Table of content

Introduction

The Glass Manufacturing Industry Landscape

Why Forecast Accuracy Is Critical in Glass Manufacturing

Key Forecasting Challenges Faced by Glass Manufacturers

How Salesforce Manufacturing Cloud Improves Forecasting Accuracy

Case Study: Glass Manufacturer Improves Forecast Accuracy with Salesforce

The Future of Forecasting in Glass Manufacturing

Conclusion

1.Introduction

Glass manufacturing is a precision-driven, energy-intensive industry supplying critical materials to construction, automotive, pharmaceuticals, electronics, and consumer goods.

From float glass and container glass to specialty and architectural glass, manufacturers operate continuous furnaces that require long-term planning and minimal disruption. Even minor forecasting errors can result in:

- Furnace inefficiencies

- Excess inventory

- Missed customer commitments

According to McKinsey (2024), glass manufacturers experience 20–25% forecast deviation, largely due to fragmented demand signals and weak alignment between sales and production.

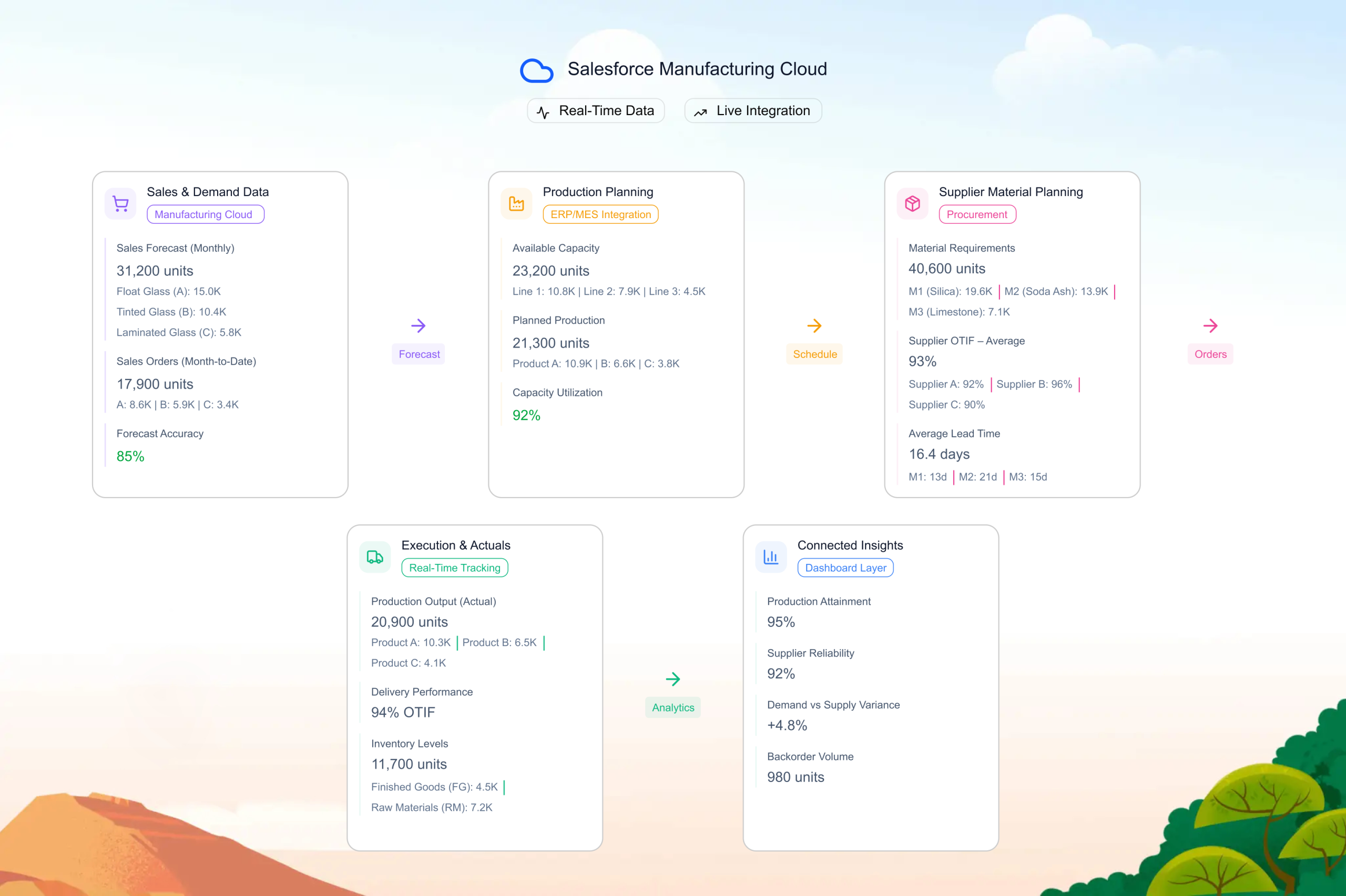

Salesforce Manufacturing Cloud enables glass manufacturers to improve forecast accuracy by unifying sales agreements, distributor demand, production planning, and AI-driven insights into a single system of truth.

The Glass Manufacturing Industry Landscape

- Major Segments:

- Float & architectural glass

- Container glass (food & beverage)

- Automotive glass

- Specialty & technical glass

- Production Model:

- Continuous furnaces

- Long batch planning cycles

- High energy dependency

- Sales Model:

- Mix of direct OEM contracts and distributor-led sales

? Forecast accuracy is essential because production cannot be stopped or restarted easily.

Why Forecast Accuracy Is Critical in Glass Manufacturing

- Furnace Stability → Incorrect forecasts disrupt continuous production

- Energy Cost Control → Overproduction wastes energy

- Inventory Optimization → Glass is bulky and costly to store

- OEM Commitments → Automotive & construction clients demand reliability

- Margin Protection → Small inefficiencies create large cost overruns

Key Forecasting Challenges Faced by Glass Manufacturers

1. Energy-Intensive Continuous Production

- Furnaces run 24×7 for months or years

- Demand misalignment leads to irreversible cost loss

2. Long Furnace & Batch Planning Cycles

- Planning cycles range from weeks to months

- Late demand changes are difficult to accommodate

3. Demand Volatility Across End Industries

- Construction, automotive, and packaging follow different cycles

- Forecasts vary drastically by segment

4. Distributor-Driven Market Signals

- Many regions rely on distributors for demand input

- OEMs lack real-time visibility into true consumption

5. Limited Visibility Across Sales & Operations

- Sales forecasts sit in CRM or spreadsheets

- Production planning runs in ERP

- No unified forecast ownership

How Salesforce Manufacturing Cloud Improves Forecasting Accuracy

1. Account- & Industry-Based Forecasting

- Forecasts by:

- Customer

- Industry segment

- Region

- Improves accuracy versus aggregate forecasting

2. Sales Agreement–Driven Demand Commitments

- Links customer contracts and long-term commitments directly to forecasts

- Ensures production aligns with committed, not speculative, demand

3. ERP & Production Planning Integration

- Integrates Salesforce with ERP/MES systems

- Aligns furnace capacity, batch schedules, and material planning

4. Distributor & OEM Forecast Collaboration

- Distributors update demand forecasts via Experience Cloud portals

- OEMs gain near real-time market signals

5. AI-Powered Demand Sensing & Risk Alerts

- Einstein AI analyzes:

- Historical demand

- Construction & automotive trends

- Seasonal packaging demand

- Flags forecast risks early

Case Study: Glass Manufacturer Improves Forecast Accuracy with Salesforce

A regional container glass manufacturer supplying food & beverage clients faced:

- 27% forecast deviation

- Overstocked slow-moving SKUs

- Furnace inefficiencies during demand dips

After Salesforce Manufacturing Cloud:

- Forecast accuracy improved by 26%

- Inventory holding costs reduced by 18%

- Furnace utilization stabilized across quarters

The Future of Forecasting in Glass Manufacturing

- AI-Driven Furnace Planning → Aligning melt rates with demand forecasts

- Digital Twin Furnaces → Simulating demand vs. production capacity

- IoT-Integrated Demand Signals → Real-time consumption feedback

- Sustainability Forecasting → Energy and carbon-aware planning

Conclusion

Accurate forecasting is not optional in glass manufacturing — it’s mission-critical. Salesforce Manufacturing Cloud enables:

- Contract-driven demand forecasting

- Distributor-aligned market visibility

- ERP-integrated production planning

- AI-powered early risk detection

With Salesforce, glass manufacturers shift from reactive planning to predictable, cost-efficient operations.

Ready to improve forecasting accuracy in glass manufacturing?

? Book a Manufacturing Cloud Strategy Session with Perigeon