Table of content

Introduction

The Retail Forecasting Challenge in Footwear Manufacturing

The Cost of Inaccurate Forecasts

Why Salesforce Manufacturing Cloud Is a Game-Changer

How Salesforce Improves Retail Forecast Accuracy

Case Study: How a Global Footwear Brand Improved Forecast Accuracy with Salesforce

Measurable Business Impact

Future of Footwear Forecasting with AI & Data Integration

Why Partner with Perigeon Software

Conclusion

? Introduction

Footwear manufacturing sits at the intersection of fashion trends, seasonal cycles, and shifting retail demand.

Manufacturers face a unique challenge — producing the right quantity of the right design at the right time, across multiple markets and channels.

Yet, many footwear companies still rely on fragmented systems and manual forecasting methods that fail to keep pace with today’s fast-changing retail environment.

Salesforce Manufacturing Cloud is transforming how footwear manufacturers manage retail forecasts, connecting data across sales, distribution, and production — enabling data-driven decisions, faster response times, and higher profitability.

“In the footwear industry, success depends not only on design and quality — but on forecasting precision.”

? The Retail Forecasting Challenge in Footwear Manufacturing

Footwear manufacturers often juggle:

- Multiple SKUs (sizes, styles, materials)

- Diverse channels (retail, e-commerce, wholesale)

- Volatile demand (influenced by fashion, weather, and sports trends)

Each product line comes with different lifecycle lengths, pricing strategies, and distribution models.

Without accurate forecasting, manufacturers struggle with either excess inventory or stockouts, both of which hurt margins and brand reputation.

Key challenges include:

- Disconnected sales and production data

- Manual spreadsheet-based forecasting

- Limited visibility into retail sell-through data

- Poor communication between production and sales teams

- Reactive rather than proactive decision-making

? The Cost of Inaccurate Forecasts

Footwear demand is often driven by unpredictable factors — celebrity endorsements, sports events, fashion cycles, and even weather.

According to industry research:

- Forecast inaccuracies can lead to 20–30% excess inventory across product lines.

- Retail markdowns due to misaligned forecasts cost brands up to 10% of annual revenue.

- Manufacturers operating with disconnected data systems lose 15–20% operational efficiency.

These inefficiencies compound when manufacturers rely on outdated forecasting systems not integrated with retailer or distributor networks.

? Why Salesforce Manufacturing Cloud Is a Game-Changer

Salesforce Manufacturing Cloud provides a unified platform that connects sales forecasts, production planning, and retail demand — allowing manufacturers to anticipate, plan, and execute with precision.

It aligns sales and operations through shared visibility, intelligent analytics, and collaborative forecasting tools — so every stakeholder, from supplier to retailer, operates from the same data-driven truth.

? How Salesforce Improves Retail Forecast Accuracy

1️⃣ Unified Data for Demand Planning

Manufacturing Cloud consolidates sales agreements, order history, and retailer demand into a single source of truth.

Manufacturers gain access to:

- Real-time sales data from retail partners

- Historical buying patterns by channel and region

- Upcoming order commitments and pipeline visibility

This unified view helps align production with true retail demand, reducing costly overproduction or stock shortages.

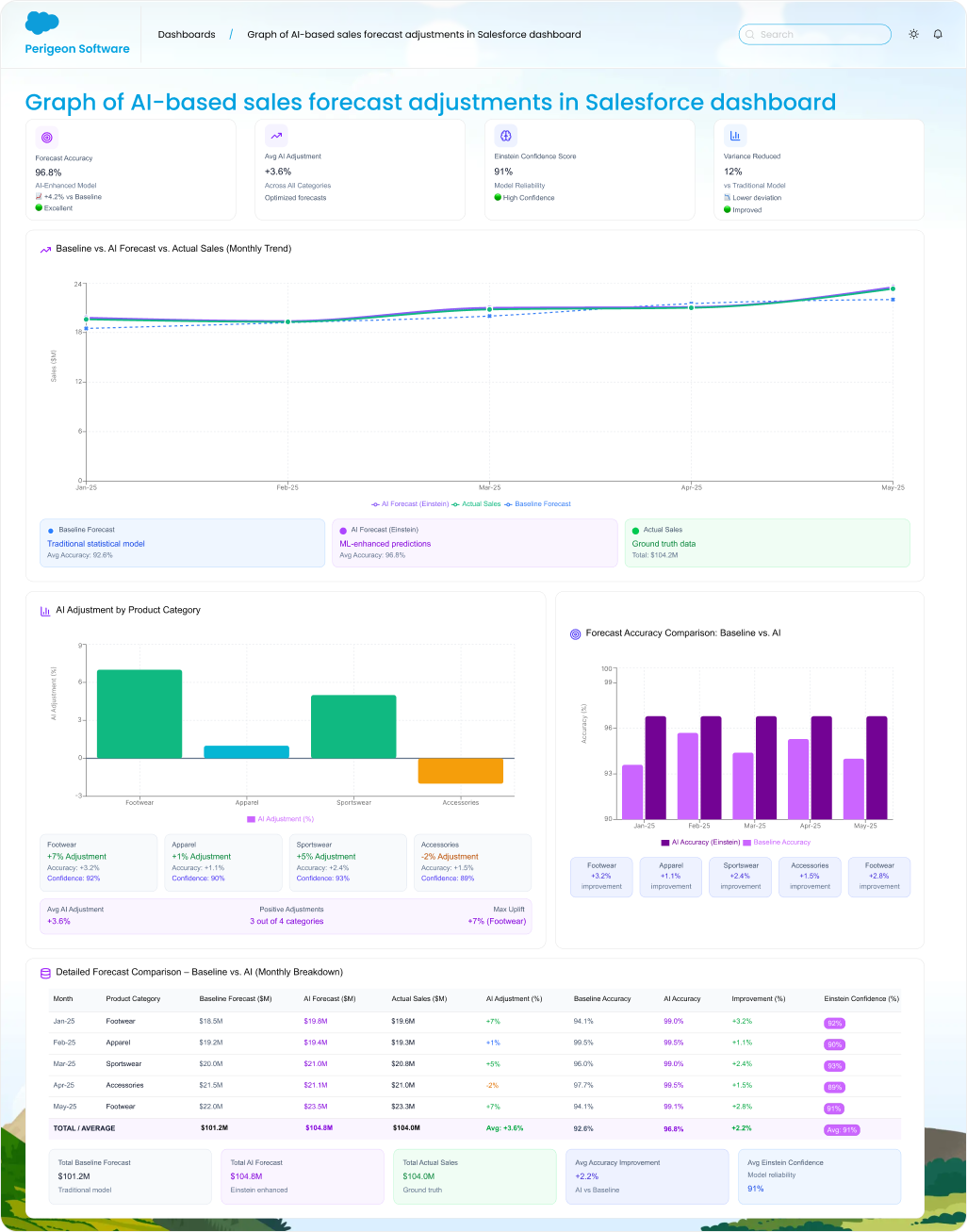

2️⃣ AI-Powered Forecasting & Predictive Insights

Using Salesforce Einstein AI, Manufacturing Cloud applies machine learning models that continuously refine forecasts based on new data.

For footwear, this means:

- Predicting demand shifts by region, season, or trend

- Adjusting inventory and production plans dynamically

- Running “what-if” simulations for new product launches

Example: Einstein might predict a 15% demand increase in athletic shoes ahead of a sports event — allowing manufacturers to ramp up production proactively.

3️⃣ Enhanced Retail Collaboration

Footwear brands often rely on multiple retailers and distributors across global markets.

Salesforce Experience Cloud enables these retail partners to:

- Submit forecasts directly via digital portals

- Track orders and fulfillment in real time

- Provide feedback on sell-through and returns

This shared digital workspace ensures all stakeholders — manufacturers, distributors, and retailers — work in lockstep alignment.

4️⃣ Real-Time Visibility Across the Supply Chain

With Salesforce’s 360° view, manufacturers can monitor production progress, supplier readiness, and retailer demand simultaneously.

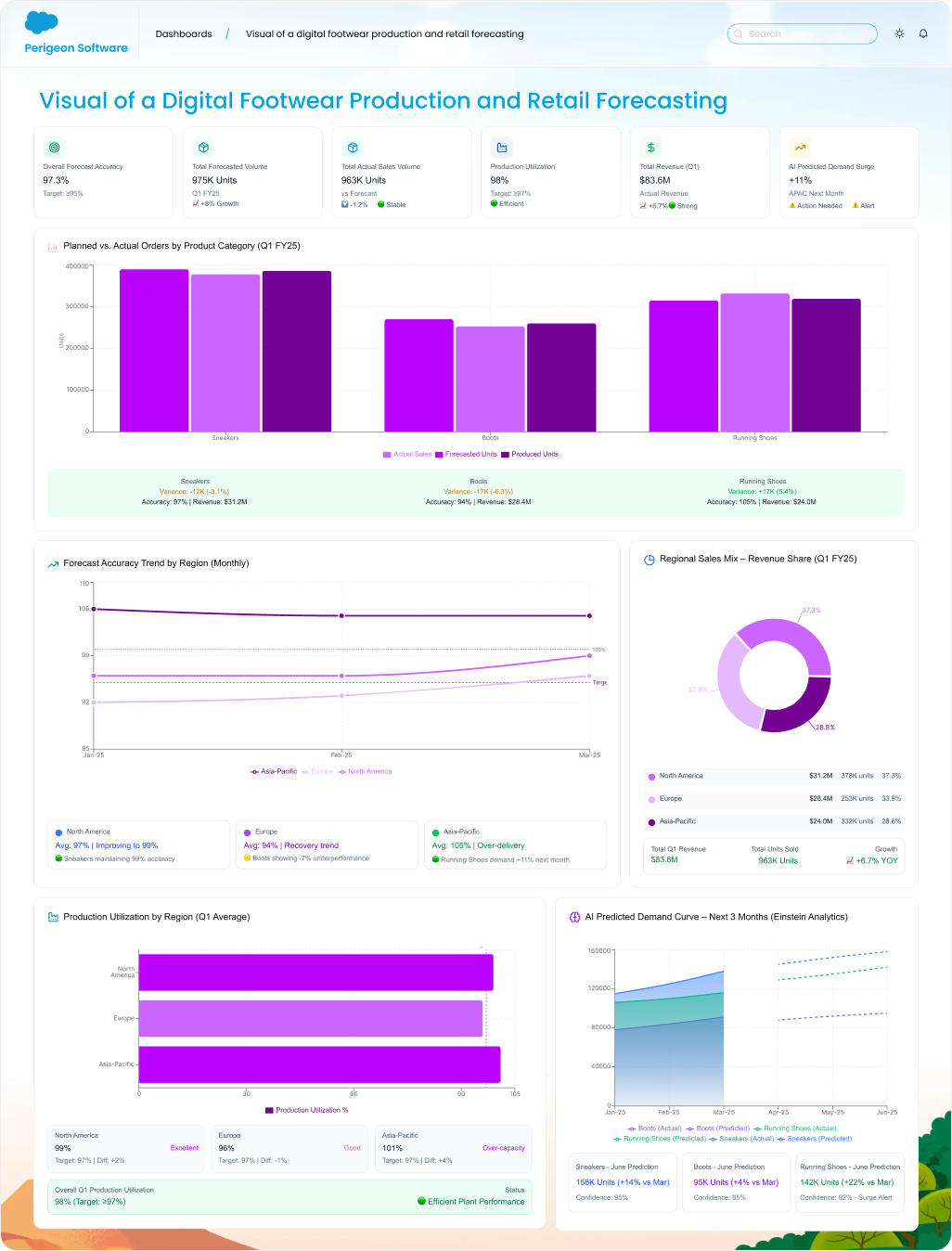

Integrated dashboards display:

- Current stock levels

- Retail sell-through performance

- Material availability and supplier status

This transparency helps decision-makers respond instantly to changes — for example, reassigning production to meet a surge in retail orders from a specific region.

5️⃣ Scenario Planning & Agile Production Alignment

Manufacturing Cloud supports scenario planning to evaluate outcomes based on different demand curves.

Manufacturers can simulate:

- New product launch performance

- Seasonal promotions or clearance impacts

- Supply disruptions or raw material constraints

These insights guide production planning and capacity allocation, helping ensure that every batch produced aligns with forecasted retail opportunities.

? Case Study: How a Global Footwear Brand Improved Forecast Accuracy with Salesforce

Scenario:

A global footwear company managing multiple retail partnerships across North America and Europe struggled with inaccurate forecasts and delayed production alignment.

Challenges:

- Disconnected retailer data and siloed sales systems

- High markdown rates on unsold inventory

- Slow forecast updates due to manual processes

Solution Implemented by Perigeon Software:

- Salesforce Manufacturing Cloud integrated with retailer sales systems

- Einstein AI for predictive forecasting

- Real-time dashboards for order tracking and stock movement

Results:

- Forecast accuracy improved by 32% within six months

- Inventory carrying costs reduced by 25%

- Production planning lead time shortened by 40%

- On-time retail fulfillment increased to 98%

? Measurable Business Impact

Manufacturers leveraging Salesforce Manufacturing Cloud typically report:

- 30–40% improvement in forecast accuracy

- 20–25% faster production response time

- 15–20% higher retail order fill rates

- 10–12% reduction in logistics and holding costs

These metrics demonstrate how data-driven forecasting directly drives profitability in footwear manufacturing.

? Future of Footwear Forecasting with AI & Data Integration

As the footwear market evolves, forecasting will become AI-enhanced, omnichannel-driven, and sustainability-focused.

Upcoming Salesforce innovations will enable:

- Real-time retail data ingestion from POS systems

- Predictive inventory balancing across stores and warehouses

- Carbon footprint tracking for production and logistics

- Demand sensing powered by social and trend analytics

The future isn’t just about predicting demand — it’s about creating a responsive, intelligent, and ethical supply chain.

? Why Partner with Perigeon Software

Perigeon Software, a Salesforce Consulting Partner, helps footwear manufacturers unlock the full value of Manufacturing Cloud through:

- Custom forecasting dashboards for footwear SKUs

- Retailer and distributor integration

- AI-driven forecast automation using Einstein Analytics

- ERP, PLM, and inventory system integration

- Post-deployment optimization and analytics support

With Perigeon, footwear brands achieve operational agility, predictive intelligence, and supply chain harmony.

? Conclusion

Retail forecasting in footwear manufacturing has evolved from intuition to intelligence.

By combining Salesforce Manufacturing Cloud and AI-powered analytics, manufacturers gain real-time insight into demand, supply, and retail performance — ensuring agility, accuracy, and profitability.

With Perigeon Software as your Salesforce implementation partner, your brand can step confidently into the future — where every forecast is precise, and every sale is planned for success.