Table of content

Introduction

Why Long-Term Contracts Are Critical in Steel Manufacturing

Challenges Steel Manufacturers Face in Managing Long-Term Agreements

How Salesforce Manufacturing Cloud Streamlines Contract Management

Key Features Beneficial for Steel Contract Optimization

Real-World Outcomes for Steel Manufacturers

Why Now Is the Time to Digitize Contract Management

Conclusion

If you’re ready to modernize long-term contract management for your steel manufacturing operations

1.Introduction

Steel manufacturing is an industry defined by high volumes, long production cycles, and contract-driven sales. Most steel producers work with long-term customer agreements that include locked pricing, volume commitments, rebate programs, and periodic renegotiations.

- Managed manually

- Spread across spreadsheets and PDFs

- Prone to errors or misaligned commitments

- Disconnected from production and forecasting data

Salesforce Manufacturing Cloud eliminates these issues by providing a centralized contract and forecasting engine tailored for steel companies.

2. Why Long-Term Contracts Are Critical in Steel Manufacturing

Steel manufacturers rely heavily on contracts when dealing with:

- Automotive OEMs

- Heavy machinery producers

- Construction and infrastructure contractors

- Raw material distributors

- International buyers

Long-term contracts guarantee:

- Volume stability

- Predictable revenue

- Reliable production planning

- Better material procurement decisions

Yet, these benefits only work if the contracts are accurately tracked, consistently monitored, and fully visible across teams.

3. Challenges Steel Manufacturers Face in Managing Long-Term Agreements

❗ Frequent Pricing Volatility

Steel prices fluctuate based on:

- Raw material availability

- Energy costs

- Market demand

- Global supply chain shifts

Managing these changes manually creates revenue leakage.

❗ Complex Volume Commitments

Contracts include monthly, quarterly, or yearly volume allocations — often updated frequently.

❗ Lack of Sales–Production Alignment

Sales locks volumes, but production may not have material or machine availability.

❗ Limited Visibility Into Customer Changes

Customers often adjust orders last minute, creating scheduling disruptions.

❗ Manual Rebate and Discount Tracking

Incorrect rebate calculations lead to lost margins and unhappy customers.

4. How Salesforce Manufacturing Cloud Streamlines Contract Management

? Sales Agreements Management

This is the core feature steel manufacturers rely on.

Manufacturing Cloud allows teams to:

- Create standardized digital contracts

- Track volume and pricing commitments

- Monitor consumed vs. committed quantities

- Adjust terms dynamically

- Sync agreements with ERP and finance systems

? Real-Time Forecasting Linked to Contracts

As contract terms change, forecasts update automatically, keeping:

- Sales

- Finance

- Operations

- Production planning

? Automated Change Tracking

Steel customers frequently adjust volumes — Salesforce provides:

- Version control

- Automated amendments

- Real-time notifications

- Collaborative approval workflows

No more lost emails or outdated spreadsheets.

? Rebate & Margin Visibility

Manufacturing Cloud helps steel companies automate:

- Tiered rebates

- Incentive calculations

- Profit margin analysis

- Customer profitability scoring

This reduces financial leakage significantly.

? 360° Customer Contract Insights

Every stakeholder gets access to:

- Contract history

- Pending renewals

- Performance analytics

- Renewal recommendations

This strengthens long-term customer relationships.

5. Key Features Beneficial for Steel Contract Optimization

✔ Sales Agreement Workspace

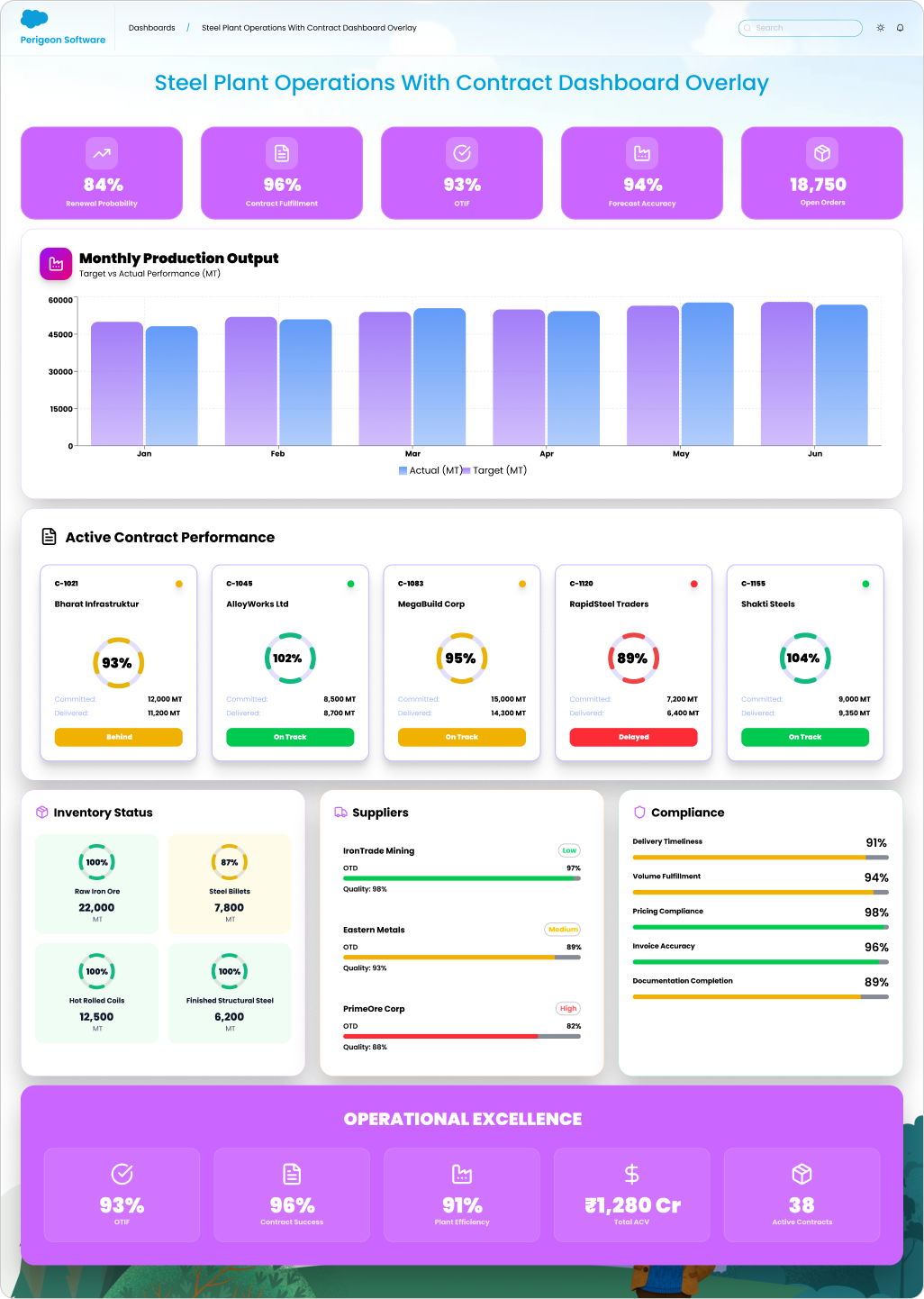

Tracks real-time performance of each contract against targeted KPIs.

✔ Forecast Adjustment Engine

Forecasts update instantly when prices, volumes, or schedules change.

✔ Partner Collaboration Tools

Distributors, OEMs, and large buyers can collaborate through Experience Cloud.

✔ ERP & SAP Integration

Ensures clean, accurate data flows between Salesforce and core production systems.

✔ Revenue Optimization

Predictive analytics highlight high-value customers and at-risk agreements.

6. Real-World Outcomes for Steel Manufacturers

Steel producers using Salesforce Manufacturing Cloud have seen:

? 35% reduction in contract-related errors

Due to automated versioning and real-time updates.

? 25% better forecast accuracy

With contract-linked forecasting.

⏳ 40% faster contract negotiation cycles

Thanks to digital workflows.

? 10–15% margin improvement

Through better rebate tracking and pricing visibility.

? Stronger long-term customer relationships

With transparent, accurate data sharing.

7. Why Now Is the Time to Digitize Contract Management

The steel industry is impacted by:

- Rapid market price fluctuations

- Increased global competition

- Higher expectations from OEMs

- Pressure for traceability and transparency

Digital transformation with Salesforce is no longer optional.

It’s a competitive advantage.

8. Conclusion

Long-term contracts are the backbone of steel manufacturing — but only when managed accurately and efficiently. Salesforce Manufacturing Cloud empowers steel producers with centralized contract management, automated forecasting, real-time tracking, and strong customer collaboration.

This leads to:

- Better profitability

- Reduced operational risk

- Consistent production planning

- Strong, reliable customer partnerships

If you’re ready to modernize long-term contract management for your steel manufacturing operations

If you’re ready to modernize long-term contract management for your steel manufacturing operations, Perigeon Software can help you implement and customize Salesforce Manufacturing Cloud.