Table of content

Introduction

The Importance of Demand-Supply Alignment

Challenges in Aligning Demand & Supply

How Salesforce Manufacturing Cloud Aligns Demand & Supply

Case Study: OEM Improves Demand-Supply Alignment with Salesforce

The Future of Demand-Supply Alignment in Machinery

Conclusion

Introduction

For machinery manufacturers, aligning demand and supply is the difference between profitability and crisis. Long production lead times and capital-intensive equipment make forecasting errors costly.

According to McKinsey (2025), misaligned demand-supply planning leads to 15–20% excess inventory costs in industrial manufacturing.

Salesforce Manufacturing Cloud provides the tools to capture dealer demand signals, align forecasts with production, and collaborate with suppliers in real time.

The Importance of Demand-Supply Alignment

- Efficiency → Avoid idle capacity and costly backlogs.

- Dealer Trust → Meet commitments with on-time delivery.

- Financial Predictability → Stabilize cash flows and investor confidence.

- Supply Chain Resilience → Proactively manage shortages.

Challenges in Aligning Demand & Supply

1. Demand Volatility in Capital Equipment

- Driven by government infrastructure budgets and commodity cycles.

- Creates boom-bust cycles.

2. Long Production Lead Times

- Machines often require 6–18 months to build.

- Delays ripple across multiple projects.

3. Lack of Real-Time Forecast Visibility

- Dealers rarely update forecasts dynamically.

- OEMs left reacting instead of planning.

4. Supplier Bottlenecks

- Key components (engines, hydraulics, semiconductors) cause bottlenecks.

5. Siloed Systems & Manual Processes

- Forecasts tracked in spreadsheets and ERP.

- No unified view.

How Salesforce Manufacturing Cloud Aligns Demand & Supply

1. Account-Based Forecasting for Granular Insights

- Forecast demand at the account/dealer level.

- Improves accuracy vs. aggregate projections.

2. Real-Time Dealer & Distributor Demand Signals

- Dealers update demand forecasts in Salesforce.

- OEMs adjust production accordingly.

3. ERP & Production Planning Integration

- Aligns Salesforce with ERP production schedules.

- Ensures factory capacity matches dealer demand.

4. Supplier Collaboration via Portals

- Suppliers access OEM forecasts and timelines.

- Reduces late deliveries and component shortages.

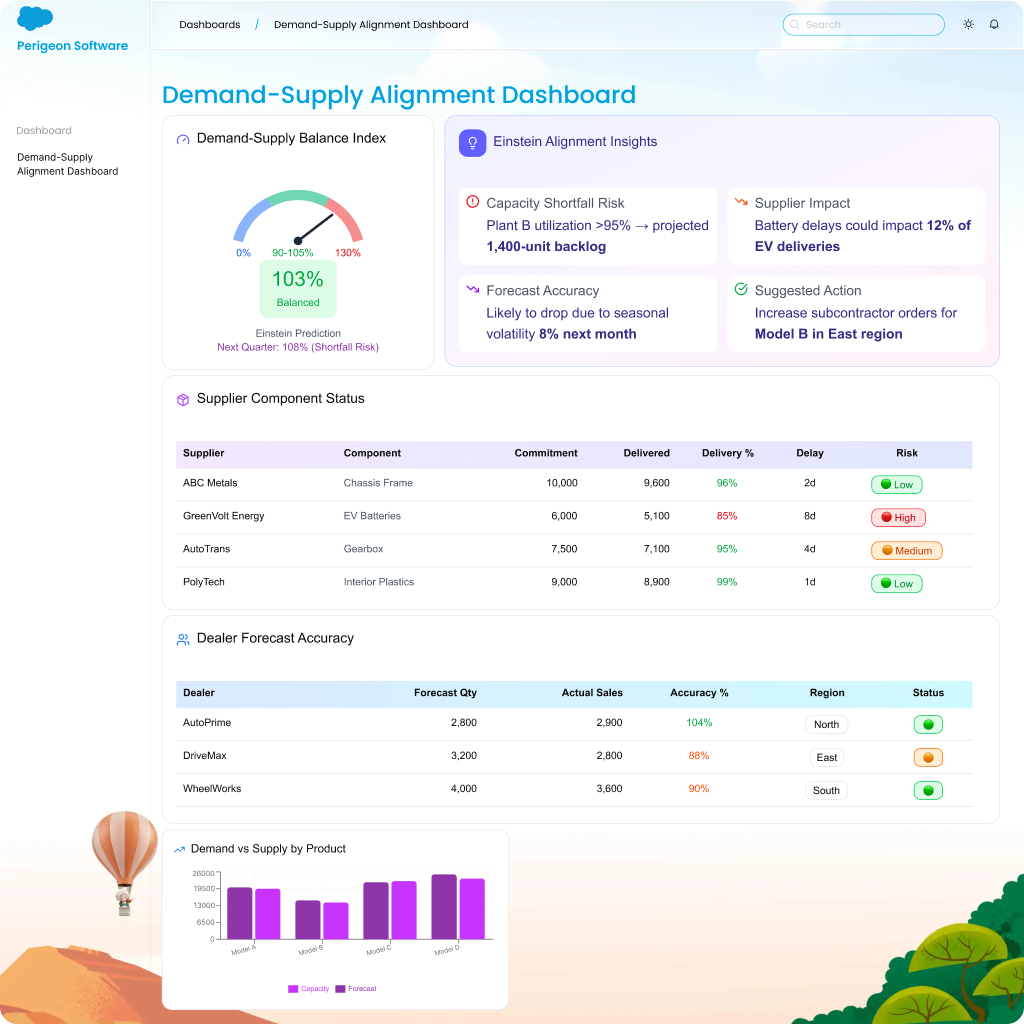

5. AI-Powered Scenario Planning

- Einstein AI models:

- Infrastructure budget changes

- Commodity price swings

- Supply chain disruptions

Case Study: OEM Improves Demand-Supply Alignment with Salesforce

A global turbine manufacturer faced:

-

- Forecast deviation of 22% annually.

- $50M tied up in excess inventory.

After Salesforce:

- Forecast accuracy improved by 25%.

- Inventory costs reduced by 15%.

- Supplier on-time delivery improved by 30%.

The Future of Demand-Supply Alignment in Machinery

- Digital Twin Production Lines → Real-time alignment with demand forecasts.

- Blockchain Supplier Collaboration → Transparent timelines and commitments.

- AI-Powered Predictive Demand → Simulating multiple macroeconomic scenarios.

Conclusion

For machinery OEMs, demand-supply alignment is essential to survive in volatile markets. Salesforce Manufacturing Cloud enables:

- Granular, account-level forecasting

- Real-time demand signals from dealers

- Seamless ERP-production alignment

- Supplier collaboration with transparency

- AI-driven scenario planning

With Salesforce, manufacturers transform demand-supply chaos into predictable, profitable growth.

⚙️ Ready to balance demand and supply in your machinery business?

? [Book a Manufacturing Cloud Strategy Session with Perigeon]