Table of content

Introduction

The Complexity of Mining Equipment Supply Chains

Challenges in Managing Mining Supply Chains

How Salesforce Manufacturing Cloud Strengthens Supply Chains

Case Study: Global Mining OEM Supply Chain Transformation with Salesforce

The Future of Supply Chain Management in Mining Equipment

Conclusion

Introduction

Mining equipment manufacturers depend on highly complex, global supply chains — from engine and hydraulic system suppliers to steel manufacturers and electronics vendors. Each delay or disruption can stall multimillion-dollar mining projects.

According to PwC (2025), over 35% of mining OEMs reported supply chain delays costing them $50M+ annually due to fragmented planning and poor real-time coordination.

Salesforce Manufacturing Cloud provides a unified platform that strengthens mining equipment supply chains by integrating sales forecasts, supplier visibility, and AI-driven risk management — ensuring resilience and operational agility.

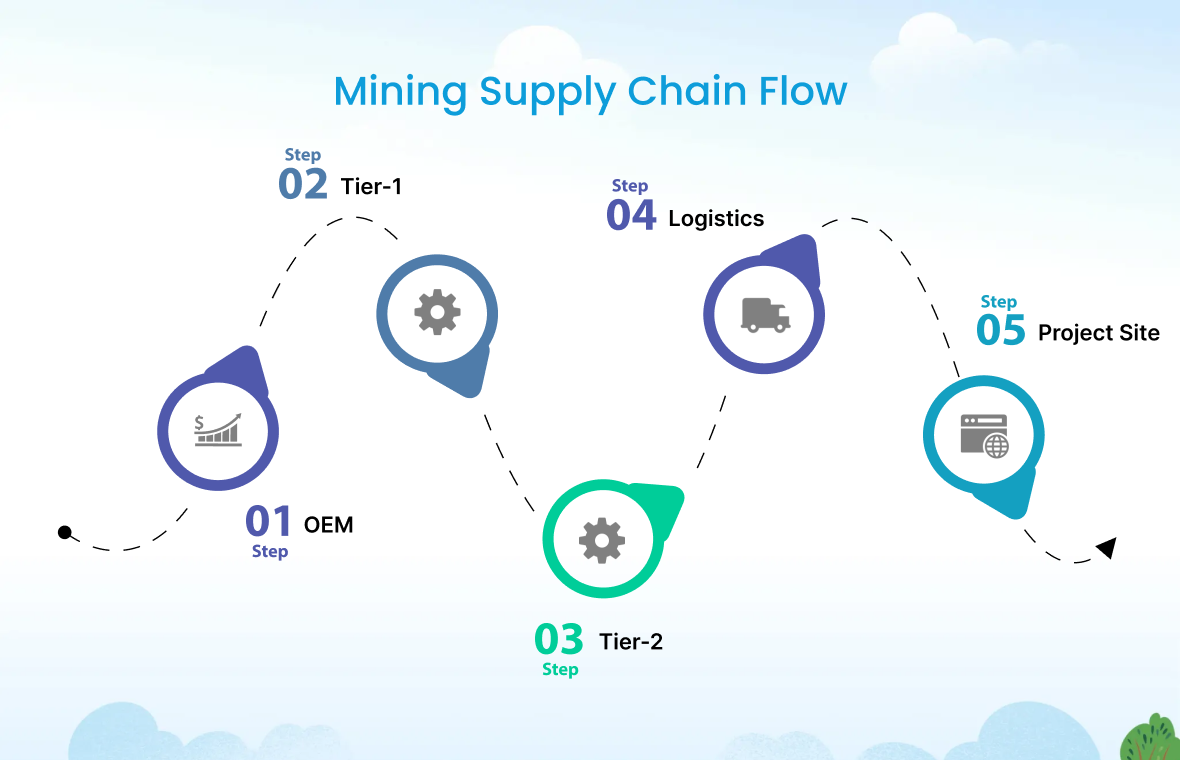

The Complexity of Mining Equipment Supply Chains

- Geographically distributed suppliers (steel, hydraulics, electronics).

- Long production cycles (12–24 months).

- Multi-stage approvals involving clients, governments, and contractors.

- Dependence on raw material availability (steel, copper, lithium).

? Without visibility, supply chain risks multiply — from component delays to compliance penalties.

Challenges in Managing Mining Supply Chains

1. Global Multi-Tier Supplier Networks

- Hundreds of suppliers across continents.

- Limited coordination beyond Tier-1 vendors.

2. Long Lead Times & Logistics Bottlenecks

- Heavy machinery components take months to produce and ship.

3. Commodity Market Volatility

- Fluctuating material costs affect supplier commitments.

4. Limited Transparency Across Suppliers

- No shared system for real-time performance tracking.

5. Compliance & ESG Traceability Gaps

- Governments require proof of ethical sourcing and carbon reporting.

How Salesforce Manufacturing Cloud Strengthens Supply Chains

1. Unified Sales & Supply Chain Visibility

- Links sales forecasts directly to material planning.

- Ensures suppliers align with confirmed project timelines.

2. Supplier Collaboration via Experience Cloud Portals

- Suppliers access:

- Production forecasts

- Delivery milestones

- Compliance requirements

- Promotes transparency and faster updates.

3. Real-Time Forecast Sharing & Material Planning

- Dealers and OEMs share updated demand signals.

- Suppliers automatically notified of requirement changes.

4. ERP & Logistics System Integration

- Syncs Salesforce with ERP (SAP, Oracle) and logistics systems.

- Enables end-to-end visibility — from raw materials to delivery.

5. AI-Powered Risk Prediction & Scenario Planning

- Einstein AI identifies:

- At-risk suppliers

- Potential delays or cost spikes

- Alternative sourcing scenarios

Case Study: Global Mining OEM Supply Chain Transformation with Salesforce

A mining OEM in Australia faced:

-

- Frequent supplier delays during commodity upswings.

- Lack of visibility into Tier-2 vendors.

After Salesforce:

- Supplier collaboration portals implemented across 4 continents.

- Delivery delays reduced by 32%.

- Real-time alerts prevented $12M in potential losses.

The Future of Supply Chain Management in Mining Equipment

- Blockchain-Enabled Traceability → Proof of ethical sourcing and ESG compliance.

- Digital Twin Supply Chains → Real-time simulation of logistics and material flow.

- AI-Driven Resilience Planning → Predictive mitigation of disruptions.

- Sustainable Supplier Scoring → Automated ESG risk assessment.

Conclusion

Mining supply chains demand agility, visibility, and trust. Salesforce Manufacturing Cloud provides:

- Unified view of sales and supply

- Supplier portals for collaboration

- ERP–logistics integration

- AI-powered risk forecasting

With Salesforce, mining OEMs build resilient, transparent supply chains that support global growth.

⛓️ Strengthen your mining supply chain today.

? [Book a Manufacturing Cloud Strategy Session with Perigeon]