Table of content

Introduction

The Importance of Forecasting in Shipbuilding & Marine Manufacturing

Challenges in Forecasting Marine Manufacturing Demand

How Salesforce Manufacturing Cloud Improves Forecast Reliability

Case Study: Forecast Accuracy in Marine Manufacturing with Salesforce

The Future of Forecasting in Shipbuilding & Marine

Conclusion

Introduction

Forecasting in shipbuilding is one of the toughest challenges in manufacturing. Projects span years, demand fluctuates with global trade and defense budgets, and supply chain risks constantly evolve.

A Deloitte study (2024) reported that forecast deviation in shipbuilding exceeds 25%, leading to missed deadlines and cost overruns.

Salesforce Manufacturing Cloud improves forecast reliability by combining account-based forecasting, AI insights, and supplier collaboration, ensuring that shipbuilders can plan production and revenue with confidence.

The Importance of Forecasting in Shipbuilding & Marine Manufacturing

Reliable forecasts enable:

- Production Planning → Allocate yard resources efficiently.

- Financial Predictability → Stable revenue recognition.

- Supplier Coordination → Ensure timely component delivery.

- Risk Management → Adjust to global trade disruptions.

Challenges in Forecasting Marine Manufacturing Demand

1. Long Build Times & Project Uncertainty

- Vessels take years to build.

- Forecasts must adapt to changing conditions.

2. Geopolitical & Trade Fluctuations

- Defense budgets shift with politics.

- Commercial demand depends on global trade flows.

3. Supply Chain Volatility

- Steel, electronics, and engine shortages disrupt plans.

- Long lead times make forecasting harder.

4. Fragmented Forecasting Tools

- Spreadsheets dominate marine forecasting.

- No unified system for accuracy.

5. Multi-Segment Complexity (Commercial vs. Defense)

- Different forecasting models for cargo ships vs. naval vessels.

- Managing both adds complexity.

How Salesforce Manufacturing Cloud Improves Forecast Reliability

1. Account-Based Forecasting for Marine Clients

- Forecast demand at the contract/client level.

- Aligns production capacity with client commitments.

2. AI-Powered Predictive Demand Models

- Einstein AI integrates market, trade, and budget data.

- Improves forecast accuracy by 20–30%.

3. ERP & Yard Production Integration

- Connects Salesforce with ERP and yard management.

- Provides a unified view of forecasts vs. production schedules.

4. Supplier & Partner Forecast Collaboration

- Suppliers access forecasts via portals.

- Enables joint planning to reduce delays.

5. Scenario Planning & Risk Modeling

- Simulates disruptions: steel shortages, trade shifts, budget cuts.

- Provides proactive alternatives.

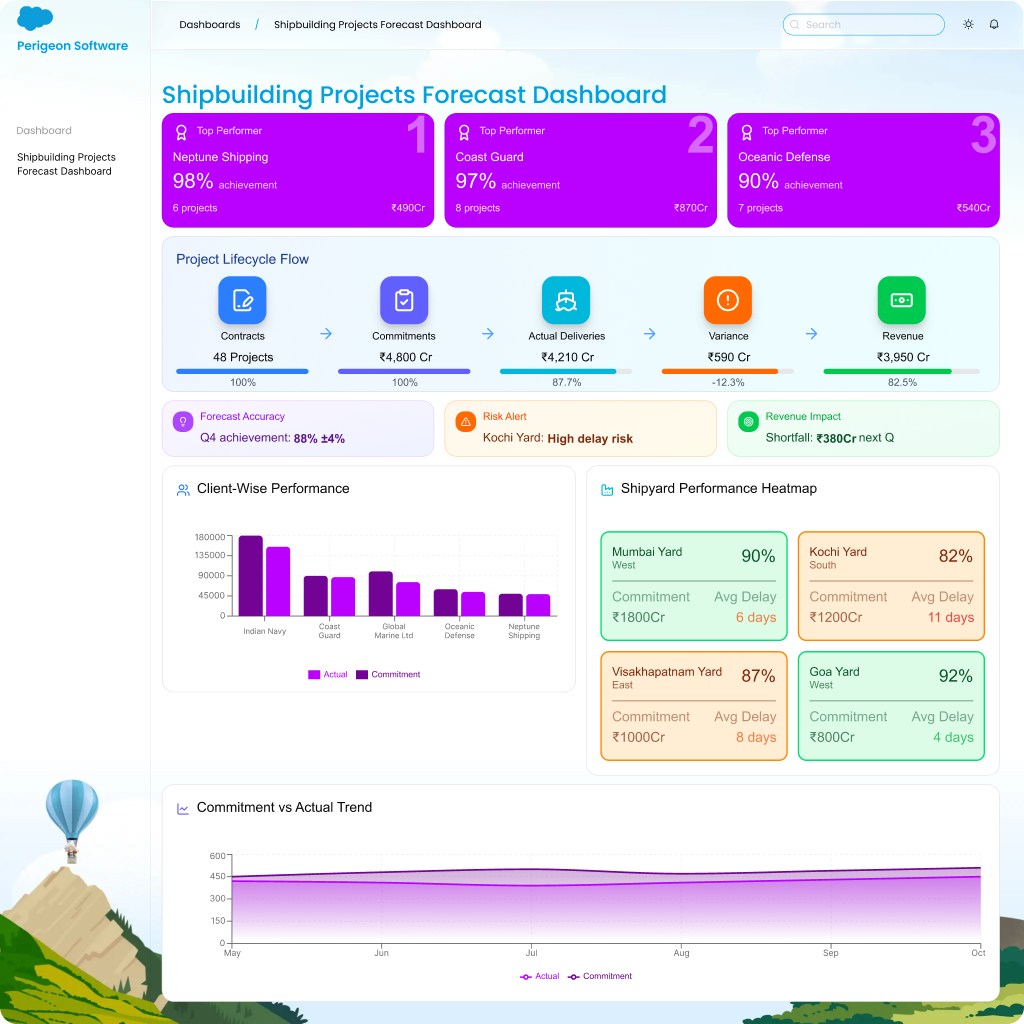

Case Study: Forecast Accuracy in Marine Manufacturing with Salesforce

A global shipbuilder producing both naval and commercial vessels faced:

-

- Forecast deviation of 27% annually.

- Cost overruns from supplier misalignment.

After Salesforce:

- Forecast accuracy improved to 93%.

- On-time delivery increased by 20%.

- Supplier disputes dropped significantly.

The Future of Forecasting in Shipbuilding & Marine

- Digital Twins → Simulate shipbuilding projects in real time.

- Blockchain Forecasting → Tamper-proof demand signals.

- AI-Driven Risk Alerts → Predict global trade shocks.

- Sustainability Forecasts → Carbon tracking in forecasts.

Conclusion

Forecast reliability is the foundation of profitable shipbuilding. Salesforce Manufacturing Cloud enables marine manufacturers to:

- Forecast at the account/contract level

- Leverage AI for demand accuracy

- Integrate ERP & yard systems

- Collaborate with suppliers transparently

- Plan scenarios proactively

With Salesforce, shipbuilders can turn uncertainty into predictability and trust.

? Ready to improve forecast reliability in shipbuilding?

? [Book a Manufacturing Cloud Strategy Session with Perigeon]