Table of content

Introduction

The Complexity of Contracts in Auto Components Manufacturing

Key Challenges in Managing Complex Contracts

How Salesforce Manufacturing Cloud Simplifies Contract Management

Case Study: Streamlining Contract Management for a Tier-1 Supplier

The Future of Contract Management in Component Manufacturing

Conclusion

Introduction

In the auto components industry, contracts are the lifeblood of business relationships. From Tier-1 suppliers delivering engines and batteries to Tier-3 suppliers providing fasteners and plastics, every manufacturer operates under complex, long-term agreements with OEMs and distributors.

Yet, these contracts are rarely straightforward. They include:

- Volume-based commitments with penalties for non-fulfillment.

- Multi-tier rebate structures tied to sales performance.

- Global compliance clauses, varying by region.

Managing these contracts manually, or through disconnected systems, exposes manufacturers to risks such as penalties, disputes, and revenue leakage.

Salesforce Manufacturing Cloud provides a centralized, AI-driven platform for contract visibility, compliance tracking, and performance management, empowering component manufacturers to reduce risk and build stronger OEM relationships.

![]()

The Complexity of Contracts in Auto Components Manufacturing

Contracts in this sector are often:

- Multi-Year → Spanning 3–7 years, covering thousands of units annually.

- Multi-Tier → Involving OEMs, Tier-1, Tier-2, and Tier-3 suppliers.

- Conditional → Subject to rebates, penalties, or incentive triggers.

- Dynamic → Updated frequently to reflect EV adoption, new regulations, or product recalls.

? Without digital tools, contract management becomes error-prone, opaque, and costly.

Key Challenges in Managing Complex Contracts

1. Multi-Tier OEM & Supplier Agreements

- Contracts often cascade across OEMs, Tier-1s, and downstream suppliers.

- Lack of centralized visibility creates confusion and misalignment.

2. Volume-Based Rebates & Penalty Clauses

- Contracts include tiered rebates tied to production volumes or sales milestones.

- Penalty clauses apply if delivery or quality benchmarks aren’t met.

- Manual tracking leads to >s and lost trust.

3. Lack of Contract Transparency

- Dealers and OEMs rarely have real-time visibility into contract performance.

- This causes disputes, as parties interpret terms differently.

4. Manual Tracking & Compliance Risks

- Spreadsheets dominate tracking of rebates and penalties.

- Missed deadlines or errors lead to compliance breaches and fines.

5. Global Legal & Regulatory Variability

- Contracts span multiple jurisdictions (U.S., EU, Asia).

- Each region has unique legal frameworks for warranty, emissions, and safety compliance.

How Salesforce Manufacturing Cloud Simplifies Contract Management

Salesforce Manufacturing Cloud delivers a unified, transparent, and intelligent approach to contract management for component manufacturers.

1. Centralized Sales Agreements Repository

- Digitizes contracts and stores them in a single platform.

- Provides a 360° view of contract terms, commitments, and obligations.

- Accessible to both internal teams and external partners (as permissions allow).

? Example: A Tier-1 supplier can see its 3-year contract with an OEM, along with all milestones and performance metrics, in one dashboard.

2. Automated Rebate & Penalty Tracking

- Configures complex tiered rebate structures directly in Salesforce.

- Tracks rebate eligibility and penalties automatically, reducing disputes.

- Dealers and OEMs can view real-time status, eliminating reconciliation delays.

? Statistic: Gartner estimates that manual rebate tracking causes 3–5% revenue leakage annually in manufacturing.

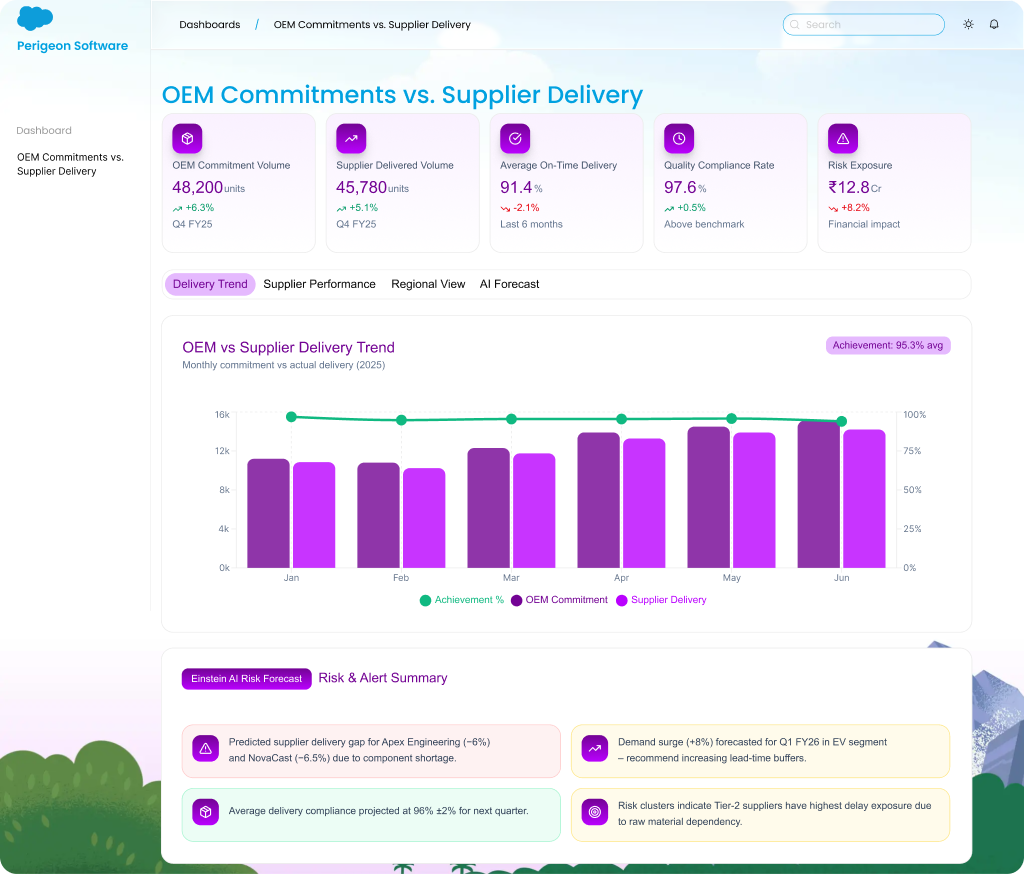

3. Real-Time Performance Monitoring

- Dashboards track:

- OEM commitments vs. actual deliveries

- Contractual milestones (e.g., EV component volumes)

- Rebate and penalty progress

- Ensures no contractual obligations are missed.

4. Dealer, OEM & Supplier Collaboration via Portals

- Salesforce Experience Cloud enables shared contract portals.

- Dealers, OEMs, and suppliers access up-to-date contract performance.

- Builds trust and transparency across the ecosystem.

5. Integration with ERP & Legal Systems

- Connects with ERP platforms (SAP, Oracle) for financial reconciliation.

- Integrates with legal contract management tools for compliance audits.

- Provides a closed-loop system between sales, operations, and legal.

6. AI-Powered Contract Analytics

- Einstein AI analyzes contract terms to:

- Flag at-risk commitments.

- Highlight opportunities for renegotiation.

- Identify patterns of disputes or penalties.

- Provides predictive insights into contract performance outcomes.

? Example: AI predicts that a supplier may miss a delivery milestone due to raw material shortages, prompting proactive OEM communication.

Case Study: Streamlining Contract Management for a Tier-1 Supplier

A European Tier-1 supplier managing 15+ OEM contracts faced:

-

- 30% of contracts requiring manual dispute resolution.

- Frequent penalties due to missed volume thresholds.

After implementing Salesforce Manufacturing Cloud:

- 90% of rebate calculations were automated.

- Penalty disputes reduced by 65% in the first year.

- OEM trust improved significantly, leading to a new 5-year strategic partnership.

The Future of Contract Management in Component Manufacturing

The next generation of contract management will be powered by:

- Smart Contracts (Blockchain): Automated execution of rebates and penalties.

- AI Contract Negotiation Assistants: Recommending optimal terms based on market trends.

- Sustainability Clauses: Embedding ESG metrics into contracts.

- Global Digital Standards: Harmonizing compliance across regions.

According to Accenture, automated contract lifecycle management could reduce operational costs by 30% in manufacturing by 2030.

Conclusion

Complex contracts are inevitable in the auto components industry, but manual management doesn’t have to be. Salesforce Manufacturing Cloud empowers suppliers to:

- Centralize and digitize contracts for full visibility.

- Automate rebate and penalty tracking to reduce disputes.

- Monitor performance in real time to avoid compliance risks.

- Enable transparency across OEMs, dealers, and suppliers.

- Leverage AI analytics for predictive contract performance.

For component manufacturers under OEM pressure to deliver more with less, Salesforce provides the foundation for contractual trust and efficiency.

? Ready to simplify your complex contracts?

? [Book a Manufacturing Cloud Strategy Session with Perigeon]