Table of content

Introduction

The Financial Complexity of Rubber Sales Agreements

Key Challenges in Traditional Agreement Management

Why Salesforce Manufacturing Cloud Is a Game Changer

Real-World Example: Revenue Accuracy in Action

Key Benefits for Rubber Manufacturers

Why Partner with Perigeon Software

Conclusion

? Introduction

In the rubber manufacturing industry, where price volatility, long-term contracts, and diverse customer demands are the norm, managing sales agreements is both critical and complex.

Manufacturers often deal with OEMs, distributors, and industrial buyers under multi-tiered contracts that specify quantities, pricing tiers, rebates, and performance obligations.

When managed manually, these agreements become a source of financial leakage, inconsistent forecasting, and missed revenue recognition opportunities.

Salesforce Manufacturing Cloud changes this by providing a centralized platform for tracking agreement performance, linking financials directly to sales data, and delivering real-time insights into revenue accuracy and profitability.

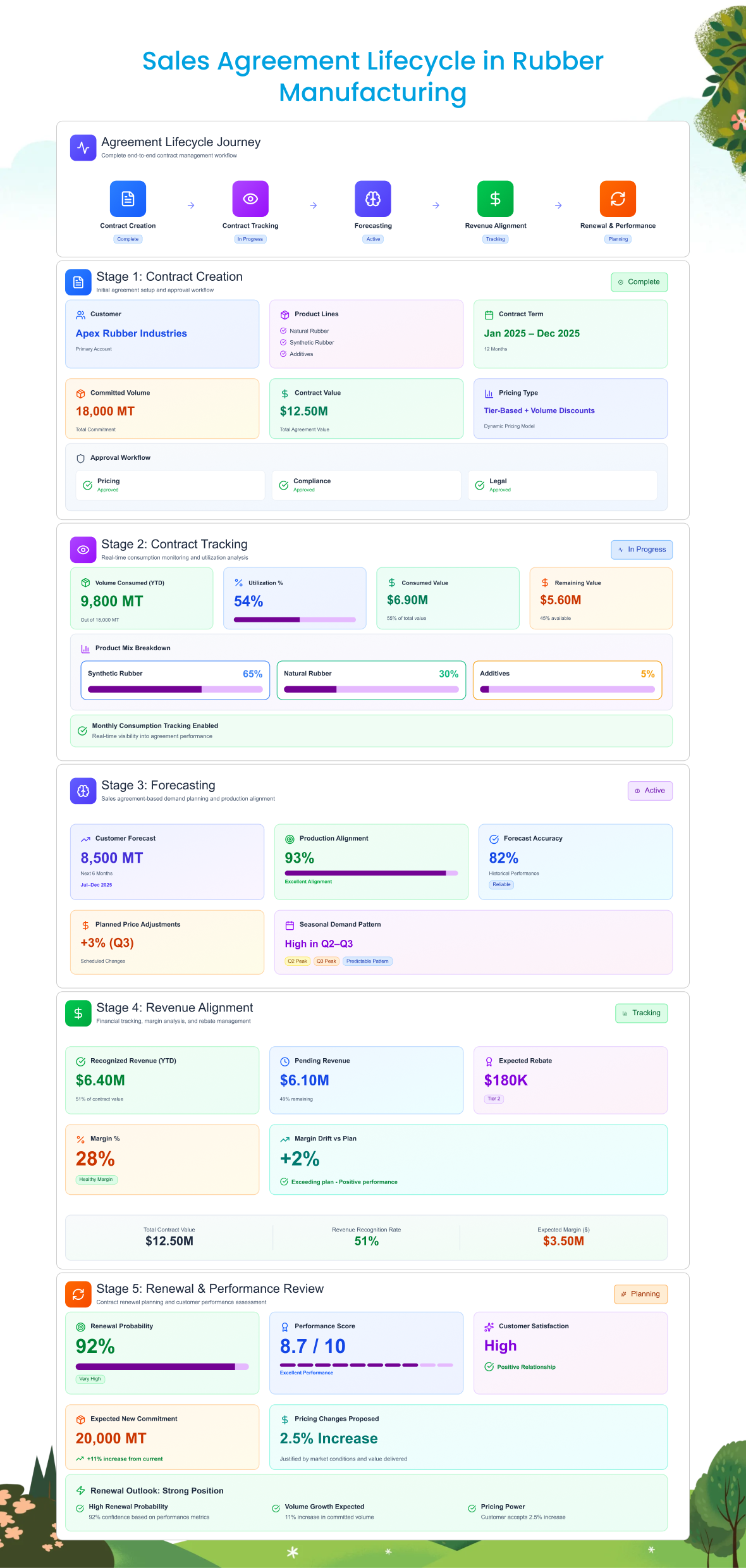

Sales Agreement Lifecycle in Rubber Manufacturing

Visual showing contract creation, tracking, forecasting, and revenue alignment within Salesforce Manufacturing Cloud.

? The Financial Complexity of Rubber Sales Agreements

Rubber manufacturers often operate under contract manufacturing models, supplying components or materials to OEMs and distributors based on pre-agreed pricing and volume commitments.

These agreements involve:

- Variable pricing based on raw material indices (like natural rubber or oil-based synthetics).

- Tiered rebates linked to purchase volume.

- Currency adjustments in global contracts.

- Frequent re-negotiations tied to market fluctuations.

Without real-time visibility into these financial variables, even profitable companies risk losing margins due to manual oversight and revenue misalignment.

⚠️ Key Challenges in Traditional Agreement Management

Even large rubber product manufacturers often rely on disconnected spreadsheets or legacy ERP systems that fail to capture dynamic agreement terms.

Common pain points include:

- ❌ Manual data entry errors leading to billing inconsistencies.

- ⏳ Delayed rebate calculations that distort financial forecasts.

- ? No automated link between actual sales and agreement performance.

- ? Limited transparency across finance, sales, and operations teams.

The result: lost rebates, delayed payments, inaccurate revenue projections, and strained customer relationships.

⚙️ Why Salesforce Manufacturing Cloud Is a Game Changer

Salesforce Manufacturing Cloud introduces a single digital source of truth that unifies contract terms, actual sales performance, and financial tracking — in real time.

Let’s explore how it strengthens financial transparency and revenue accuracy in rubber manufacturing.

1️⃣ Unified Sales Agreement Framework

Salesforce’s Sales Agreement feature lets manufacturers digitally manage long-term contracts that specify:

- Target volumes

- Price tiers

- Rebate programs

- Billing schedules

Each agreement automatically syncs with live orders, invoices, and revenue recognition data — eliminating manual effort.

Example:

A rubber hose manufacturer can track its contract commitments with automotive OEMs, ensuring billing aligns perfectly with agreed pricing tiers as volume thresholds are met.

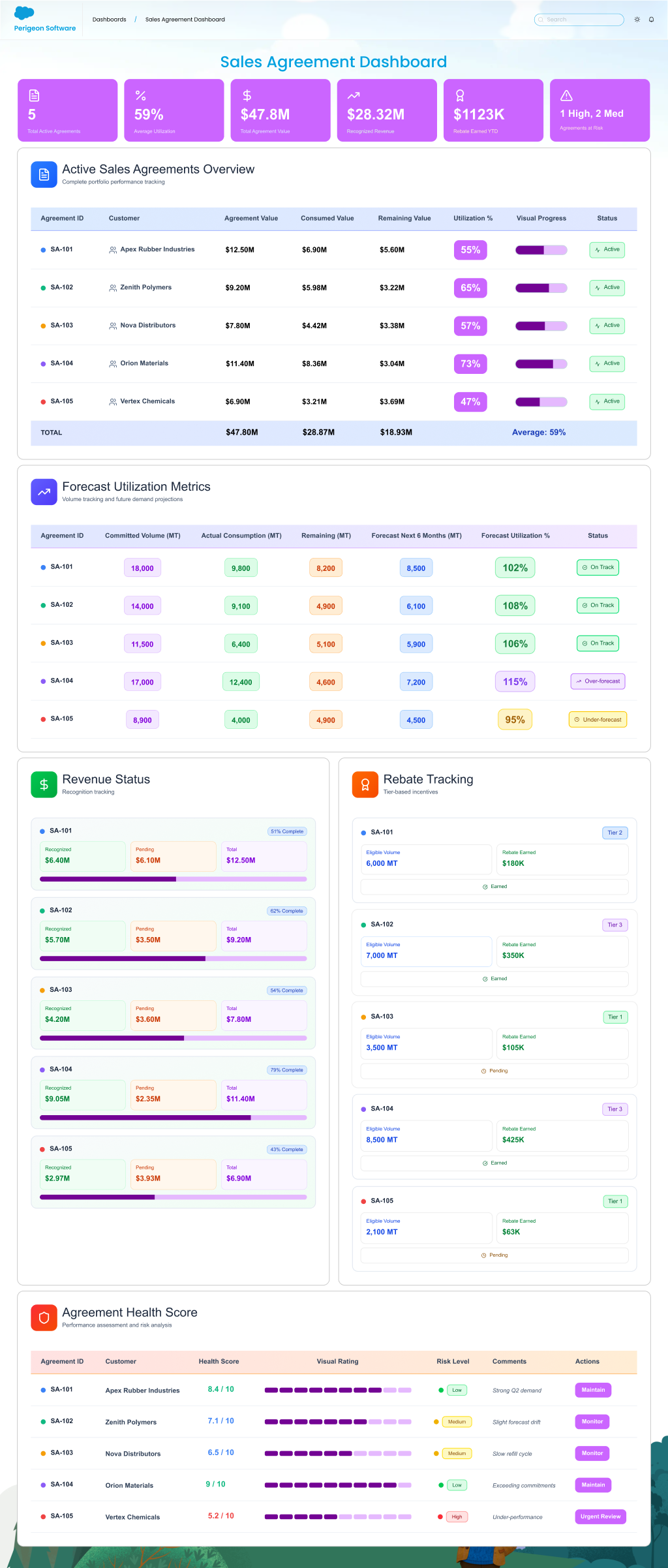

Sales Agreement Dashboard:Salesforce dashboard displaying active agreements, forecast utilization, and revenue status.

2️⃣ Real-Time Volume & Revenue Tracking

Manufacturing Cloud enables finance and sales teams to view real-time agreement utilization — showing how much revenue has been realized against contractual commitments.

Benefits include:

- Instant insight into unfulfilled agreements.

- Automated variance alerts for underperformance.

- Accurate accruals for financial closing.

This eliminates revenue leakage and ensures accurate financial forecasting across global markets.

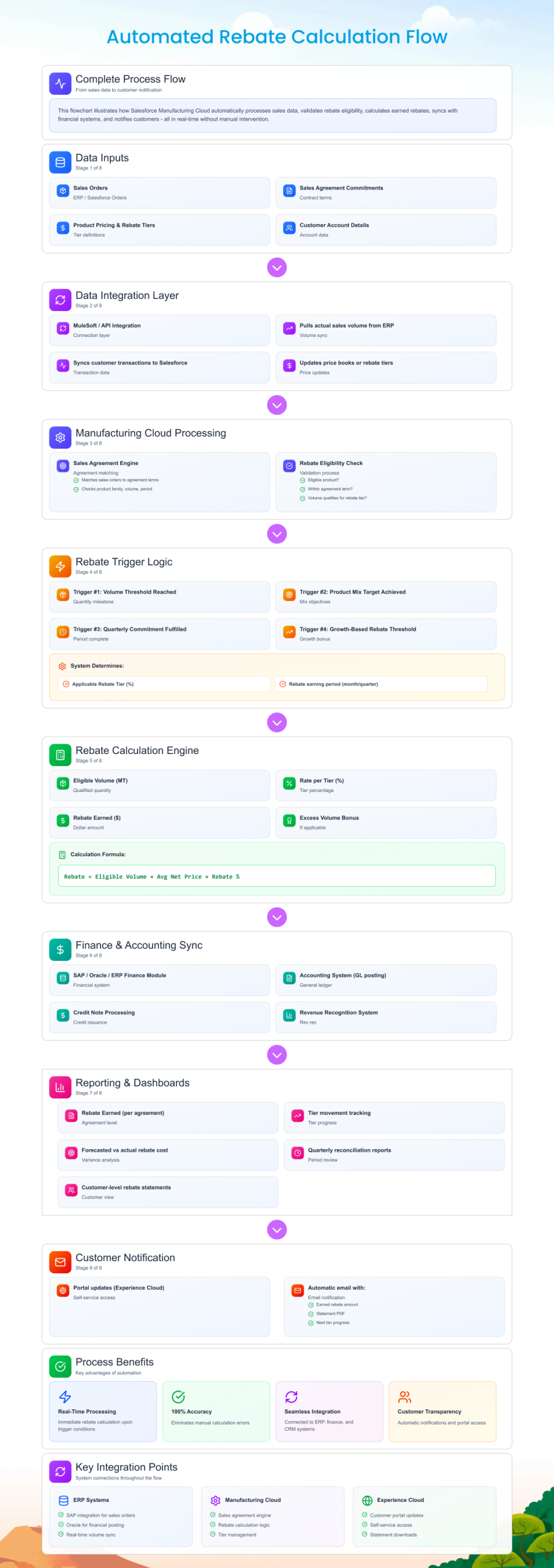

3️⃣ Automated Rebate and Price Adjustment Management

Rebates are central to the rubber industry’s financial operations — rewarding customers who meet volume targets or specific product commitments.

Salesforce Manufacturing Cloud automates rebate tracking by:

- Linking rebate tiers directly to contract and sales data.

- Applying price adjustments automatically as thresholds are reached.

- Integrating with ERP to update invoices and ledger entries in real time.

This ensures every rebate is accurate, auditable, and transparent, significantly reducing administrative overhead.

Automated Rebate Calculation FlowDiagram showing how Manufacturing Cloud links sales data to rebate triggers and accounting systems.

4️⃣ Integration with ERP for Financial Accuracy

Manufacturing Cloud easily integrates with SAP, Oracle, or other ERP systems — syncing pricing, inventory, and financial data for full accuracy.

This integration enables:

- Automated reconciliation of sales vs. invoicing data.

- Transparent revenue recognition and audit trails.

- Unified dashboards for finance, sales, and operations teams.

Together, these capabilities ensure that financial outcomes match operational realities, driving accountability across departments.

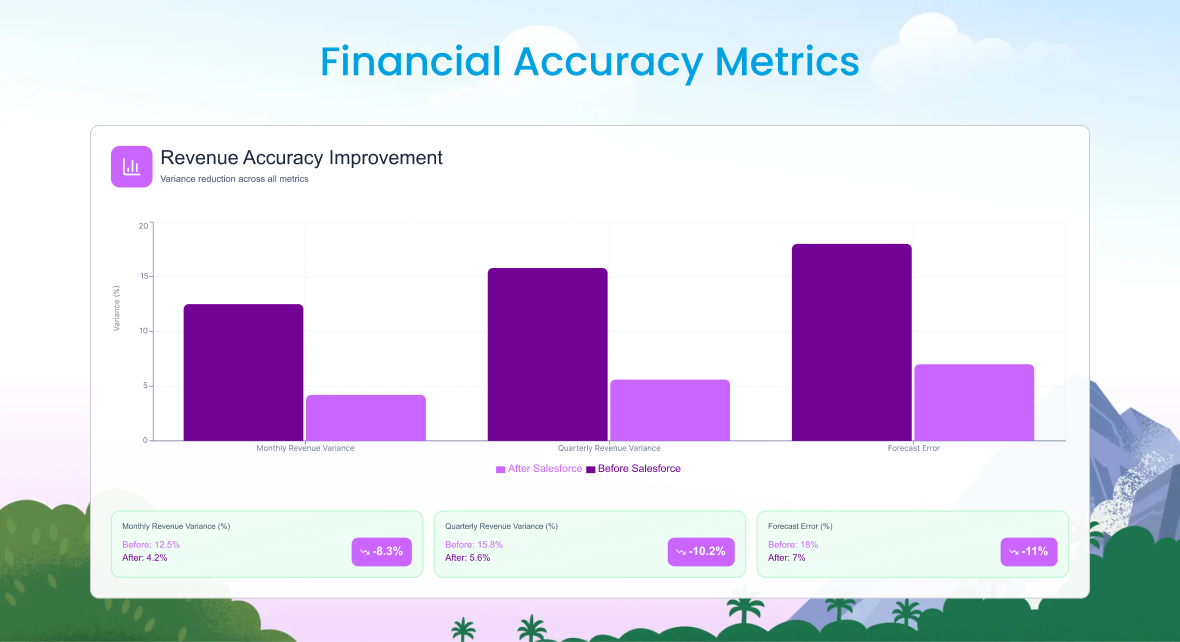

? Real-World Example: Revenue Accuracy in Action

Scenario:

A global industrial rubber products manufacturer supplied OEMs under volume-based contracts with quarterly rebates. Manual data entry and offline tracking caused discrepancies between sales reports and revenue statements.

Perigeon Software’s Solution:

- Implemented Salesforce Manufacturing Cloud with custom agreement templates.

- Integrated the platform with SAP ERP for real-time pricing updates.

- Configured automated rebate logic tied to sales performance.

Results:

- Rebate processing time reduced by 70%.

- Revenue variance between sales and finance reduced from 6% to <1%.

- Quarterly financial close accelerated by 30%.

? Key Benefits for Rubber Manufacturers

Benefit AreaImpactRevenue Accuracy+99% precision in sales agreement trackingRebate Efficiency-70% admin effortForecast Reliability+35% improvementFinancial TransparencyEnd-to-end audit trail visibilityCustomer TrustImproved satisfaction through consistent billing

Financial Accuracy Metrics: Chart showing pre- vs. post-Salesforce implementation improvements in revenue variance and rebate time.

? Key Benefits for Rubber Manufacturers

| Benefit Area | Impact |

|---|---|

| Revenue Accuracy | +99% precision in sales agreement tracking |

| Rebate Efficiency | -70% admin effort |

| Forecast Reliability | +35% improvement |

| Financial Transparency | End-to-end audit trail visibility |

| Customer Trust | Improved satisfaction through consistent billing |

? Why Partner with Perigeon Software

At Perigeon Software, we help manufacturers harness the full power of Salesforce Manufacturing Cloud to optimize sales agreement management.

Our consulting approach focuses on:

- Custom Sales Agreement Frameworks for rubber product pricing structures.

- ERP Integrations ensuring financial alignment across systems.

- Automated Rebate Modules tailored for high-volume B2B customers.

- Training & Change Management for sales and finance teams.

We combine deep manufacturing domain expertise with Salesforce implementation excellence — ensuring measurable ROI within months.

? Conclusion

In the competitive world of rubber manufacturing, financial transparency is non-negotiable.

By digitizing and automating sales agreement management with Salesforce Manufacturing Cloud, manufacturers can achieve:

- Accurate revenue recognition.

- Streamlined rebate tracking.

- Transparent, trust-based customer relationships.

Perigeon Software helps you turn complex financial workflows into a strategic advantage — ensuring that every contract contributes directly to your bottom line.