Table of content

Introduction

Why Collaboration Challenges Persist in Rubber Manufacturing

The Cost of Poor Communication Between Distributors & OEMs

How Salesforce Manufacturing Cloud Enables Seamless Collaboration

Case Example: Collaboration Transformation with Perigeon Software

Business Benefits of Enhanced Partner Collaboration

Why Choose Perigeon Software as Your Salesforce Partner

Conclusion

? Introduction

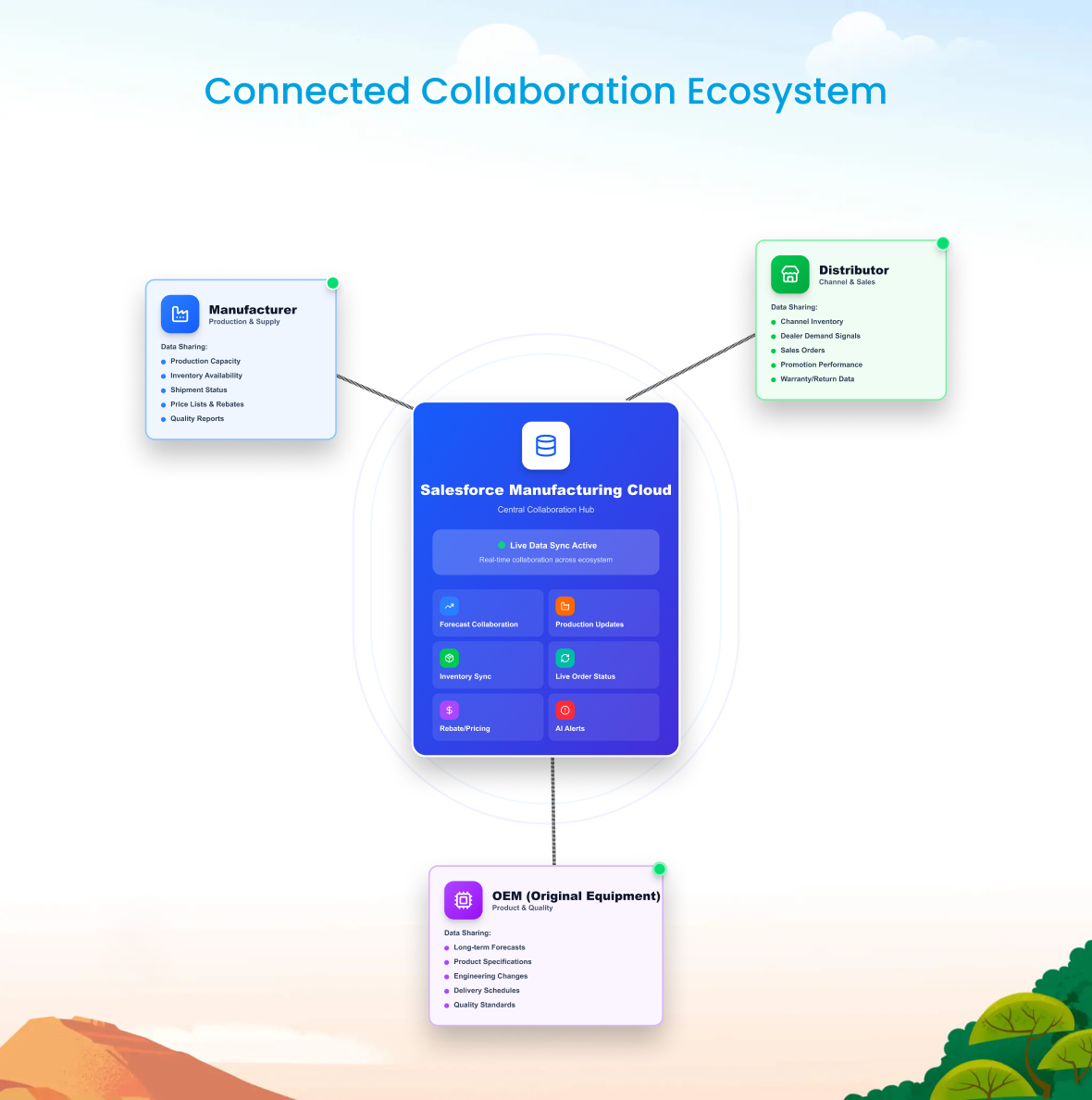

In rubber product manufacturing, the business ecosystem is deeply interconnected — manufacturers, distributors, and OEM customers (Original Equipment Manufacturers) must work in perfect sync to manage large-scale supply chains.

From automotive components to industrial hoses, rubber parts flow through multiple hands before reaching the end customer. Yet, despite being a highly integrated industry, most collaboration remains manual, email-driven, and data-fragmented.

This leads to:

- Delayed communication between distributors and OEMs.

- Missed forecast updates.

- Inconsistent pricing and rebate data.

Salesforce Manufacturing Cloud solves this by connecting every stakeholder — from internal sales teams to external distributors and OEMs — on a unified, transparent, and real-time platform.

Connected Collaboration Ecosystem: Visual showing Salesforce Manufacturing Cloud connecting manufacturer, distributor, and OEM with live data exchange.

⚙️ Why Collaboration Challenges Persist in Rubber Manufacturing

Rubber manufacturing operates in multi-tiered supply chains, where each partner — OEM, distributor, or fabricator — contributes differently.

Yet, communication often fails because:

- Data resides in multiple systems (CRM, ERP, spreadsheets).

- Distributors lack access to accurate order status or inventory data.

- OEMs have limited visibility into supplier capacity or lead times.

- Sales agreements and pricing structures vary by partner type.

This fragmentation results in forecast mismatches, inventory build-ups, and revenue leakage.

? The Cost of Poor Communication Between Distributors & OEMs

Let’s quantify the problem:

Pain PointBusiness ImpactDelayed ForecastsProduction over/under schedulingPrice InconsistenciesContract disputes & margin lossManual Order TrackingSlower fulfillment cyclesLack of VisibilityPoor demand predictabilityRebate MismanagementFinancial inaccuracies

The Cost of Poor Communication Between Distributors & OEM

Let’s quantify the problem:

| Pain Point | Business Impact |

|---|---|

| Delayed Forecasts | Production over/under scheduling |

| Price Inconsistencies | Contract disputes & margin loss |

| Manual Order Tracking | Slower fulfillment cycles |

| Lack of Visibility | Poor demand predictability |

| Rebate Mismanagement | Financial inaccuracies |

According to a Deloitte survey, inefficient distributor-OEM collaboration can cost manufacturers up to 15% of annual revenue through lost opportunities and operational inefficiency.

? How Salesforce Manufacturing Cloud Enables Seamless Collaboration

Salesforce Manufacturing Cloud brings together every partner in the value chain — from field sales to OEM procurement — ensuring all parties share a single source of truth for sales, production, and pricing data.

Here’s how:

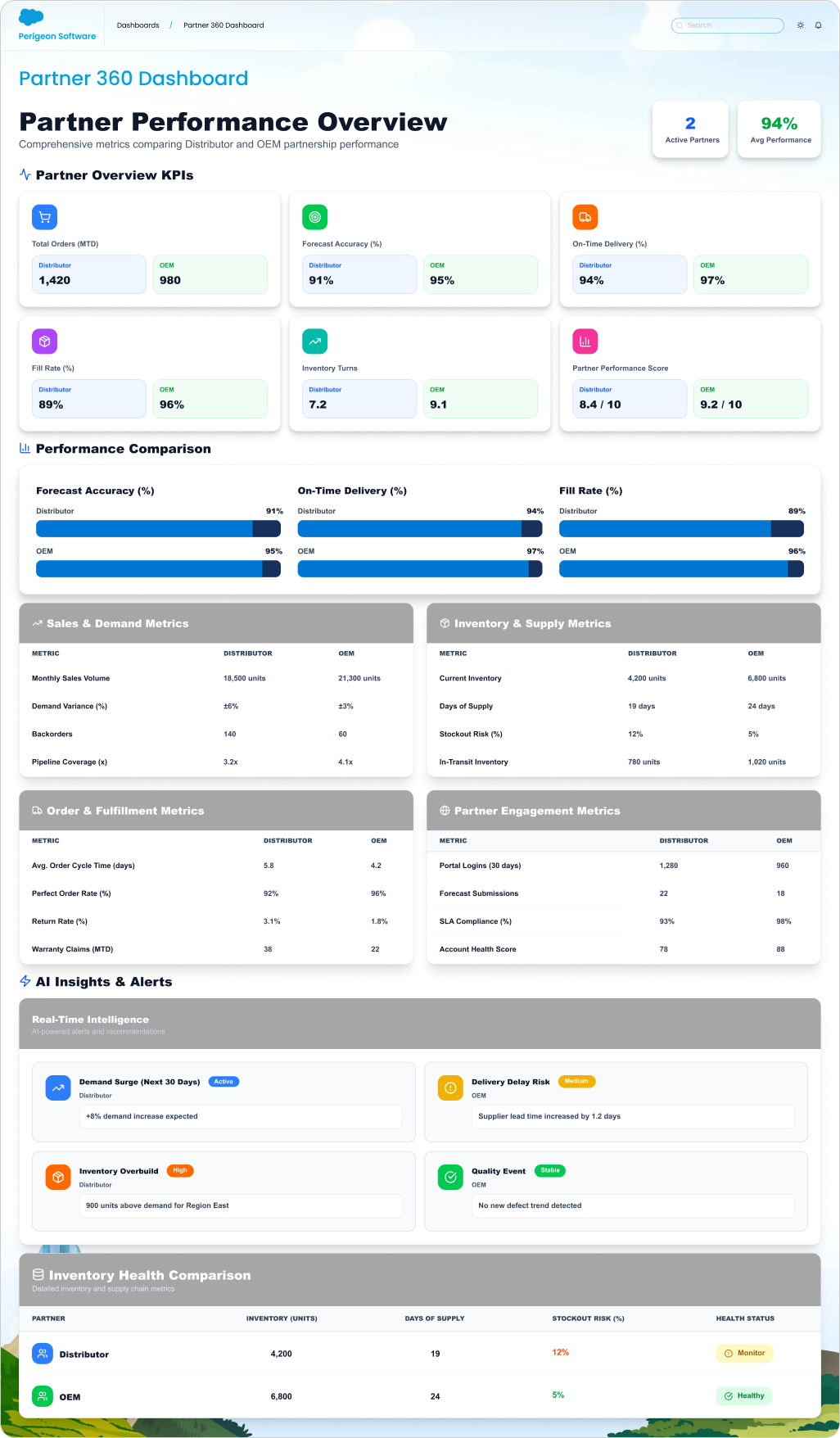

1️⃣ Centralized Partner Data Management

Manufacturing Cloud consolidates all partner information — contracts, pricing, forecasts, and performance — in one location.

Distributors and OEMs can securely access:

- Current and historical orders.

- Product specifications.

- Custom pricing or rebate structures.

- Inventory availability and shipment details.

Partner 360 Dashboard: Salesforce dashboard showing real-time distributor and OEM performance metrics.

2️⃣ Real-Time Order & Forecast Visibility

OEMs often adjust orders based on their production cycles, while distributors manage large inventories to buffer demand.

With Salesforce, both can see real-time demand forecasts and order statuses — eliminating the lag between customer demand and production updates.

For Manufacturers:

- Improved production scheduling accuracy.

- Faster response to demand fluctuations.

For Distributors & OEMs:

- Transparent view of order status.

- Better planning of procurement and delivery cycles.

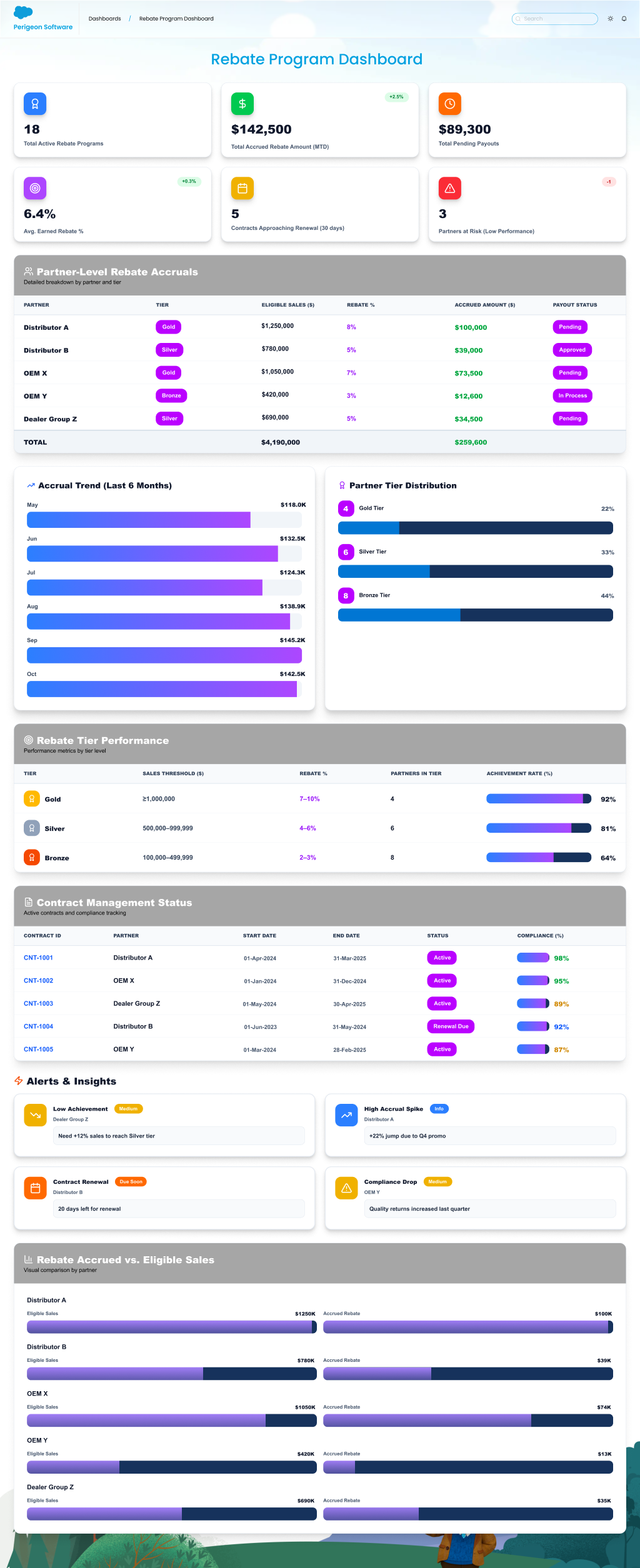

3️⃣ Contract & Rebate Transparency

Rubber manufacturers frequently offer complex volume-based pricing and rebate programs for distributors and OEMs.

Salesforce Manufacturing Cloud ensures:

- Every stakeholder sees accurate, contract-based pricing.

- Rebate eligibility and accruals are visible in real time.

- Finance and sales teams stay aligned on payout accuracy.

This transparency builds trust and reduces disputes — a major factor in improving long-term partner relationships.

Rebate Program Dashboard: Visual of rebate tracking and contract management screen in Salesforce.

4️⃣ Automated Communication Workflows

Instead of relying on manual email chains, Salesforce automates notifications and updates for:

- New order confirmations.

- Delivery schedule changes.

- Rebate milestones.

- Pricing updates.

These automated workflows reduce administrative workload by 35–40%, freeing teams to focus on strategic partner management.

? Case Example: Collaboration Transformation with Perigeon Software

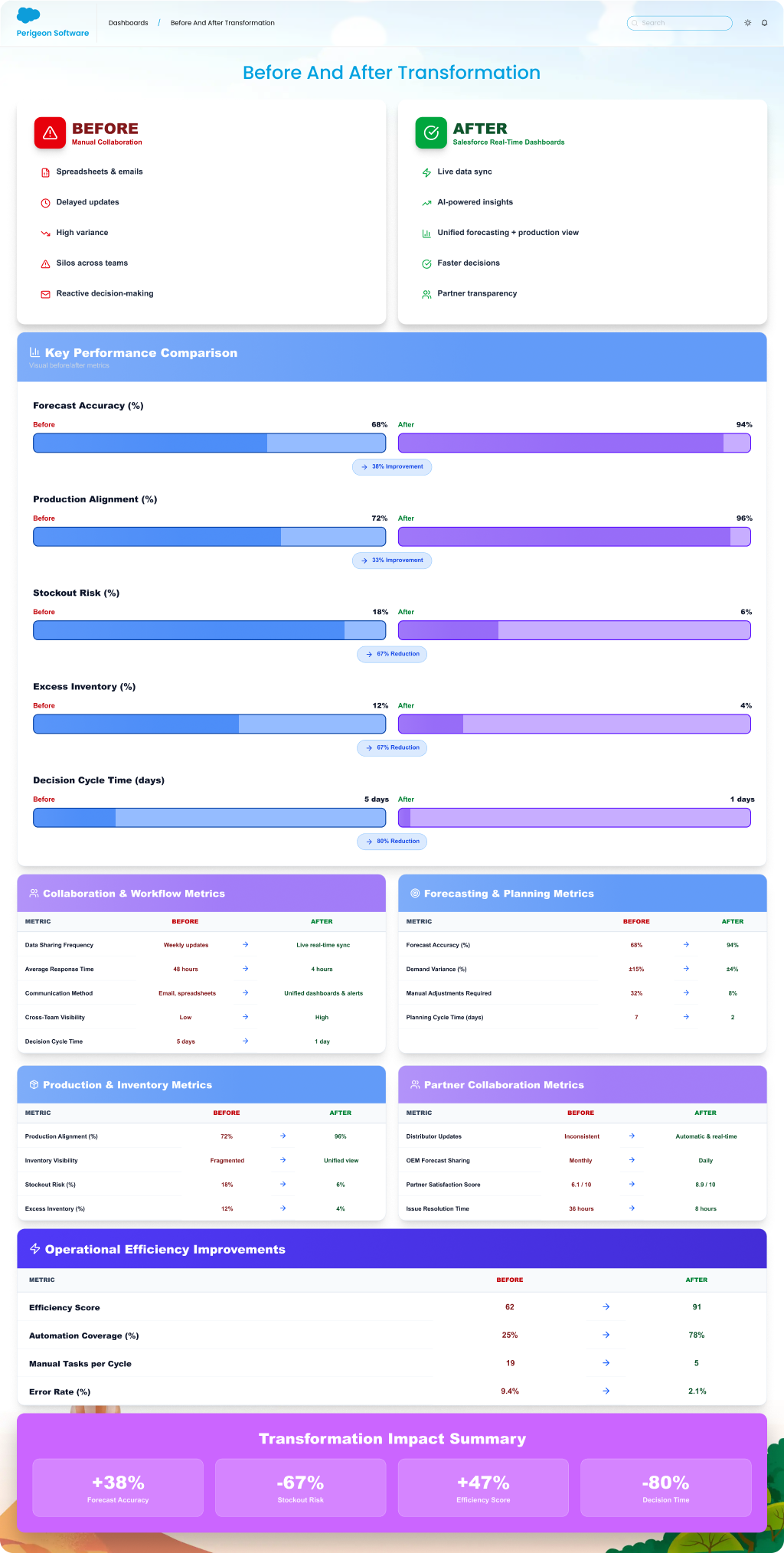

Challenge:

A mid-sized industrial rubber component manufacturer supplied to multiple automotive OEMs and regional distributors. Their collaboration relied on spreadsheets and phone calls, leading to forecast mismatches and missed rebate payments.

Perigeon Software Solution:

- Implemented Salesforce Manufacturing Cloud with partner visibility portals.

- Automated contract and pricing updates across all partners.

- Integrated OEM and distributor data streams into a unified forecasting model.

Results:

- Forecast accuracy improved by 38%.

- Order processing time reduced by 45%.

- Partner satisfaction scores increased by 50%.

Before and After Transformation: Split image comparing manual collaboration vs Salesforce-powered real-time dashboards.

? Business Benefits of Enhanced Partner Collaboration

Benefit AreaOutcomeForecast AccuracyImproved by 35–45%Order Fulfillment SpeedReduced lead times by 40%Rebate Accuracy100% visibility for partnersPartner Satisfaction50%+ improvementAdministrative CostLowered by 30%

Business Benefits of Enhanced Partner Collaboration

| Benefit Area | Outcome |

|---|---|

| Forecast Accuracy | Improved by 35–45% |

| Order Fulfillment Speed | Reduced lead times by 40% |

| Rebate Accuracy | 100% visibility for partners |

| Partner Satisfaction | 50%+ improvement |

| Administrative Cost | Lowered by 30% |

Result: Stronger distributor and OEM relationships, better supply chain visibility, and higher operational agility.

? Why Choose Perigeon Software as Your Salesforce Partner

At Perigeon Software, we help manufacturers unlock the full potential of Salesforce Manufacturing Cloud through tailored solutions for partner management and collaboration.

Our expertise includes:

- Partner portal configuration for OEMs & distributors.

- Contract, rebate, and pricing automation.

- Forecast synchronization with ERP & production systems.

- AI-powered analytics for performance tracking.

Whether you manage 10 or 1000 distributors, we ensure your Salesforce ecosystem delivers measurable ROI.

? Conclusion

Distributor and OEM collaboration isn’t just about communication — it’s about data trust, shared visibility, and operational alignment.

With Salesforce Manufacturing Cloud, rubber manufacturers can:

- Eliminate silos.

- Improve forecasting accuracy.

- Build stronger, data-driven partnerships.

Partner with Perigeon Software to create a connected manufacturing ecosystem where every stakeholder thrives.