Table of content

Introduction

Why Forecasting Matters in Automotive Manufacturing

Challenges in Automotive Demand Forecasting

How Salesforce Manufacturing Cloud Transforms Forecasting

Case Study: Forecast Accuracy in Automotive with Salesforce

The Future of Forecasting in Automotive Manufacturing

Conclusion

Introduction

Automotive manufacturing is a high-stakes industry where forecast accuracy defines profitability. A 2024 Statista report revealed that global auto manufacturers lose nearly $100 billion annually due to mismatched supply and demand. Overproduction leads to inventory pile-ups, while underproduction causes missed sales opportunities.

Forecasting is particularly complex in today’s automotive sector: the rise of EVs, fluctuating fuel prices, global supply chain shocks, and shifting customer preferences all disrupt traditional models.

This is where Salesforce Manufacturing Cloud reshapes the game. By providing account-level forecasting, AI-driven analytics, and real-time dealer insights, it transforms automotive forecasting from a guessing game into a science.

Why Forecasting Matters in Automotive Manufacturing

Demand forecasting directly impacts:

- Production Planning → Aligning vehicle models with market demand.

- Inventory Optimization → Avoiding excess stock or backorders.

- Dealer Satisfaction → Ensuring timely delivery against commitments.

- Revenue Predictability → Providing accurate guidance to investors and stakeholders.

For automotive OEMs, accurate forecasting means:

- Higher margins (5–10% uplift according to PwC)

- Lower working capital tied up in unsold inventory

- Dealer Satisfaction → Ensuring timely delivery against commitments.

- Improved dealer trust through reliable supply

Inaccurate forecasts, on the other hand, erode competitiveness and brand reputation.

Challenges in Automotive Demand Forecasting

Despite its importance, forecasting in automotive remains riddled with challenges.

1. Market Volatility & EV Adoption

- Rapid EV growth disrupts traditional demand patterns.

- Hybrid vs. ICE (internal combustion engine) demand is region-dependent.

- Unpredictable policy changes (e.g., EV tax credits, emission standards).

2. Regional Demand Variability

- Strong EV adoption in California vs. slower uptake in Midwest states.

- Europe vs. U.S. vs. Asia — demand cycles vary by geography.

- Seasonal spikes (e.g., holiday sales in North America).

3. Siloed Data & Legacy Forecasting Tools

- Many OEMs still rely on Excel-based forecasting.

- ERP data doesn’t integrate with dealer signals.

- No standardized platform for collaboration.

4. Dealer & Distributor Uncertainty

- Dealers provide commitments but lack visibility into production schedules.

- Incentives and rebates distort actual demand signals.

- No standardized platform for collaboration.

5. Supply Chain Constraints

- Semiconductor and battery shortages skew forecasts.

- Long lead times make realignment difficult.

- Lack of predictive analytics to identify risks.

How Salesforce Manufacturing Cloud Transforms Collaboration

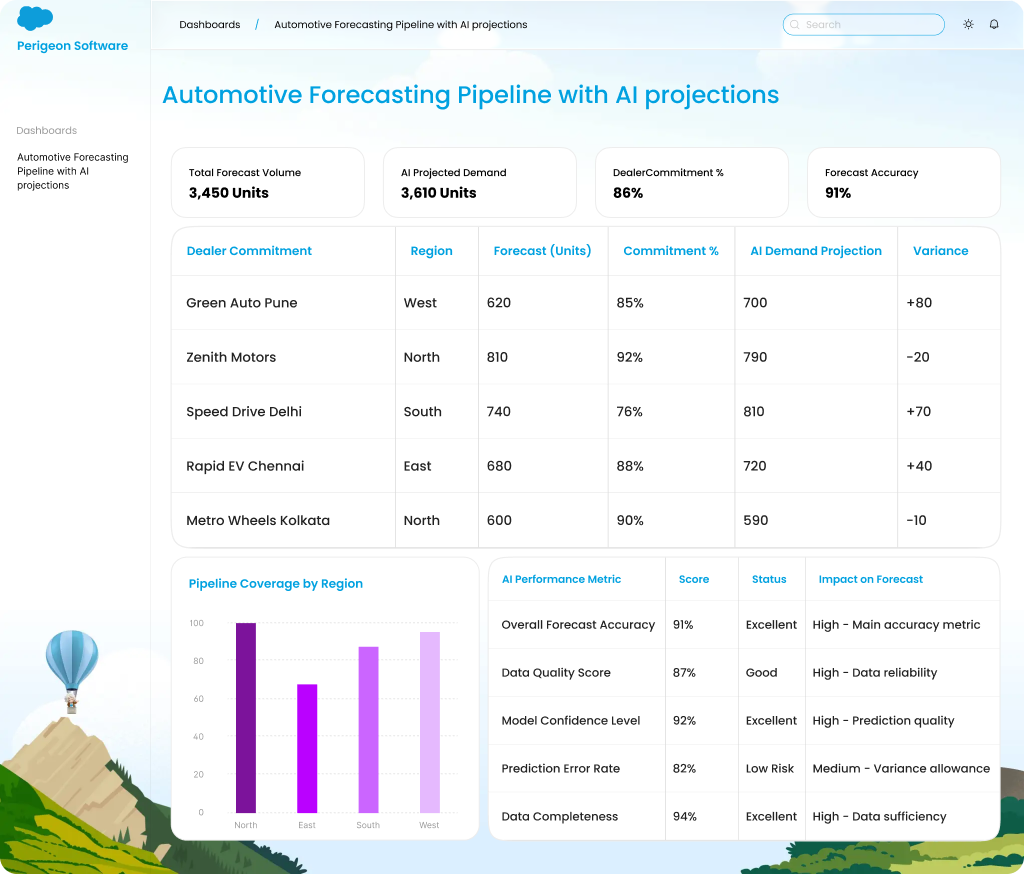

Salesforce Manufacturing Cloud directly addresses these challenges with powerful features designed for accuracy, agility, and trust.

1. Account-Based Forecasting → Granular Demand Accuracy

- Moves from top-down to bottom-up forecasting.

- Provides dealer-specific demand projections.

- Tracks commitments vs. actual orders at the account level.

? Example: An OEM can see that Dealer X is trending 15% below their EV commitment and adjust production accordingly.

2. AI-Powered Predictive Analytics → Smarter Projections

- Einstein AI refines forecasts using:

- Market signals

- Dealer history

- Seasonal demand patterns

- Macroeconomic data

- Adjusts forecasts dynamically as new data streams in.

? Statistic: McKinsey research suggests AI forecasting improves accuracy by 20–50% compared to traditional methods.

3. Real-Time Data Integration Across Systems

- Connects Salesforce with ERP, CRM, and supply chain systems.

- Provides a unified forecasting view across finance, operations, and sales.

- Eliminates delays caused by siloed systems.

4. Dealer & Distributor Demand Signal Capture

- Dealers update commitments via Experience Cloud portals.

- OEMs gain real-time insight into regional demand shifts.

- Improves trust by giving dealers visibility into forecast progress.

? Example: If EV adoption accelerates in a metro area, dealer adjustments instantly feed into OEM forecasts.

5. Scenario Planning & “What-If” Modeling

- Simulate multiple scenarios (e.g., raw material shortage, EV tax credit changes).

- Model impact on production schedules and revenue.

- Enables proactive decision-making instead of reactive scrambling.

Case Study: Forecast Accuracy in Automotive with Salesforce

A European automotive OEM faced:

-

- Forecast deviation of 22% year-on-year.

- Frequent dealer disputes over allocation.

After implementing Salesforce Manufacturing Cloud:

- Forecast accuracy improved to 95% (from 78%).

- Dealer satisfaction scores rose 30%.

- Inventory carrying costs were reduced by 12%.

? This demonstrates how granular, account-driven forecasting drives not just accuracy but also profitability.

The Future of Forecasting in Automotive Manufacturing

Forecasting in automotive will evolve rapidly in the next decade, powered by Salesforce’s ecosystem:

- Connected Vehicles (IoT): Car usage data feeding into demand signals.

- Digital Twins: Simulating production and demand in parallel.

- AI-Driven Personalization: Forecasting customer preferences at a micro level.

- Sustainability Alignment: Forecasting tied to carbon-neutral targets.

According to Capgemini, over 70% of OEMs plan to integrate AI into demand forecasting by 2027 — Salesforce is at the forefront of this transition.

Conclusion

Demand forecasting is no longer a back-office process — it is the foundation of profitability and competitiveness in automotive manufacturing. Salesforce Manufacturing Cloud enables OEMs to:

- Improve forecast accuracy by 20–30% with account-based and AI-driven methods

- Align production with real-time dealer signals

- Reduce disputes with transparent forecasting dashboards

- Enable agility with scenario planning and “what-if” modeling

In a rapidly evolving market, from EV adoption to supply chain shocks, Salesforce Manufacturing Cloud empowers automotive manufacturers to forecast with confidence, plan with agility, and deliver with precision.

? Ready to transform your automotive forecasting strategy?

? [Book a Manufacturing Cloud Strategy Session with Perigeon]