Table of content

Introduction

The Forecasting Challenge in Paper Manufacturing

The Cost of Inaccurate Forecasts

Why Traditional Forecasting Models Fall Short

How Salesforce Manufacturing Cloud Transforms Forecasting

Real-World Example: Forecast Precision in a Paper Mill

Benefits for Paper Manufacturers

Why Partner with Perigeon Software

Conclusion

? Introduction

For paper manufacturers, forecasting is more than just numbers — it’s the foundation for production planning, raw material procurement, and inventory management.

Yet, forecast inaccuracies remain one of the most persistent issues in the industry. Paper mills operate on tight margins and high production costs, so even small deviations in demand predictions can cause overproduction, wasted pulp, or missed customer deadlines.

Salesforce Manufacturing Cloud changes that equation by enabling manufacturers to use real-time data, AI insights, and unified forecasting tools — transforming how mills anticipate and meet demand.

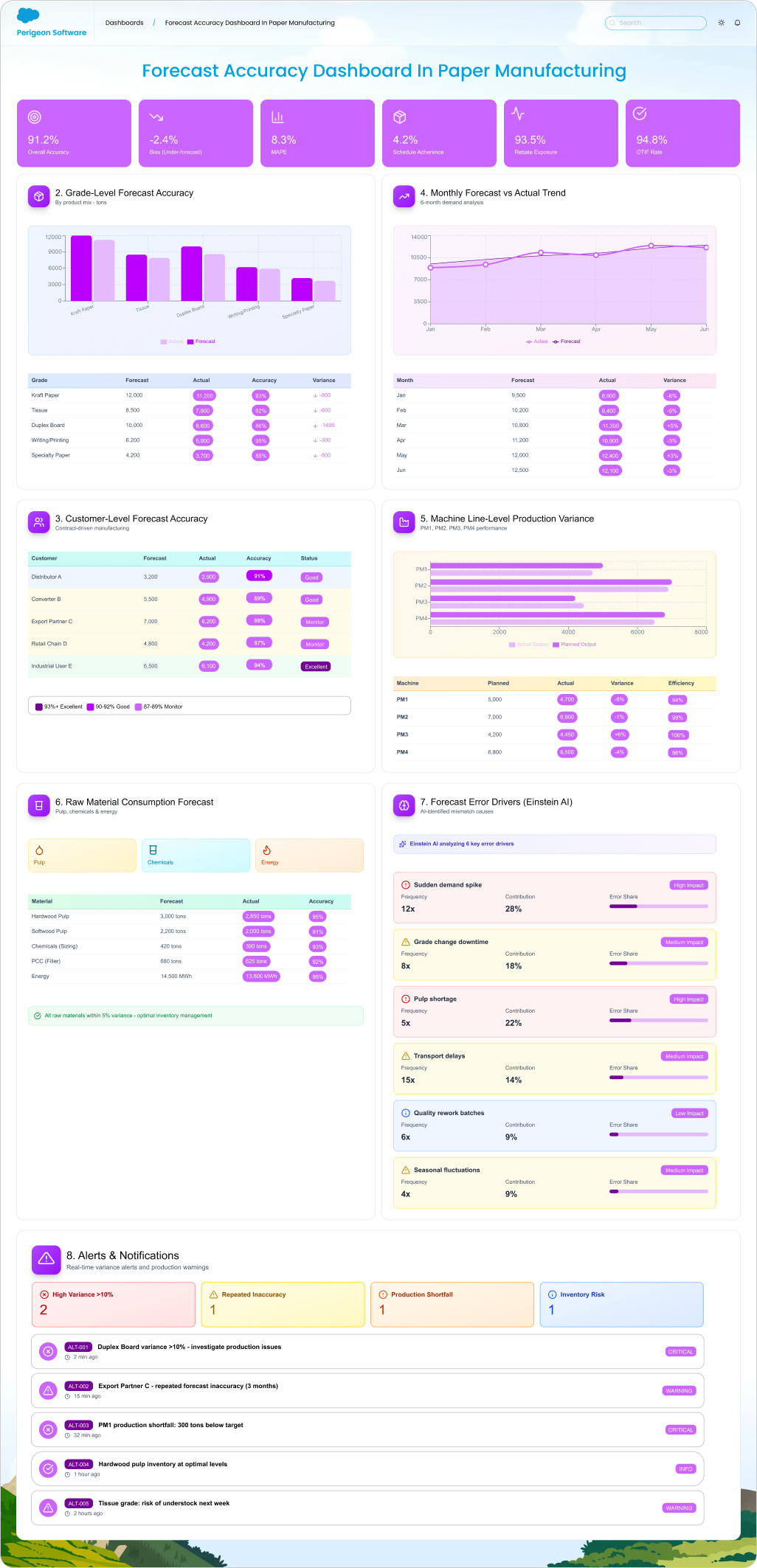

Forecast Accuracy Dashboard in Paper ManufacturingA Salesforce dashboard showing forecast vs. actual demand by paper grade, with trend lines and confidence intervals.

? The Forecasting Challenge in Paper Manufacturing

Forecasting demand for paper products isn’t simple — it involves managing:

- Seasonal fluctuations in printing and packaging demand.

- Long-term contracts with variable consumption rates.

- Rapid changes in sustainability and recycled paper trends.

- Unpredictable raw material and energy costs.

These factors often make traditional spreadsheet-based forecasting unreliable. Sales teams might predict growth in packaging grades, while operations see slower market movement — creating disconnects that ripple through the supply chain.

? The Cost of Inaccurate Forecasts

Inaccurate forecasts impact every aspect of a paper manufacturer’s business:

- ? Overproduction leads to excess inventory, higher storage costs, and wasted materials.

- ? Underproduction causes missed orders, delayed deliveries, and lost customer trust.

- ? Procurement inefficiencies result in suboptimal pulp or chemical purchasing.

- ? Production imbalance disrupts mill scheduling and increases energy costs.

Ultimately, forecast inaccuracy erodes both profitability and customer satisfaction — two pillars of competitive paper manufacturing.

⚙️ Why Traditional Forecasting Models Fall Short

Legacy ERP systems or Excel models can’t capture the complex data dynamics of modern manufacturing.

Challenges include:

- Static forecasts that don’t update in real time.

- Siloed data across sales, operations, and logistics.

- No link between sales agreements and production data.

- Limited ability to analyze historical demand patterns.

This is where Salesforce Manufacturing Cloud steps in.

? How Salesforce Manufacturing Cloud Transforms Forecasting

Salesforce Manufacturing Cloud provides a single source of truth for sales, production, and finance teams. Its forecasting capabilities go beyond static reports — combining AI analytics, live data, and predictive insights for truly accurate forecasts.

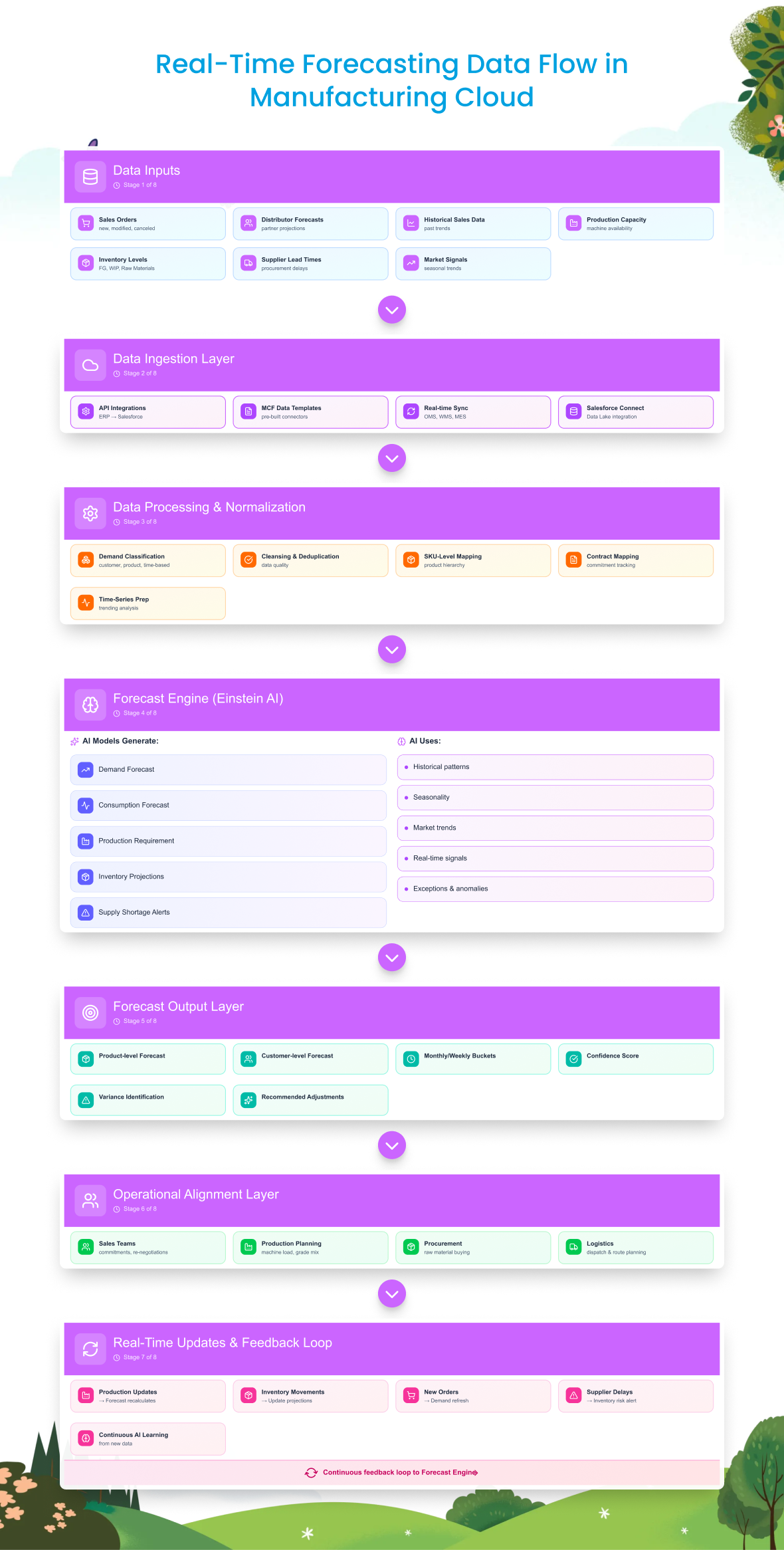

1️⃣ Real-Time Data Integration

Manufacturing Cloud connects to ERP, CRM, and production systems, giving teams real-time access to order trends, mill output, and customer consumption rates.

It helps production managers:

- Forecasts adjust dynamically based on order changes.

- Teams can track deviations between forecast and actuals instantly.

- Accurate data flows from customer demand to production planning.

Real-Time Forecasting Data Flow in Manufacturing CloudDiagram showing live data integration between sales, ERP, and production.

2️⃣ AI-Powered Predictive Forecasting

Salesforce Einstein Analytics leverages machine learning to analyze historical sales patterns, seasonality, and external factors like market demand and sustainability shifts.

Benefits:

- Detects demand spikes early.

- Suggests optimized production schedules.

- Reduces overstock and waste.

Example:

A mill producing recycled kraft paper can predict demand increases for eco-friendly packaging before the retail season peaks — improving preparedness and reducing last-minute procurement costs.

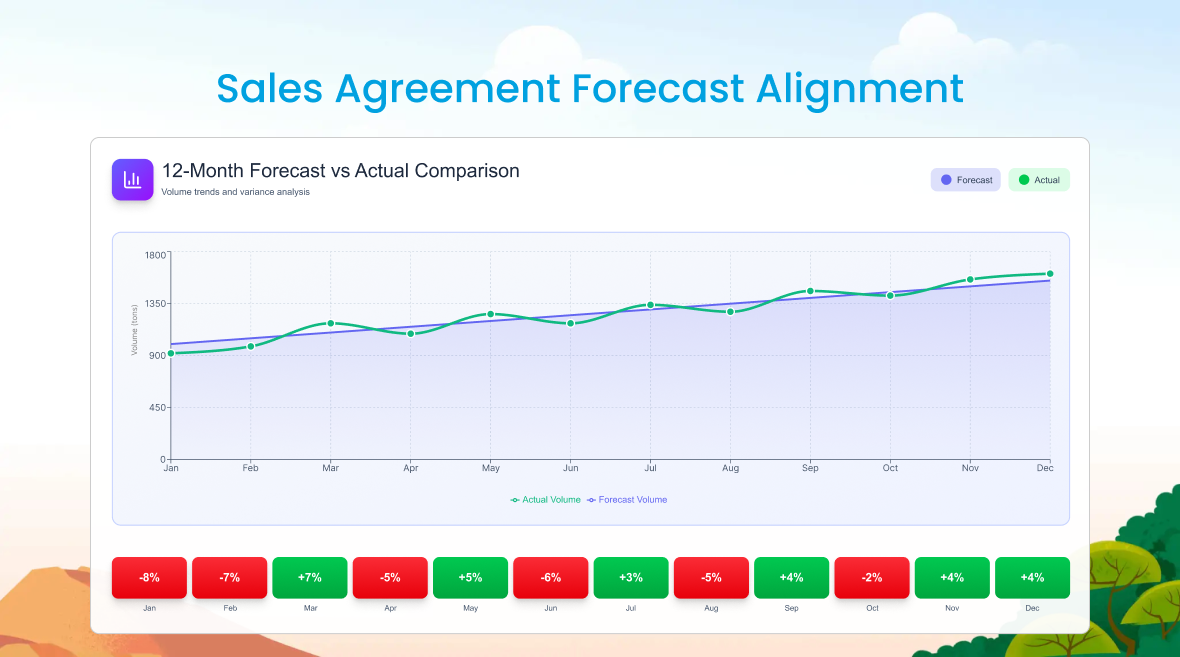

3️⃣ Sales Agreement Visibility

Manufacturing Cloud’s Sales Agreements feature centralizes all recurring contract data, including volumes, pricing, and performance commitments.

- Sales and production teams view the same live forecast.

- Deviations trigger automated alerts for review.

- Better synchronization of production capacity with sales commitments.

This ensures every forecast aligns with actual customer contracts, not just estimates.

Sales Agreement Forecast AlignmentVisual comparing forecast vs. actual order volumes under a long-term customer contract.

4️⃣ Collaboration Across Teams

With Manufacturing Cloud and Experience Cloud portals, communication becomes seamless across departments.

- Sales, operations, and procurement work from a unified dashboard.

- Forecast revisions are instantly visible to all stakeholders.

- Shared analytics promote accountability and agility.

No more miscommunication or version mismatches — just synchronized, data-driven planning.

? Real-World Example: Forecast Precision in a Paper Mill

Scenario:

A leading coated paper manufacturer relied on manual forecasting spreadsheets. Discrepancies between sales and operations led to frequent overproduction of low-demand SKUs.

Perigeon Software’s Solution:

- Implemented Salesforce Manufacturing Cloud.

- Connected ERP and CRM data streams for unified forecasting.

- Trained teams to use AI dashboards and sales agreements.

Results:

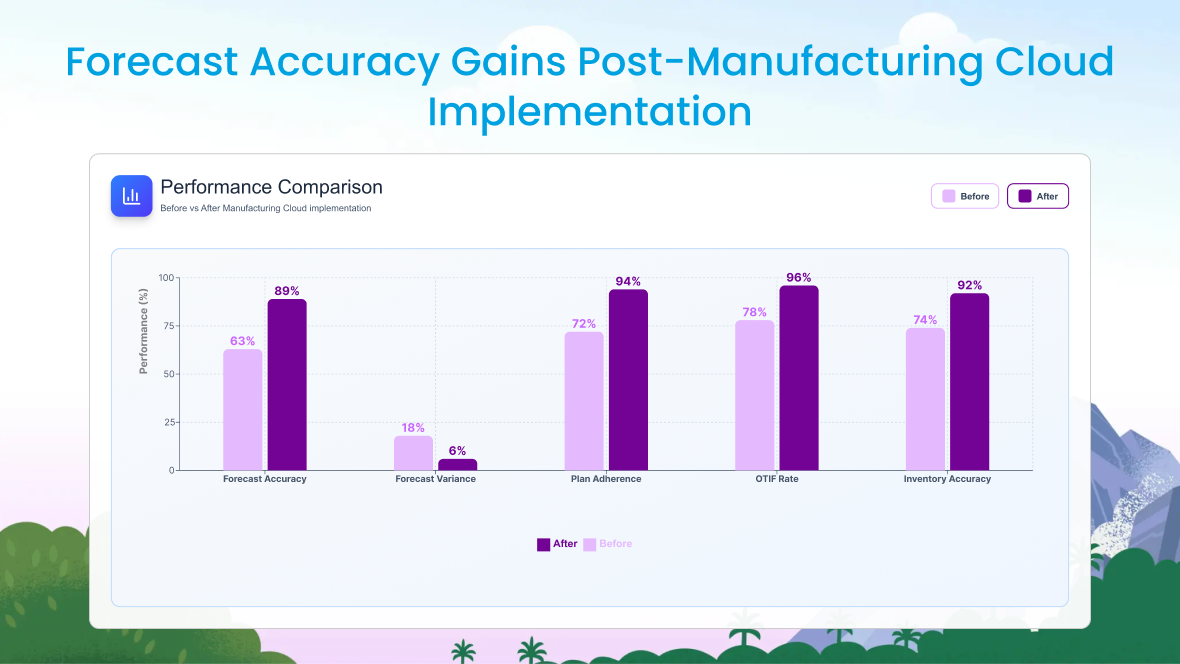

- Forecast accuracy improved by 40% within six months.

- Inventory carrying costs reduced by 22%.

- On-time order fulfillment increased by 18%.

? Benefits for Paper Manufacturers

Benefit AreaImpact Accuracy+40% improvementInventory Optimization-20% excess stockProduction Efficiency+25% better capacity planningProfit Margins+12% increaseCustomer Satisfaction+18% delivery improvement

Forecast Accuracy Gains Post-Manufacturing Cloud Implementation Bar chart comparing pre- and post-Salesforce implementation metrics.

? Why Partner with Perigeon Software

Perigeon Software specializes in helping paper manufacturers deploy and customize Salesforce Manufacturing Cloud for tangible results.

Our expertise includes:

- End-to-end Salesforce Manufacturing Cloud implementation.

- Integration with mill ERP systems and MES tools.

- Custom forecasting dashboards tailored to paper production cycles.

- AI-driven analytics for demand planning and inventory optimization.

We understand the unique challenges of paper mills — from variable pulp costs to multi-grade production lines — and we tailor Salesforce to fit your business processes precisely.

? Conclusion

Forecast accuracy is the difference between profitability and waste in the paper industry.

With Salesforce Manufacturing Cloud, manufacturers gain a unified, intelligent, and predictive system that ensures every forecast reflects real-world conditions.

By partnering with Perigeon Software, you can modernize forecasting, synchronize production, and deliver on your customer commitments with confidence.