Table of content

Introduction

Challenges in Metal Fabrication Demand Forecasting

How Salesforce Manufacturing Cloud Improves Forecast Accuracy

Key Features Metal Fabricators Benefit From

Business Outcomes & Impact

Why Metal Fabricators Need Salesforce Today

Conclusion

Want to implement Salesforce Manufacturing Cloud for metal fabrication?

1.Introduction

Metal fabrication companies operate in a highly project-driven environment where demand fluctuates based on construction, automotive, machinery, and industrial orders.

Because customer timelines are unpredictable and pricing varies with raw material costs, forecasting demand is often inaccurate, delayed, and disconnected between sales and production teams.

Salesforce Manufacturing Cloud provides the unified forecasting engine metal fabricators need to plan confidently, reduce cost overruns, and eliminate production delays.

2. Challenges in Metal Fabrication Demand Forecasting

Metal fabricators struggle with:

❗ Highly variable order volumes

Customer demand often changes based on project timelines, leaving manufacturers unsure of future volumes.

❗ Material price fluctuations

Steel, aluminum, and alloys shift daily—impacting the accuracy of demand planning.

❗ Limited visibility into customer commitments

Many companies rely on spreadsheets, emails, and manual follow-ups.

❗ Misalignment between sales and production

Sales promises volumes that production cannot fulfill due to capacity limits.

❗ Distributor and OEM uncertainty

Forecasts depend heavily on partner data, which is often inconsistent.

These challenges create:

- Overstock and understock

- Production inefficiencies

- Delayed shipments

- Lost revenue from missed orders

3. How Salesforce Manufacturing Cloud Improves Forecast Accuracy

Salesforce Manufacturing Cloud provides components specifically designed for metal fabrication forecasting:

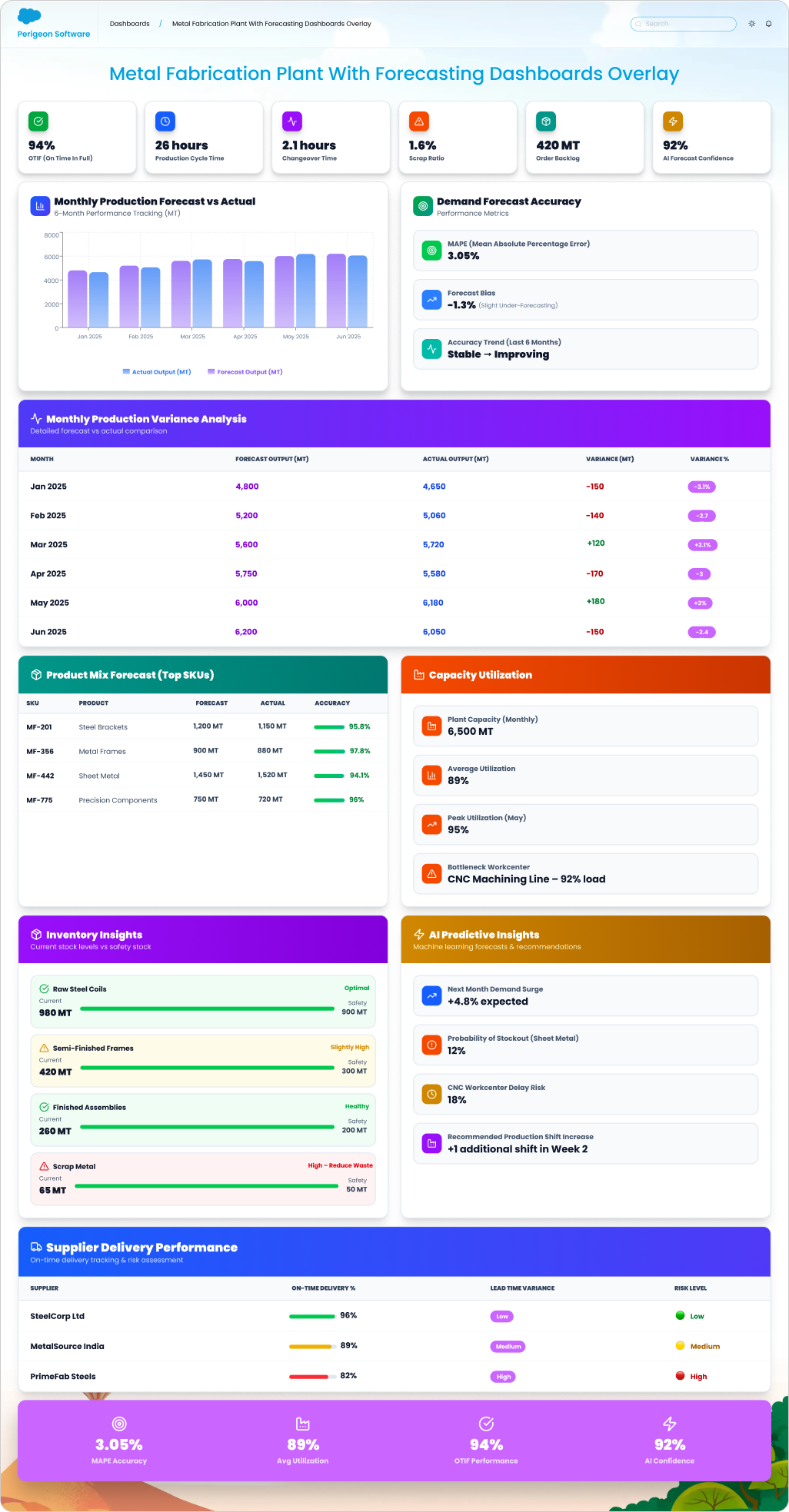

? Unified Sales & Operations Forecasting

Combines sales pipeline, historical order data, and current commitments into one complete forecast.

? Contract-Based Forecasting

Metal fabricators often rely on long-term contracts—Manufacturing Cloud uses these agreements to generate accurate quantity-based and revenue-based predictions.

? Real-Time Market & Customer Data

Any change in customer commitments automatically updates forecasts, ensuring:

- Better raw material planning

- Fewer last-minute adjustments

- More predictable production loads

? Visibility Into Partner (OEM/Distributor) Orders

Salesforce gives a 360° view of:

- Distributor demand

- OEM forecasts

- Pending order changes

This helps metal fabricators adapt quickly to downstream changes.

? Automated Forecast Adjustments

As steel or alloy pricing updates, forecasts automatically adjust to reflect:

- Updated cost models

- Margin impact

- Required production changes

4. Key Features Metal Fabricators Benefit From

Salesforce Manufacturing Cloud brings together every partner in the value chain — from field sales to OEM procurement — ensuring all parties share a single source of truth for sales, production, and pricing data.

✔ Sales Agreements Management

Track contracted volumes and pricing over time.

✔ Advanced Forecasting Workspace

Real-time projections based on sales, service, operations, and partner data.

✔ Account Manager Insights

Customer-specific forecasts, renewal trends, and order patterns.

✔ Inventory & Production Visibility (with Mulesoft/ERP Integration)

Eliminates blind spots across manufacturing operations.

5. Business Outcomes & Impact

With Salesforce Manufacturing Cloud, metal fabrication companies experience:

? 30–40% improvement in forecast accuracy

Unified data eliminates guesswork.

? 20–25% reduction in production delays

Better planning enables efficient operations.

? Optimized inventory investment

No more over-purchasing or stockouts.

⏱ Faster response to customer changes

Operational agility increases customer satisfaction.

? Better margins

Accurate forecasting lowers operational waste and reduces excess labor costs.

6. Why Metal Fabricators Need Salesforce Today

The industry is facing:

- Raw material volatility

- Higher customer expectations

- Pressure for faster turnaround times

- Need for agile decision-making

Salesforce helps metal manufacturers operate with precise, data-driven planning—not guesswork.

7. Conclusion

Accurate forecasting is the backbone of efficient metal fabrication. Salesforce Manufacturing Cloud empowers fabricators with advanced forecasting tools, contract visibility, and real-time operational insights to make smarter, more profitable decisions.

Want to implement Salesforce Manufacturing Cloud for metal fabrication?

Perigeon Software helps metal manufacturers modernize forecasting, production, and supply chain visibility.