Cloud’s Sales Agreements module links customer contracts directly with production and financial forecasting.

This enables:

- Clear understanding of revenue commitments

- Accurate forecasting based on contractual obligations

- Better tracking of customer-specific trends and rebates

In the chemical industry, where long-term contracts dominate, this capability is crucial for margin stability.

? Financial Benefits of Accurate Forecasting

When forecasting becomes more precise, profitability follows.

? Lower Inventory Costs

Accurate forecasts help maintain optimal inventory levels, reducing storage costs and minimizing the risk of product expiration or degradation.

? Reduced Waste & Idle Production

Better alignment between demand and production eliminates unnecessary batch runs, lowering energy and raw material wastage.

? Better Raw Material Procurement

With forward visibility into demand, procurement teams can negotiate better supplier contracts and plan bulk purchases strategically — securing lower prices.

? Optimized Working Capital

Lean inventory and efficient cash flow improve liquidity, allowing manufacturers to reinvest in innovation and capacity expansion.

? Increased Customer Retention

Reliable delivery schedules and product availability build customer trust — directly driving repeat business and higher lifetime value.

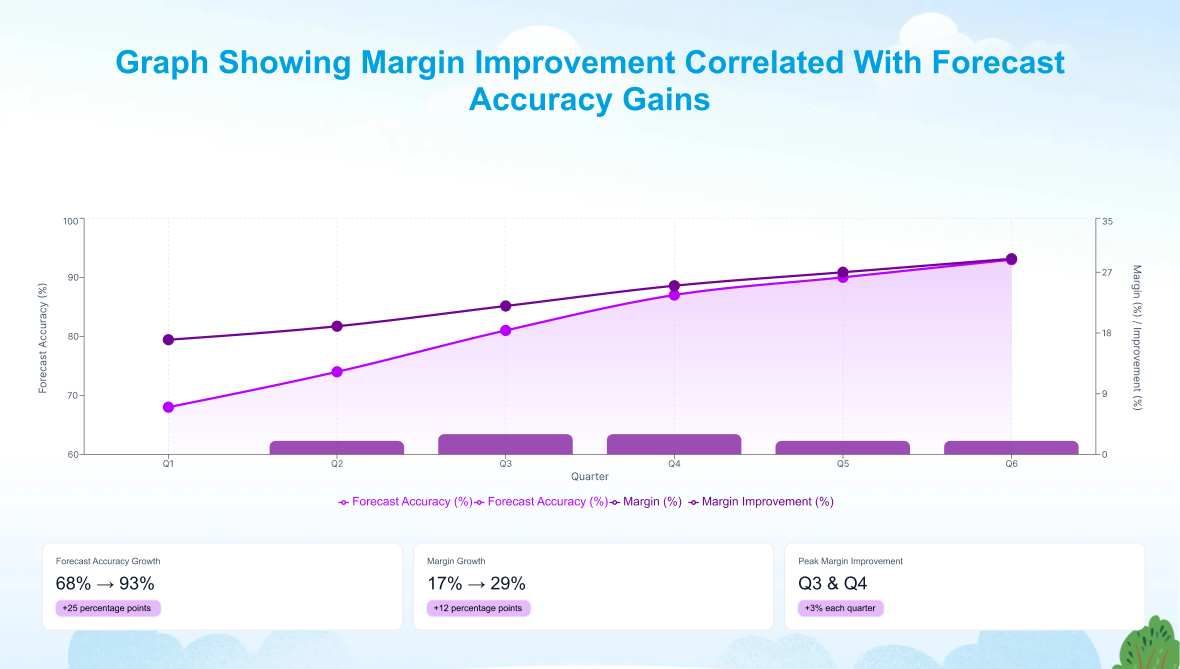

? Real-World Example: Boosting Margins with Data-Driven Forecasting

Scenario:

A specialty chemicals company producing industrial coatings struggled with volatile demand and raw material price spikes.

Challenges:

- Forecast variance exceeding 25%

- Overstocking costly base chemicals

- Delayed responses to distributor orders

Solution Implemented by Perigeon Software:

- Salesforce Manufacturing Cloud with Einstein Analytics

- Integration with ERP for live inventory and production data

- Real-time distributor forecasting via Experience Cloud

Results:

- Forecast accuracy improved by 35%

- Inventory costs reduced by 22%

- On-time order fulfillment improved by 18%

- Overall profitability increased by 16% within the first year

? Role of Perigeon Software

As a Salesforce Consulting Partner, Perigeon Software helps chemical and materials manufacturers unlock the full value of Salesforce Manufacturing Cloud.

Our capabilities include:

- End-to-end Salesforce Manufacturing Cloud implementation

- ERP and production system integration

- Forecasting model customization with Einstein Analytics

- Partner and distributor portal enablement

- Post-implementation support and managed services

We combine deep Salesforce expertise with real-world manufacturing understanding to deliver measurable business outcomes.

? Conclusion

Forecast accuracy isn’t a back-office function — it’s the foundation of profitability in chemical manufacturing.

With Salesforce Manufacturing Cloud, companies can unify data, improve collaboration, and leverage predictive insights to plan smarter and act faster.

When implemented by a trusted partner like Perigeon Software, forecasting becomes more than a number — it becomes a driver of sustained profitability, agility, and competitive advantage.