Table of content

Introduction

The Industrial Equipment & Machinery Landscape

Why Sales & Operations Alignment Matters

Challenges Faced by Industrial Equipment Manufacturers

How Salesforce Manufacturing Cloud Unifies Sales & Operations

Case Study: Industrial Equipment OEM Transformation with Salesforce

The Future of Unified Sales & Operations in Industrial Manufacturing

Conclusion

Introduction

The industrial equipment and machinery industry powers modern economies — from heavy construction cranes and mining machines to factory automation tools and turbines. The sector is projected to surpass $1 trillion globally by 2030 (Statista, 2025).

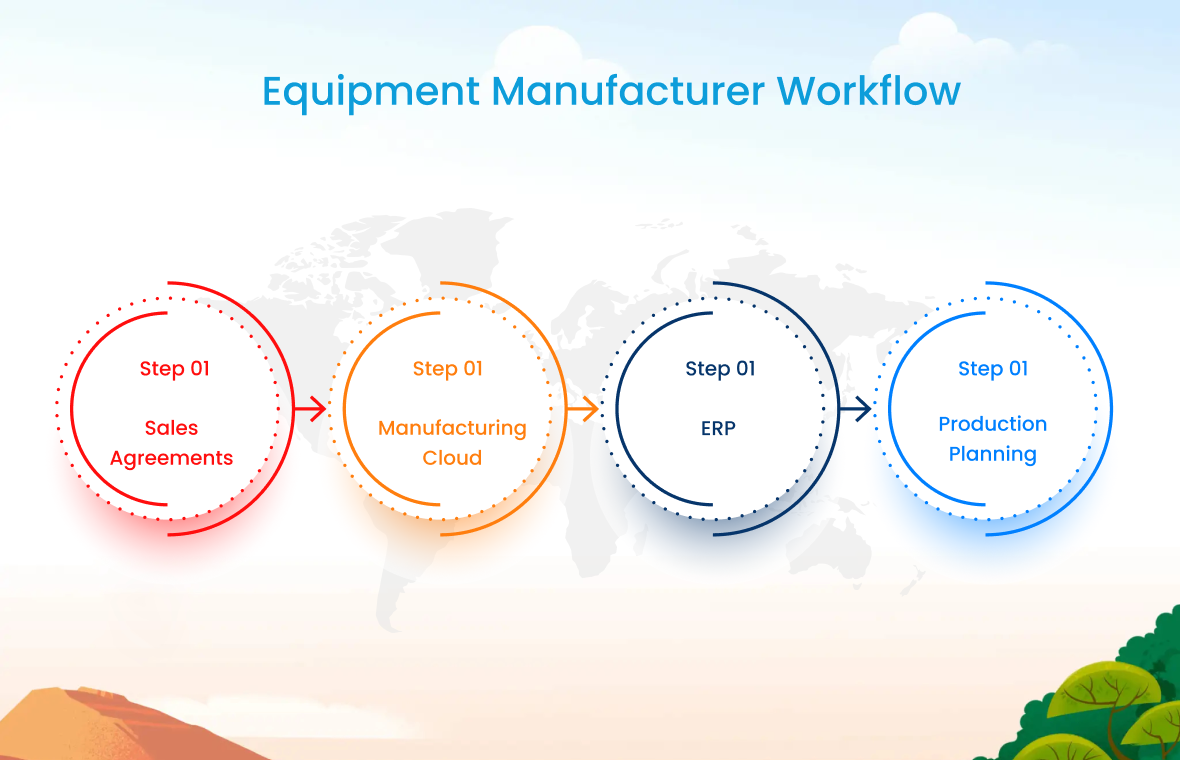

Despite its scale, many manufacturers struggle to align sales and operations. Sales agreements are often managed in CRMs, while production runs on ERP and yard systems. The disconnect results in inaccurate forecasts, production bottlenecks, and revenue leakage.

A 2024 Deloitte study revealed that over 50% of industrial equipment OEMs face margin erosion due to poor sales–operations alignment.

Salesforce Manufacturing Cloud bridges this gap by providing a single platform that unifies sales agreements, forecasting, production planning, and dealer collaboration — ensuring predictable revenue and operational efficiency.

The Industrial Equipment & Machinery Landscape

- Key Segments: Heavy construction equipment, mining machinery, turbines, industrial automation systems, agricultural machinery.

- Business Model: OEMs → Dealer/Distributor networks → End-users.

- Revenue Mix: Equipment sales + aftermarket services & spare parts.

- Customer Base: Governments, contractors, manufacturers, and utilities.

? Success in this sector requires tight integration between sales commitments and operational delivery.

Why Sales & Operations Alignment Matters

- Predictable Revenue → Ensures OEMs hit growth targets consistently.

- Operational Efficiency → Aligns production capacity with real demand.

- Dealer Trust → Dealers gain confidence through transparent commitments.

- Resilience → Better preparedness for economic and supply chain shocks.

Without alignment, OEMs risk excess inventory, delayed projects, and strained dealer relationships.

Challenges Faced by Industrial Equipment Manufacturers

1. Long Sales Cycles & Capital-Intensive Deals

- Sales cycles often run 12–24 months.

- Misaligned forecasts disrupt production planning.

2. Dealer & Distributor Dependency

- Global OEMs rely heavily on independent dealer networks.

- Lack of real-time visibility into dealer commitments creates risk.

3. Complex Sales Agreements with Rebates & Service Clauses

- Agreements include rebates, warranties, and bundled service contracts.

- Manual tracking causes disputes and revenue leakage.

4. Forecasting & Production Misalignment

- Production runs on outdated forecasts.

- Misalignment leads to either idle capacity or shortages.

5. Data Silos Across Sales, ERP & Service Systems

- Sales in CRM, production in ERP, service in legacy tools.

- No single source of truth for decision-making.

How Salesforce Manufacturing Cloud Unifies Sales & Operations

1. Centralized Sales Agreements Repository

- Stores contracts digitally in Salesforce.

- Links revenue commitments directly with production planning.

- Reduces disputes by ensuring shared visibility.

2. Account-Based Forecasting for Accuracy

- Forecasts demand at dealer/account level.

- Provides granular insights into regional demand.

- Improves accuracy by 20–30% vs. traditional forecasting.

3. ERP & Production System Integration

- Integrates Salesforce with ERP platforms (SAP, Oracle, Microsoft).

- Aligns production schedules with live sales commitments.

4. Real-Time Performance Dashboards

- Dashboards show:

- Dealer commitments vs. actuals

- Production capacity utilization

- Backlogs and bottlenecks

5. Dealer & Distributor Collaboration Portals

- Experience Cloud portals enable dealers to:

- View agreements and rebates

- Access updated forecasts

- Submit demand changes directly

6. AI-Powered Insights for Alignment

- Einstein AI predicts:

- Which dealers may miss commitments

- Where production bottlenecks may occur

- Opportunities for upselling service contracts

Case Study: Industrial Equipment OEM Transformation with Salesforce

A mining equipment OEM faced:

-

- Forecast deviations above 25%.

- Frequent disputes with dealers over rebates.

After Salesforce:

- Forecast accuracy improved to 93%.

- Dispute resolution time reduced by 60%.

- Production planning aligned directly with dealer commitments.

The Future of Unified Sales & Operations in Industrial Manufacturing

- Digital Twin Machines → Simulating production vs. demand.

- Blockchain Contracts → Tamper-proof OEM–dealer agreements.

- AI-Powered Predictive Maintenance → Integrating aftermarket service into forecasts.

- Sustainability Dashboards → Carbon tracking embedded in contracts.

Conclusion

For industrial equipment OEMs, unifying sales and operations is critical to profitability. Salesforce Manufacturing Cloud delivers:

- Centralized visibility into contracts

- Accurate account-based forecasting

- ERP integration for seamless planning

- Dealer portals for collaboration

- AI-driven insights for predictability

With Salesforce, manufacturers can transform complexity into predictability, efficiency, and competitive advantage.

⚙️ Ready to unify your sales & operations?

? [Book a Manufacturing Cloud Strategy Session with Perigeon]